Repair of high-voltage batteries of commercial electric vehicles Nissan eNV200

NISSAN e-NV200

Three different but similar cases with the same outcome

We were approached by a very interesting and challenging client. This is a well-known delivery service in Poland. They actively use Nissan eNV200 as their delivery vans. In addition to the economy and environmental friendliness of these vehicles, our client actively uses another advantage of electric vehicles: their low center of gravity. This is very important because the lion's share of parcels are large but lightweight boxes that require transport with a large internal volume. However, such vehicles are usually unstable and prone to wind resistance – but not in the case of electric cars, whose batteries serve as a reliable “anchor” that presses the tall van to the ground.

One of the main problems with commercial transport is high mileage. And in a large company, there is also the lack of a permanent “owner” for the vehicles. Drivers often change and do not always pass on the “medical history” of the vehicle. In the case of electric vehicles, there may also be chronic charging problems due to the desire to use the vehicles more efficiently. There is not always enough time for a full cycle, which inevitably affects the condition of the high-voltage batteries.

We received three Nissan E-NV200 electric vehicles with the maximum configuration: long wheelbase and maximum height. According to the customer, all three had battery problems.

The situation in the first car was classic. There were problems with several (specifically four) modules, we found the problematic components and replaced them. We balanced and recharged the high-voltage battery and returned the serviceable vehicle to the customer's representative.

The situation with the second vehicle was more interesting. The battery malfunction was not confirmed, as our tests showed the opposite. This vehicle was also returned to the customer — even STS.Electro cannot repair serviceable vehicles.

The story with the third Nissan E-NV200 was completely unusual. It was brought to us for repair with a dismantled battery — the modules were lying in the back. Apparently, the customer thought this would facilitate the BMS repair process, but in fact, it had the opposite effect. This case is a good example of how poorly electric vehicle owners sometimes understand the specifics of repairing their cars.

