Repair of the Dacia Spring electric car: a real case study from STS

DACIA Spring

Dacia Spring is one of the most popular budget electric cars in Europe. It is often referred to as ‘second only to Tesla’ because this model has become the most popular alternative for those who want a simple, economical and reliable electric car. The car is manufactured in Europe, has a simple design without excessive ‘smart’ systems, and is therefore easy to operate and maintain.

However, even the most reliable cars are not immune to user errors or accidental breakdowns. In such situations, the quality of service is crucial: how quickly and professionally the technicians can restore the electric car to working order. That is why customers turn to STS in Warsaw — a service that specialises in complex repairs of electric cars.

Solving problems with starting a 2017 Dacia Spring electric car.

The owner of a Dacia Spring contacted us with a complaint: the car would not start or move. At first glance, the cause of the malfunction could be attributed to many factors — from a simple battery discharge to a serious failure in the electronics.

STS specialists began by checking the condition of the 12-volt battery with a special tester. At the same time, they checked the key electrical components of the car to rule out the possibility of other malfunctions. This allowed them to quickly localise the problem.

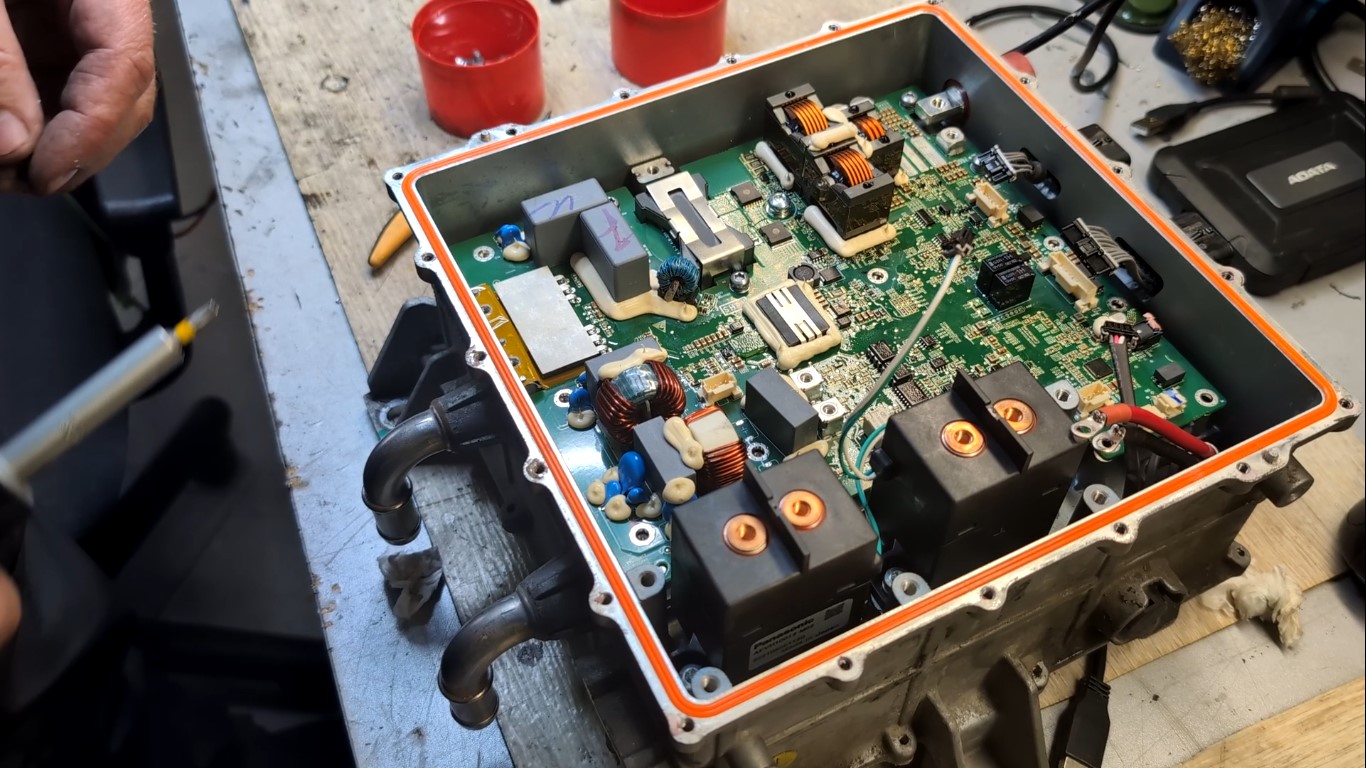

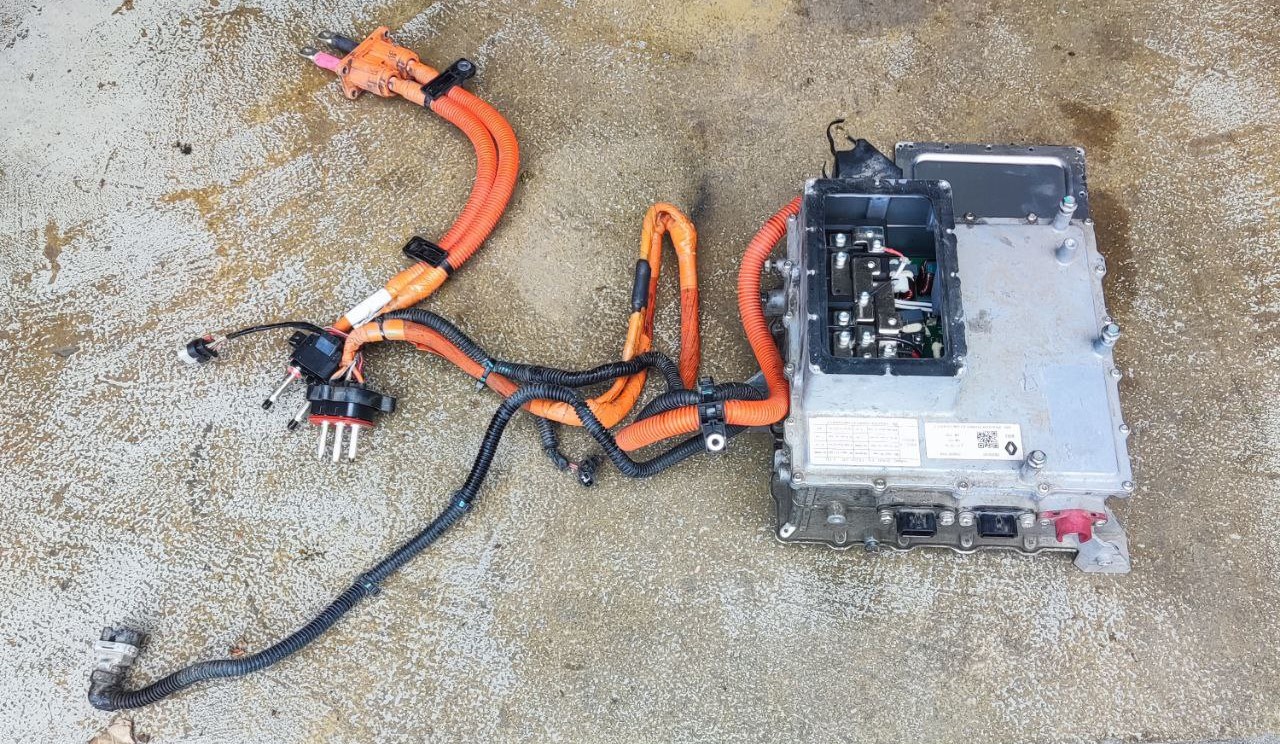

It turned out that the 12-volt battery was completely discharged. During previous manipulations, the battery terminals were mixed up (reversed polarity), which resulted in the failure of the DC/DC converter, which in the Dacia Spring is combined in one unit with the charger. This is a design feature of this model, which is related, on the one hand, to its compactness and, on the other hand, to its budget class.

Repair process

We agreed with the customer to dismantle the damaged unit. During the work, we discovered an important detail:

- two power cables were secured with bolts, so they were removed without any problems;

- but the third was soldered and insulated with heat shrink tubing, which made removal much more difficult.

Despite these difficulties, we managed to remove the unit carefully.

