Repair of electric power steering Opel Astra H

Cars of the German brand Opel are one of the most popular in Europe. A typical representative is the Astra H compact passenger car model, produced from 2004 to 2014. Many of these cars are still on the road because of the successful combination of practicality, reliability and technology. For example, the steering rack here is not the most standard, but at the same time very effective, electro-hydraulic. However, time takes its toll, and this unit often needs to be repaired. Let us briefly describe how it is done at STS Parts.

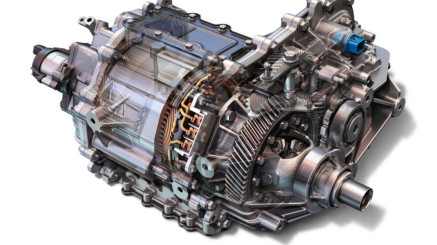

What is electro-hydraulic power steering

The principle of operation of an electro-hydraulic power steering rack is similar to a simple hydraulic one, only the pump (pump) is driven not through a belt drive from the pulley of the internal combustion engine, but from the on-board power supply system.

The steering mechanism with a combined electro-hydraulic drive combines the advantages of both schemes. It takes efficiency and power from hydraulics, and reduced fuel consumption from electricity (the electro-hydraulic rack and pinion pump does not work when driving in a straight line), compatibility with electronic systems, and control by the vehicle's control unit.

The disadvantages also apply to both systems. Not only are fluid leaks possible, as in a simple hydraulic steering rack. Since the electronics controlling the pump are located inside its housing, the liquid can easily get in and damage the control unit board or the stator winding of the electric pump - causing oxidation of the contacts or a short circuit inside.

Varieties and structure of the Opel Astra H electric power steering pump

Cars of this model were equipped with three types of pumps manufactured by two companies:

- TRW (two versions)

- ZF

The first variant, the TRW1 pump, has been fitted to Opel cars since 1998, in particular, the Astra G. Regardless of the variations, all pumps consist of the following parts

- casing

- O-ring;

- expansion tank

- distributor

- power hydraulic cylinder

- pressure regulator

- hoses and highway couplings.

- rotor

The booster pump is connected via a CAN bus, which makes it possible to interact with the car's control unit, ABS system and other components.

Typical pump problems and their signs

The main malfunctions can be divided into two groups:

- Moisture ingress into the pump casing.

- Damage to the motor windings due to increased loads.

In the first case, glands or gaskets that have lost their tightness are usually to blame, in the second case, the cause of the breakdown may be the driving style. Especially harmful to the power steering pump is the manner of holding the steering wheel in the extreme position for a long time. In this case, the control windows of the steering rack are blocked, and the current on the motor windings reaches 50-70 amps. The control links often do not withstand such loads and burn out, the pump fails.

Signs of an amplifier breakdown will be the appearance of a yellow icon in the form of a steering wheel with an exclamation point on the dashboard. At the same time or a little later, the steering wheel is likely to become heavier - the electronics will turn off the pump. But even before the indication appears, symptoms such as

- reverse jolts from the steering wheel

- biting the steering wheel while turning;

- extraneous sounds (noise, squeaking) from under the hood

- unstable operation of the system as a whole.

All of this is at least a reason to sign up for steering diagnostics at STS Parts.

Progress of repair of electric power steering

We repair the power steering rack in several stages. We start with a preliminary diagnosis of the car using a scanner. Sometimes it is enough to change the fuse or properly fix the terminal on the generator to restore the unit's performance.

If the diagnostics show that the problem is serious, we dismantle the pump for the purpose of defecting it. First, we wash it and clean it in a sandblaster.

After the diagnosis, the pump is dismantled.

Next is disassembly with the removal of the tank neck (also known as the top cover) and the pumping element. Depending on the pump model, both can be dismantled in different ways. Note that this is only the first of many nuances that are often known only to specialists. Therefore, we strongly recommend that you do not repair the electric power steering pump yourself or entrust it to unqualified mechanics.

Next, remove the bottom cover of the pump and rotor. This provides a view of the stator winding and control electronics.

Next, dismantle the pump's electronic unit, diagnose it and, if necessary, restore it.

Assemble the lower part in the reverse order and proceed to the analysis of the components of the swing mechanism. Restore them using the parts of the repair kit.

All the components of the tilt mechanism are assembled in the opposite order.

Assemble the electric hydraulic booster pump, paint the body and test it on the bench. It should deliver a pressure of 110 bar.

And the test of the pump.

Installation of the unit on the car.

If for some reason it turns out that the pump is not repairable, we will install a refurbished unit from our large exchange fund. One way or another, STS.Parts customers will receive a refurbished steering rack that will be in no way inferior to the original part, and in terms of further maintainability, it will even surpass it. And this is at a much lower price.