Replacing bearings in the Hyundai Ioniq EV electric motor

Korean electric car manufacturers are steadily improving the performance and quality of their vehicles. In many aspects, they have already overtaken the leading carmakers. However, some problems still exist. One of them, with which our customers most often come to us, is noise in the engine or gearbox. Let's tell you how we fight it.

Hyundai Ioniq EV repair

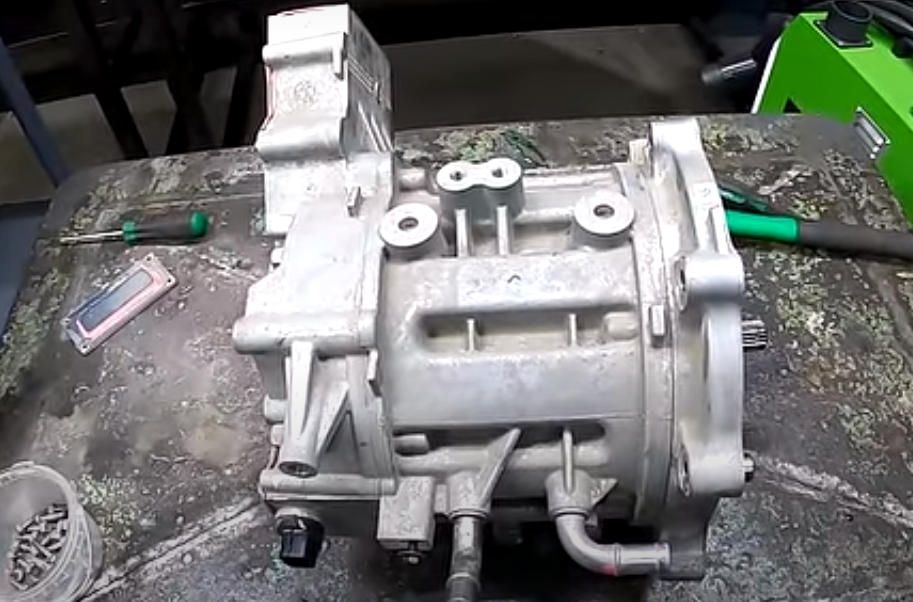

An electric car came to our service station with a complaint of engine noise. The mileage is 114 thousand kilometres. The car was lifted on a hoist, we found out that the noise was coming from the engine, from the side opposite to the gearbox.

It was decided to remove the motor, disassemble it and look for the cause. Note that on this model of car the electric motor itself is very easy to remove. It is not even necessary to unscrew the wheel drives, as they remain together with the gearbox. The motor is very compact and quite light, especially compared to the internal combustion engine. This is despite the fact that it produces 120bhp and almost 300Nm of torque.

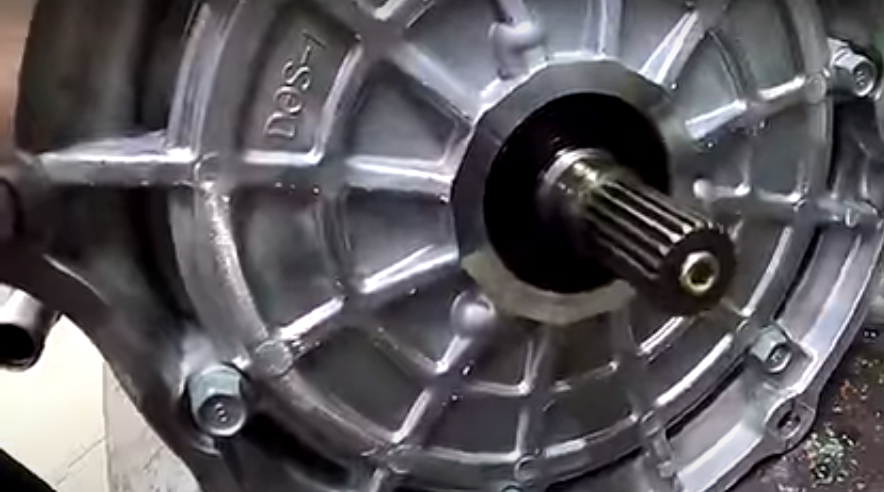

The top cover has been removed and the winding is already visible. Now we will remove the front cover of the motor and get to the bearing. In the meantime, let's check with a screwdriver whether our diagnosis that the noise comes from the bearing is correct. On the shaft, in the center, there is a hexagonal plug. There we insert the appropriate nozzle and start turning the electric motor. Yes, we were not mistaken, the noise is there, and just where we heard it during the test on the lift.

In fact, there are no major difficulties in disassembling the Ioniq EV motor. The most difficult part is dismantling the resolver (rotary angle sensor), which is mounted on the rotor shaft. Its sprocket is held on the keyway, but, judging by the colour of the metal rust, is fixed hot: heated and put on the rotor shaft. To remove the old bearing and install a new one, it will have to be removed. So, we will have to act in the same way as those who used to assemble the motor.

