Repair of the high voltage battery of the Peugeot e-208

PEUGEOT 208

The Peugeot e-208 is a popular city electric car with a modern lithium-ion battery with a capacity of about 50 kWh. The battery design is quite reliable, but even in such systems, individual elements can fail, which can completely block the charging process. It was precisely this situation that prompted the owner of this car to contact the STS workshop in Warsaw.

Signs of malfunction

Our customer's problem arose suddenly — during a routine charge at a station, when the charge level reached almost 100%. At that moment, the second level of overvoltage protection was activated, which shut down the charging process. The charging gun remained connected, but no more energy was supplied. The owner, without losing his composure, decided to check the situation — he slightly discharged the battery while driving and tried to connect to other charging stations. However, the result was the same everywhere: the car worked and moved, but categorically refused to charge.

Diagnostics

After contacting STS, the specialists began with a thorough diagnosis of the high-voltage system. Using specialised equipment, they performed the following:

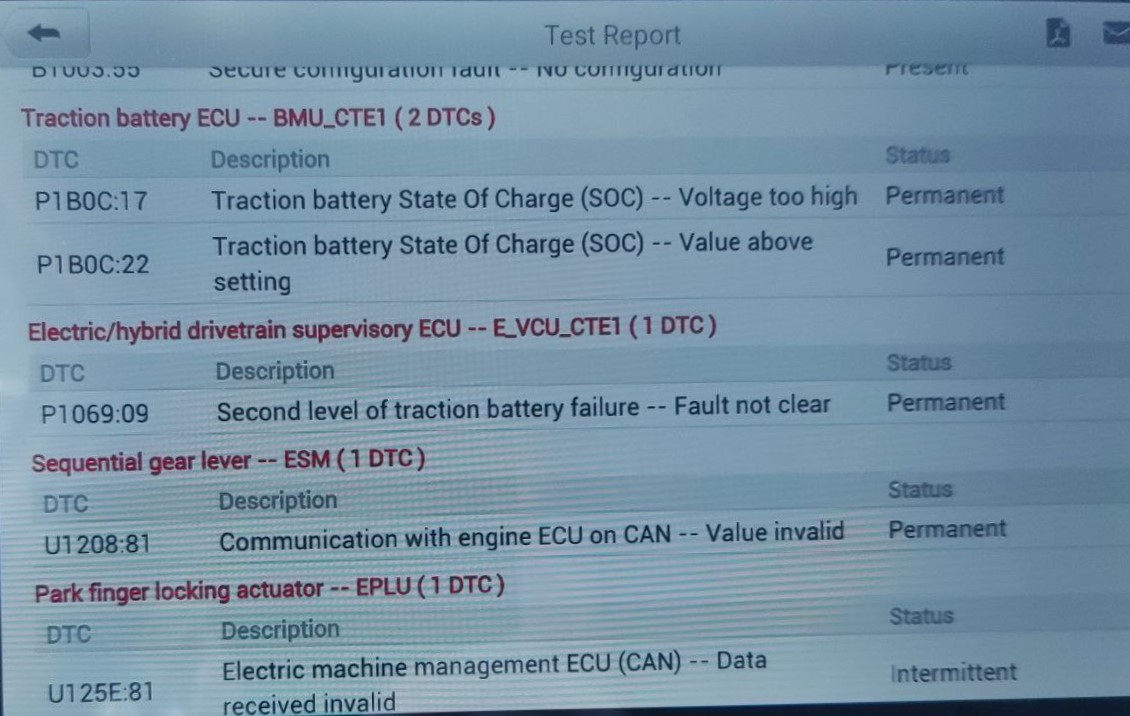

- BMS (Battery Management System) error reading — the system recorded a fault code corresponding to excess voltage in one of the cells;

- checking the condition of individual battery cells, of which there are over a hundred in the Peugeot e-208;

- measuring the voltage and internal resistance of each cell.

During the analysis, it was found that one of the cells was behaving erratically. At the moment of charging, it showed more than 4.2 V per cell, which exceeded the safe limit. At the same time, under load — while driving — the voltage on it, on the contrary, dropped by 70-80 mV compared to the rest. This behaviour indicated internal changes in the structure of the cell — an increase in internal resistance and a loss of capacity.

