What to do if your electric vehicle's motor jams

What to do if your electric car's motor jams

Electric cars have a lot of pluses. They're environmentally friendly, they can be fuelled at home from a socket. They're also much simpler than cars with classic internal combustion engines. Even motor failures are most often down to bearing wear or fluid ingress. Now let's remember how many possible faults an internal combustion engine can have.

The worst dream of the owner of a petrol or diesel car – is the engine jamming. We won't list the reasons why this happens. Let's just say that it happens to cars with electric motors too. And here's how we deal with it.

Repairing a jammed Continental electric motor

This motor came to our station separately from the car, so it's hard to even tell which model of car we're talking about. However, judging by the markings on the motor itself, it appears to be a unit for one of the Peugeot or Citroen models, and if you take the hieroglyphics into account, it was made for the Chinese market. (It later turned out to be an Opel).

The car was involved in a minor accident, but after the accident, the engine stopped spinning, jammed. For this reason, the motor was removed and sent to us for repair. Initial inspection showed that the bearings were individually spinning and did not even seem to be affected, no noise. We will have to disassemble the motor to find the cause.

We unscrewed the covers from the motor and the bearing information was confirmed. However, the rotor is still firmly seated in the stator, not spinning. My intuition tells me that the root of the problem lies in the motor design. Here the motors are not asynchronous, as on Tesla, but, as on the previously repaired to us Korean-made cars, Kia/Hyundai, synchronous. Their difference – is the neodymium magnets used in the rotors. These magnets are so strong that the motor is difficult to work with – it constantly attracts all the objects that happen to be nearby.

It seems that this time that «object» was the stator itself. A hydraulic press had to be used to separate the two parts of the motor. And now the inseparable rotor and stator were finally separated, and we began to examine them. On the surface of the rotor we found a stain, which looked like rust rubbed off with sandpaper. However, there was neither rust nor moisture anywhere. There are similar marks on the stator too, plus

Surfacing on a few of the plates.

Probably as a result of the accident, due to loss of alignment, the rotor started touching the stator and therefore became magnetised. While the car was travelling, it was still spinning, but as soon as the motor stopped, the hot parts melted together. This version is also confirmed by spots of white colour on the inner surfaces of the covers – apparently from overheating.

We cleaned up all of the gouges and contact marks with sandpaper and a flap wheel for the grinder, smoothed, polished and cleaned all of the dust and chips with compressed air. After that we wrapped the rotor with thick polythene film to prevent it from being magnetised to the stator. An old water bottle was used to do this, so it was heated in the manner of heat shrinking to make it fit tightly to the metal.

The rotor wrapped in polythene went inside the stator easily, we then clamped one of the covers on to centre it thus avoiding magnetisation, removed the film and put the second cover on. The motor spun easily by hand, so we considered the repair a success and returned it to the customer – that was the agreement. Although, given some backlash after the accident, we advised him to replace the motor in due course.

Peugeot/Citroen starter-generator stuck

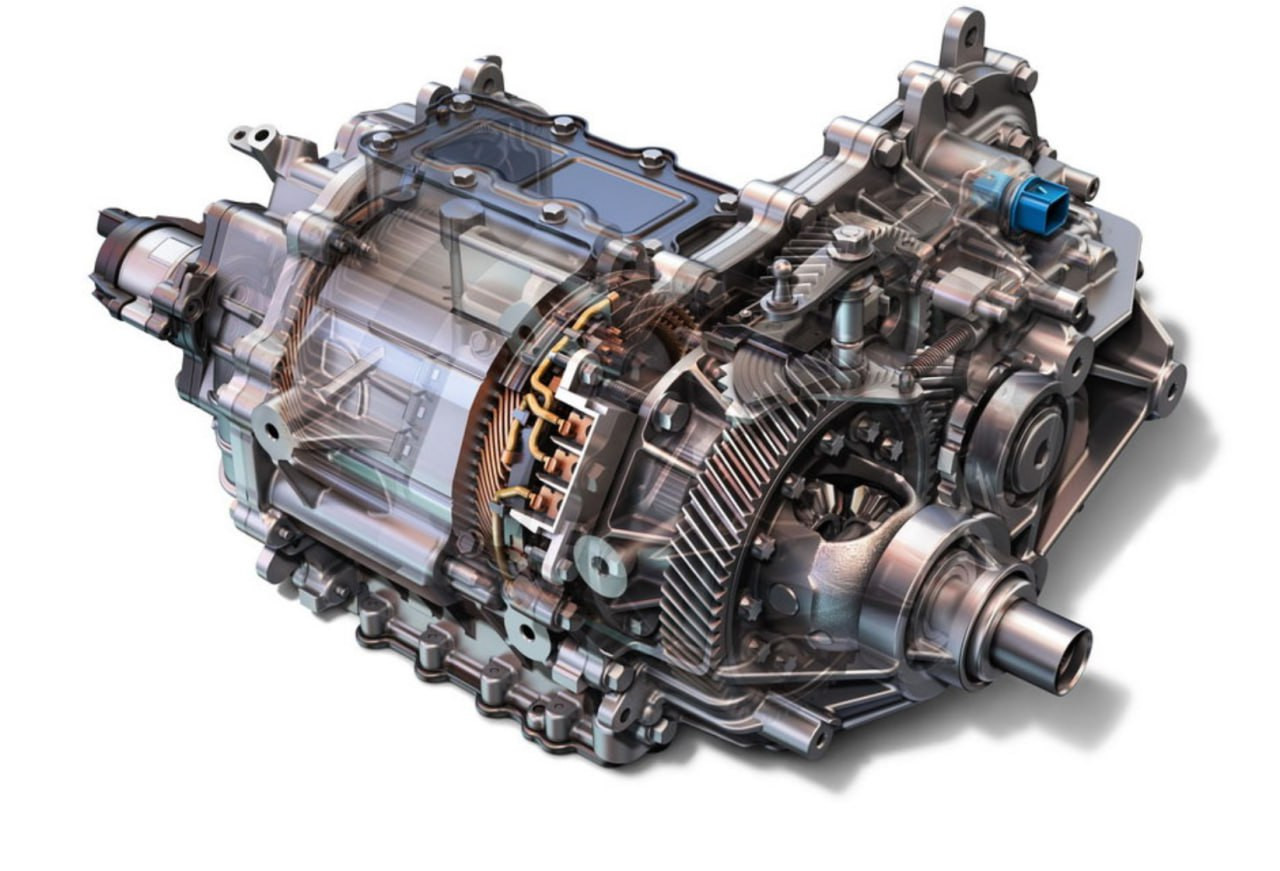

Besides the big motors of «pure» electric cars, we also repair components of hybrid cars. One of these components came to us with similar symptoms: the electric motor was stuck. Just as in the first case, the motor was sent to us separately from the car, which is logical: it is impossible to move in case of such a breakdown. And another coincidence – it is also a unit from Peugeot/Citroen.

We disassembled this starter generator, which is a three phase liquid cooled electric motor. When we removed the resolver, we smelled the odour of burning electrics. Inside the stator we had a surprise in the form of a collapsed bearing. There was a lot of smeared grease and shavings, but the insides of the motor were intact as the broken cage was plastic.

At first it looked like replacing the bearing would be enough to get the starter generator back up and running, but a detailed examination revealed damage to the stator winding. Apparently, it would have to be rewound. Not to worry, we at STS.Parts know how to do it, and we follow all factory procedures.

Conclusions

As you can see, «wedge» electric motor – quite not terrible, quite solvable problem. The main thing – ask for help from professionals who know their business well and have a lot of experience in repair.

Consider the following