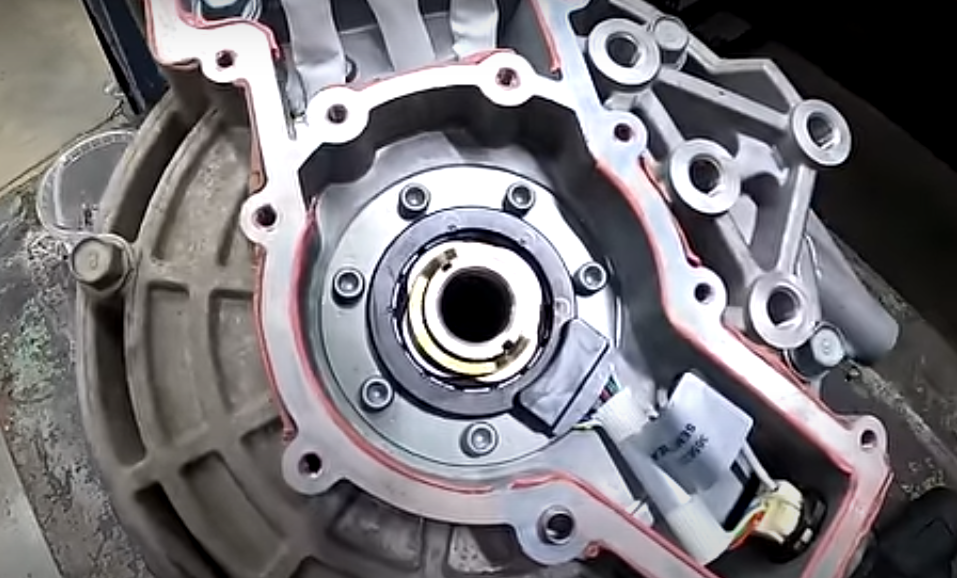

Unscrew the three phases and the cover, then carefully knock it off with a mallet. Now we can see what the motor cooling looks like. Its jacket is outside the stator. The rotor is not cooled, at least antifreeze does not pass through it. And there is a metal gasket, similar to the cylinder head gasket in a car with an internal combustion engine. The only difference is that here it is not multi-layer, but single-layer. We doubt that we will find such a new one, as the manufacturer does not provide disassembly of electric motors, so we will probably lubricate it with sealant. We would not like that after our repair antifreeze would get inside the motor.

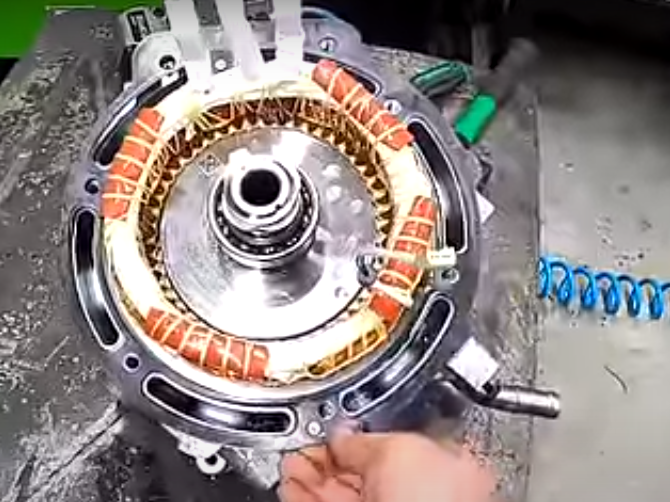

There is one point to clarify here. Unlike Tesla cars, which have asynchronous motors with a closed circuit in the rotor (the so-called "squirrel cage"), the Hyundai Ioniq EV has a synchronous electric motor, and the rotor has neodymium magnets. Therefore, it is very strongly magnetised to the stator, which sometimes causes some problems. For example, the magnet makes it very difficult to disassemble the motor and pull out the rotor. And also the powerful magnets of the rotor attract everything iron from the table: metal dust, tools, fasteners, so you need to be careful when working with the rotor Ioniq.... and preferably have a titanium spanner.

The magnets also add weight to the Hyundai rotor. It is noticeably heavier than Tesla's, even though it is smaller in size

We ordered new bearings to replace the one that was humming, and also decided to change others in the motor as well. And now our order has arrived, but there is one small problem. In terms of the diameters of the cages - inner and outer - the new parts are absolutely identical to those that stood before. In general, this is a standard size, exactly the same bearings are used, for example, in Tesla motors. However, there they have ceramic balls, while we had steel ones, so we bought them.

But the height of Hyundai bearings is unusual - 15 mm. We could not find such bearings anywhere. Therefore, we ordered 14 mm bearings and will get out of the situation with the help of spacer rings, we will compensate the height with them.

The motor is assembled, and we again conducted a "test drive" on the table with a screwdriver. No noise. Now we can install the motor on the car

The motor is installed, you can assemble the car and drive it on the road. There are no noises, everything is quiet - that's how an electric car engine should work. Now on arrival we check the antifreeze level, top up if necessary, and the car can be handed over to the owner.

Conclusions

There are no cars that never break down. Against the background of other advantages of Hyundai electric cars, bearing failure is certainly a nuisance, but not a tragedy at all. Such malfunctions can and should be repaired. It is not necessary to change the whole motor and pay huge money. You just need to turn to professionals - to us at STS.Parts. Our team of experts conducts thorough diagnostics of electric vehicle motors, allowing us to accurately identify the problem and effectively resolve it, saving you time and money.