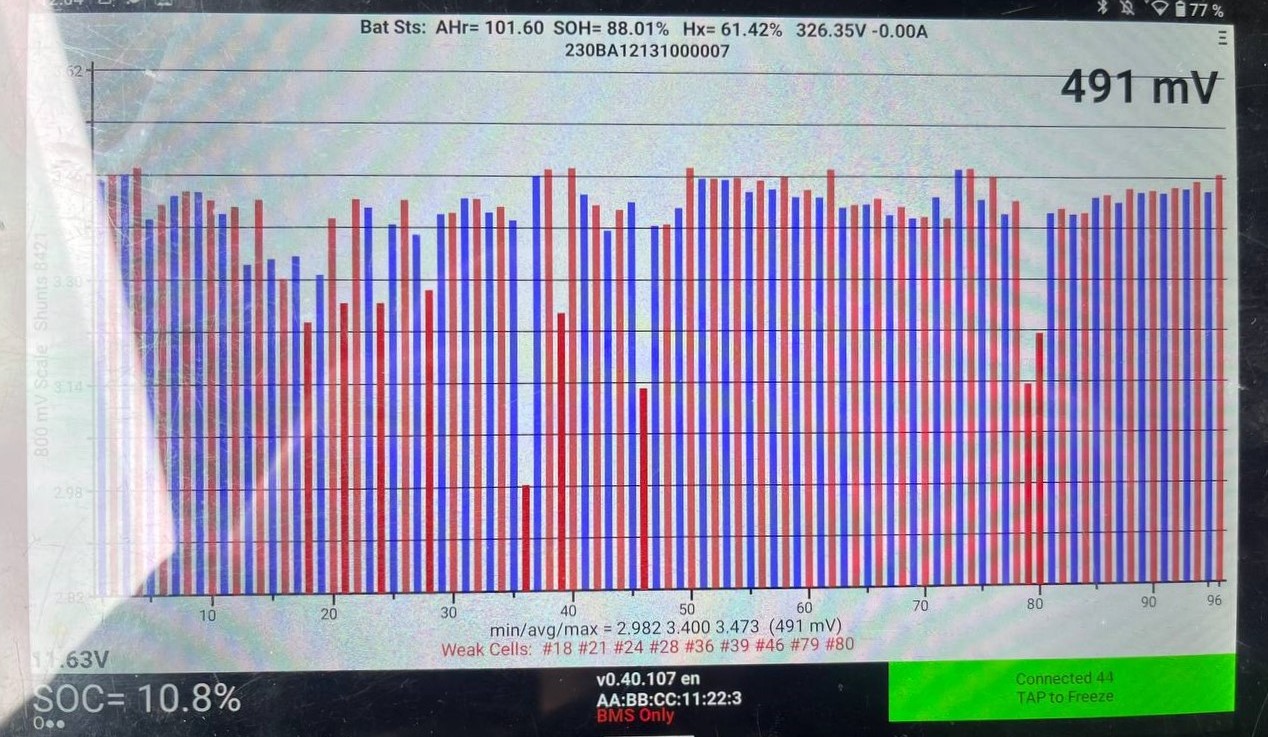

In fact, although the MS801 stand manufactured by our own brand MSG Equipment, which is used by our workshop, allows each module to be measured and charged separately, this would take a long time – there are 96 cells in a high-voltage battery, which would take several days. Therefore, we first had to assemble the BMS for testing. The test results showed that there were problems in modules 1, 38, and 76.

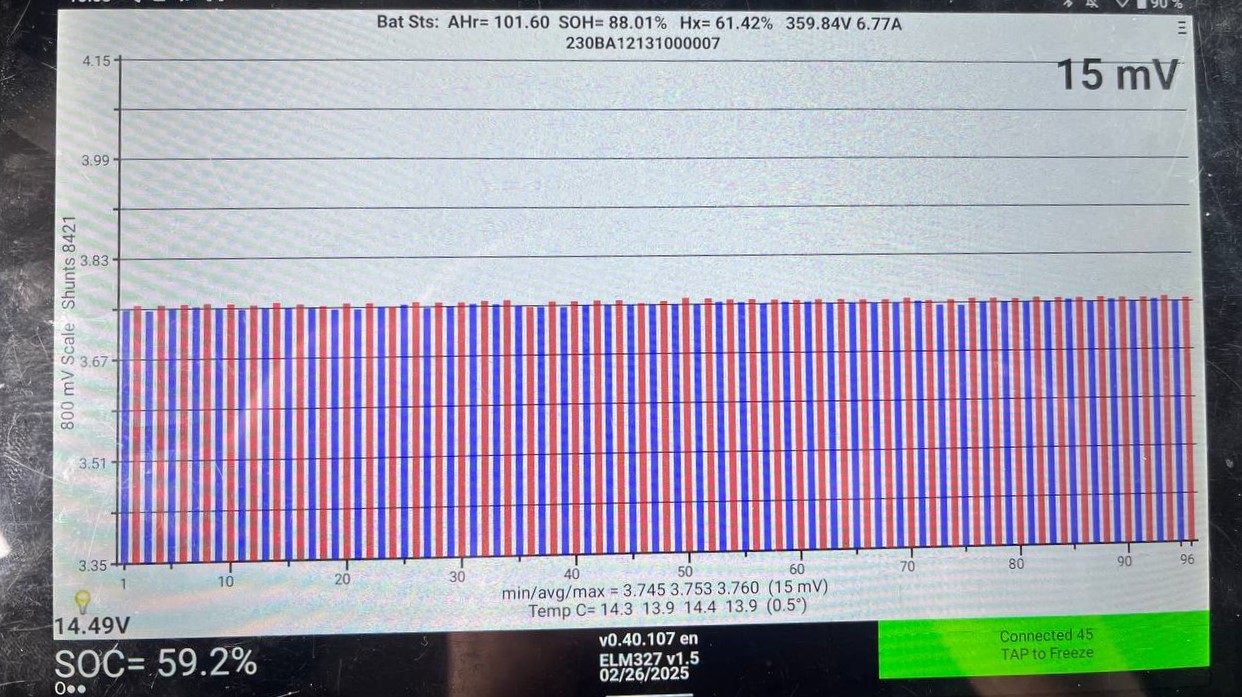

We replaced these three cells and rebalanced the battery. As a result, the difference between the modules was only 15 mV, which is an excellent result. After that, we installed the battery in the car and tested it under load.

However, during the load test, defects were found in three other modules: numbers 36, 46, and 80. At the same time, there were no complaints about the cells that were replaced during the first repair. We replaced three more modules, balanced the battery, and recharged it. No new problems were found, so the third car could also be returned to the customer—let them put it back on the road and deliver people's parcels.

Conclusion

As you can see, it makes no difference to STS whether the vehicle in front of us is a passenger car or a truck, privately owned or belonging to a large company. Any vehicle with any malfunction will be professionally repaired quickly and efficiently.