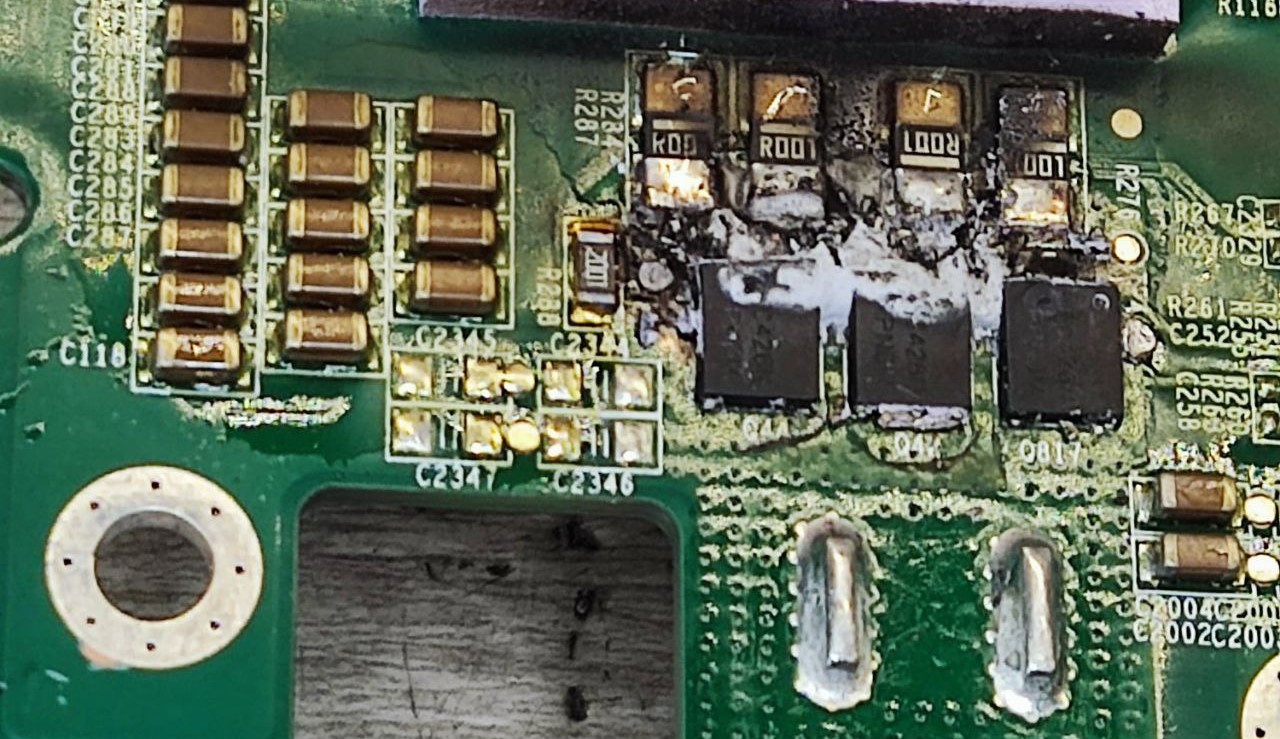

After disassembling the DC/DC converter, we found blown diodes on the board. Fortunately, all the necessary components were available in stock, so we immediately replaced the diodes.

Next, we conducted the first test: we connected the unit without installing it in its regular place, temporarily placing the wires on top, above the front grille. This allowed us to quickly assess the performance of the system without completely reassembling the car.

The result was positive:

- the high-voltage battery charged at almost 7A;

- the antifreeze circulated in the cooling system;

- the voltage on the 12V battery during charging was 14.4V.

After that, the unit was finally assembled and installed in place. Additionally, the wires to the charging port lock were restored using modern insulation materials – glue that hardens under ultraviolet light.

The final check confirmed that the car was fully charged and ready for operation.

Why choose STS

Today in Europe, the number of electric vehicles is growing every year, but it is quite difficult to find a professional workshop that specialises in repairs rather than just superficial maintenance. Most services are limited to replacing entire units, which means high costs for the owner.

There is one exception in Warsaw – the STS company. We specialise in the restoration of complex electronic and power units of electric vehicles, including components such as DC/DC converters, charging modules, inverters, high-voltage batteries and others.

Our key advantages:

- Experience: many years of practice in repairing electric cars and a deep understanding of their specifics.

- Team: certified technicians who can work with high-voltage systems and complex electronics.

- Equipment: modern diagnostic facilities, special test benches and components, including our own MSG brand.

We are not afraid of ‘difficult’ cases and often repair units that other workshops recommend replacing with new ones. This is what makes STS in Warsaw a reliable partner for electric vehicle owners.

Warranty

We provide a 6-month warranty on all work performed and materials used. This means that the customer can be confident in the quality of the repair and the reliability of the car's further operation.

How to avoid similar problems in the future

The cause of a 12V battery discharge is difficult to determine immediately. There have been cases where electric cars ‘woke up’ due to communication with an external server and gradually drained the battery. Although we are not aware of any similar cases specifically involving the Dacia Spring, they cannot be completely ruled out.

What the owner should do:

- regularly check the condition of the 12V battery;

- remember that electric cars do not have a low-voltage battery discharge indicator;

- if you notice any suspicious symptoms, contact professionals — for example, at STS in Warsaw.

So, in this case, the Dacia Spring malfunction was caused by mixed-up 12V battery terminals and a faulty DC/DC+charger unit. Thanks to prompt diagnostics, the availability of spare parts and the experience of our technicians, we were able to quickly restore the car's performance without the need for expensive replacements of the entire unit.

STS (Warsaw) is more than just a regular service workshop. We help electric vehicle owners solve complex technical problems where others would simply advise them to ‘replace the unit’. And most importantly, we guarantee that after our repairs, the car will run smoothly and reliably.