The cause was identified

The BMS, detecting this discrepancy, automatically activated its protection mechanism: it stopped charging and blocked the battery to prevent further damage. The cause was a faulty lithium cell, which disrupted the voltage balance in the entire unit.

Repair process

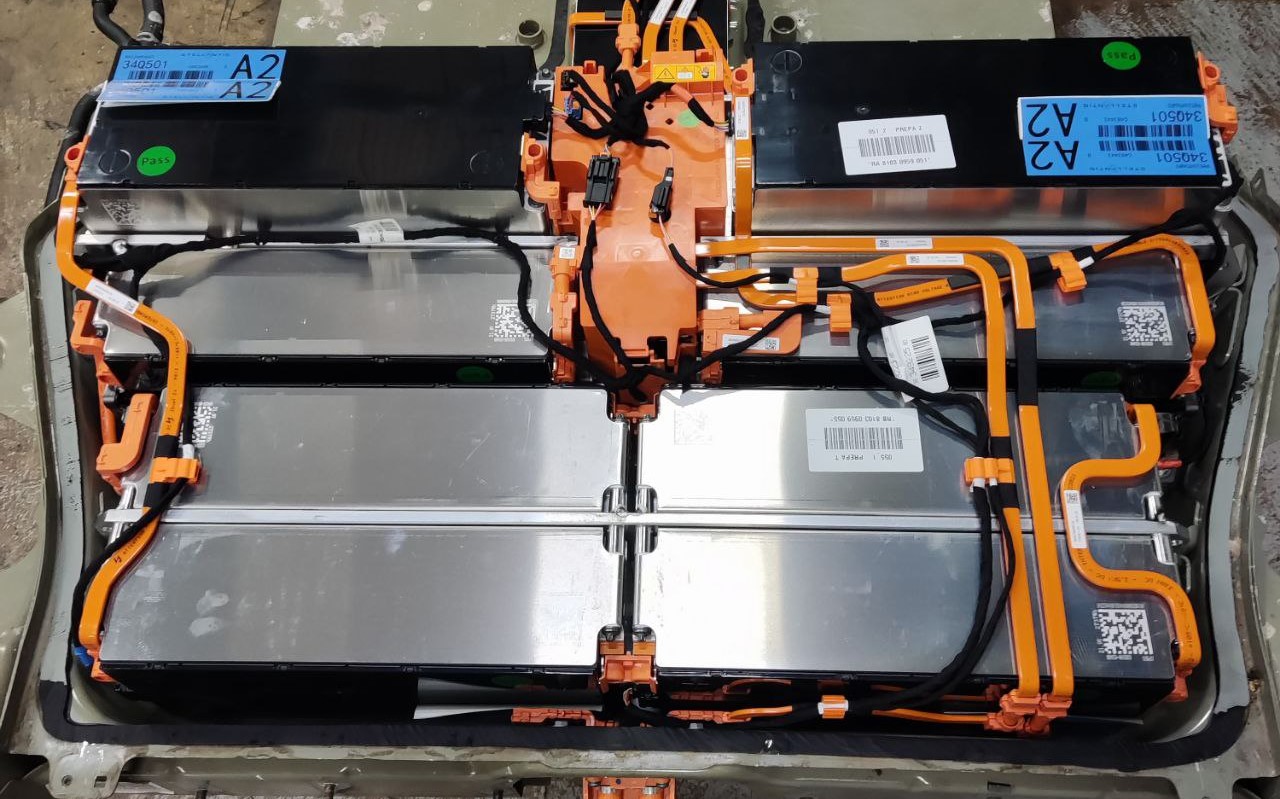

After consulting with the customer, STS specialists dismantled the high-voltage battery. The work was carried out in compliance with all safety requirements, as the system voltage exceeds 400 V.

