Turbine diagnostics and repair

Where to find us

What Turbines Can Be Repaired at STS

A turbocharger, or as it is usually called more simply, a turbine, is an important engine component responsible for increasing power and torque. Turbochargers are used in the vast majority of modern diesel vehicles and a significant portion of gasoline cars. Due to their design features, this component has to work in very difficult conditions, so periodic turbocharger restoration in Warsaw is sometimes simply necessary. How can you determine that the component has failed and where to perform turbine repairs in Warsaw?

Essentially, the company regenerates any types of turbochargers used in both cars and other equipment: on tractors, boats and motorboats, and even in tanks. The operating principle of turbines in most internal combustion engines is roughly similar: they usually consist of two impellers connected by a common shaft, each placed in its own round housing (often called a "scroll").

Into one "scroll" exhaust gases flow, which rotate the "hot" impeller, and into the other, "cold" one, the impeller is designed to draw in external air and supply it under pressure to the engine's intake manifold. Increasing oxygen supply also allows increasing fuel supply, and thus enhancing engine power and efficiency. Turbocharged engines, especially diesel, have the highest efficiency among all internal combustion engines. Therefore, turbocharger service in Warsaw is a very sought-after service.

Automotive turbines can be divided into two classes according to the geometric features of their internals:

- Conventional, with stationary impellers of unchanging shape;

- Turbines with variable geometry.

The second type is equipped with an additional ring with movable blades of a special aerodynamic shape, which increases boost efficiency and eliminates turbocharging drawbacks (so-called turbo lag).

Furthermore, there are several engine turbocharging configurations:

- Single turbocharging – the most common type.

- Biturbo – sequential installation of two compressors. In this type, one turbine can be main, and the other auxiliary.

- Twin turbo. Parallel placement of two identical units (for example, with a V-type layout).

- Quad turbo. A variant of the previous type for multi-cylinder engines of sports cars.

- Twin biturbo. Double biturbo. Like the previous type, it is encountered very rarely.

In general, turbocharger repair in Warsaw of any types and configurations does not have significant differences and can be qualitatively performed in a professional workshop equipped with specialized equipment.

Turbine Malfunctions That Can Be Repaired at STS

Most turbocharger failures have their root cause in the very complex conditions in which the component must work. The key is the temperature difference between the "hot" and "cold" scrolls. Into the first impeller, heated exhaust gases flow directly from the combustion chamber, into the second – atmospheric air, often additionally cooled in the intercooler to improve mixture combustion quality.

Main Signs of Turbocharger Failure:

- Power drop and deterioration of vehicle dynamics;

- Reduction of boost pressure level (if sensor and indicator are present);

- Increased motor oil consumption;

- Blue or black smoke from the exhaust pipe;

- Squealing in the turbine area.

Their cause can be a quite wide range of malfunctions that can be combined into several groups:

- Turbocharger housing damage – cracks, chips, scratches.

- Destruction of the turbine wheel and blades.

- Failure of turbine components: shaft bending or destruction, compressor wheel, nozzle apparatus blades, bearings.

- Bypass valve (Wastegate) malfunctions.

- Actuator and position sensor failures.

All these problems are caused by both overheating and the use of low-quality motor oil or its untimely replacement, foreign objects getting inside the turbine, as well as natural wear and aging of turbocharger components.

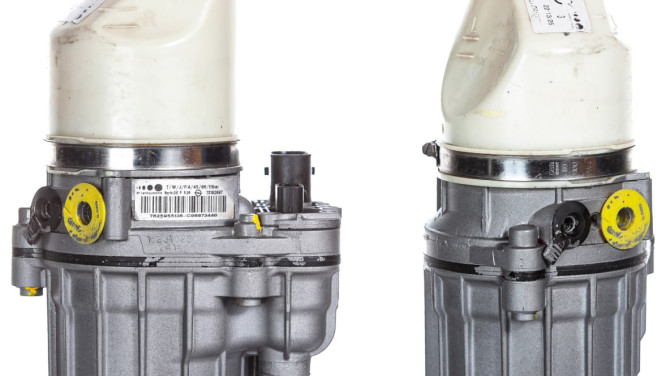

Turbocharger Replacement or Restoration in Warsaw – What to Choose

A turbine is not the cheapest car part, so when repairing, you need to consider the nature and complexity of the malfunction. Small breakdowns of auxiliary parts such as sensors, bearings, and similar ones are solved by disassembling the turbine and do not require its replacement. However, in case of serious housing damage or its critical wear, the turbocharger should preferably be replaced. But even then, you can find optimal problem-solving options – for example, replacing the faulty turbine with a quality-restored one from the STS exchange fund.

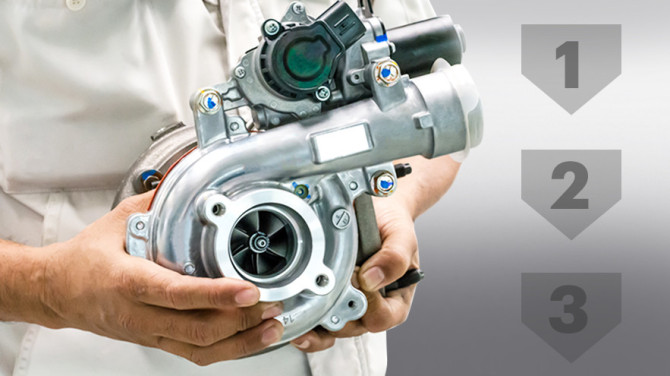

Turbocharger Restoration Process

Turbine repair in Warsaw at our workshop consists of the following stages:

- Node dismantling and transfer to the repair department.

- Housing cleaning.

- Defect analysis to determine the cause of the failure.

- Electronic component diagnostics.

- Replacement of damaged and worn parts.

- Balancing and adjustment of the unit on professional equipment.

After turbine restoration in Warsaw, they can be installed in a car using a new gasket set of our own production and assembly. As a result, the client receives a completely overhauled compressor, identical to a new one both in terms of performance and residual resource. STS provides a 6-month warranty for all its work and spare parts used.

Turbine regeneration prices in Warsaw depend on the complexity of work and vehicle modification. However, in general, it is much more advantageous and cheaper than buying and installing a new unit.