Next, in sequence:

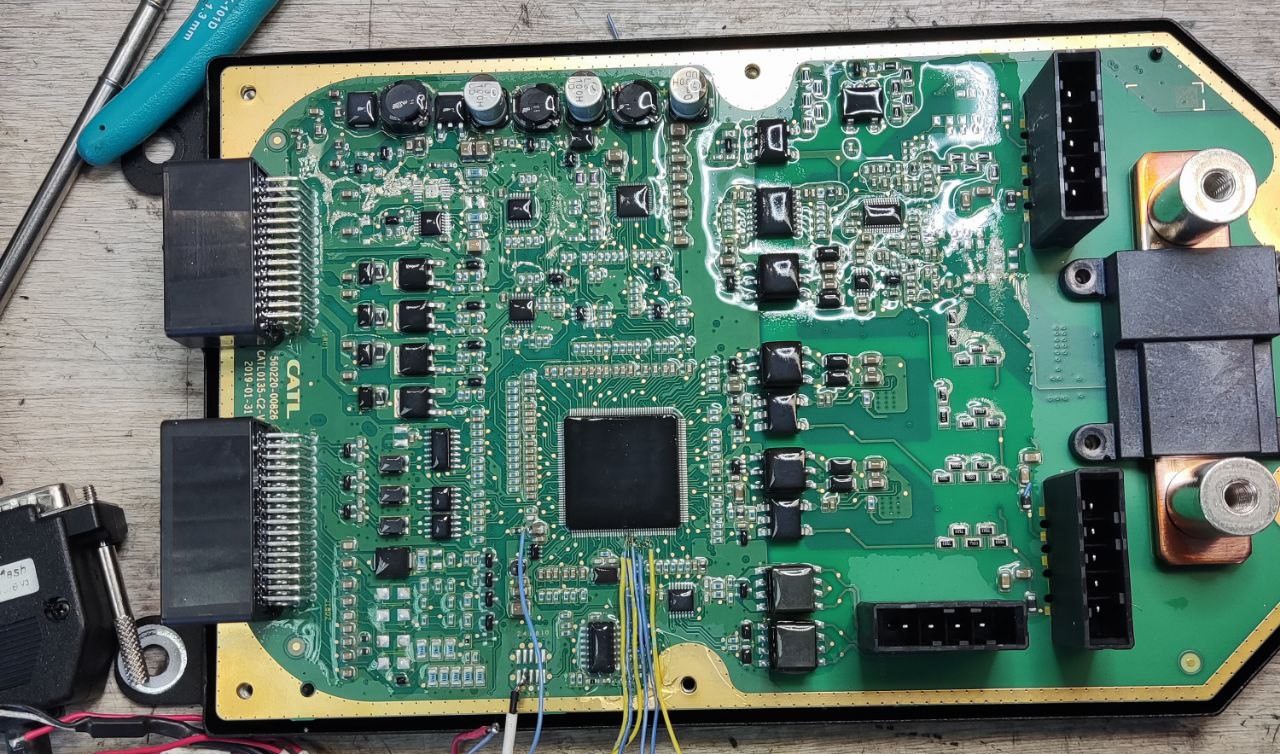

- The BMS was removed from the battery and the memory dump was read for further work.

- Attempts to remove the error programmatically were unsuccessful — the unit continued to store information about the overvoltage even after the codes were cleared.

- A decision was made to physically replace the damaged cell.

- A new cell with the appropriate capacity and characteristics was installed, after which the voltage was carefully balanced across all cells.

- A test charge was carried out on a special stand and load testing was performed.

After assembly, the battery underwent final checks — charging was restored, the voltage was stable, and the deviation between cells did not exceed a few millivolts.

Prevention tips

To extend the service life of your high-voltage battery, we recommend:

- Do not leave your car charging for a long time after reaching 100% charge, especially in high temperatures.

- regularly check the condition of the battery and BMS system at a certified service centre;

- use only serviceable charging stations with correct voltage control;

- in case of the slightest deviations in charging behaviour, contact specialists rather than experimenting on your own.

Why you should contact STS

The STS workshop in Warsaw has many years of experience working with systems from various brands — from hybrids to fully electric models. Our specialists have professional stands for testing, charging, balancing and diagnosing high-voltage batteries of all types — both lithium-ion and nickel-metal hydride. This makes it possible to detect defects at the level of individual cells, allowing batteries to be repaired without complete replacement, saving owners money.

STS provides a 6-month warranty on all work performed and components installed. Each repaired battery undergoes complete testing before being installed in a vehicle.

Customers choose STS for its professionalism, technical competence and responsible approach to each project.