Rehabilitation of low-voltage Li-Ion batteries in hybrid vehicles

BMW X5

MERCEDES-BENZ GLE

AUDI A6

Hybrids are a class of cars that are something between «full» electric cars and classic cars with internal combustion engines. Therefore, the operation and repair of hybrid autos are partly similar to one or the other type. However, there are nuances that manifest themselves only in hybrids, or predominantly in hybrids. For example, problems with low-voltage batteries.

Hybrids are not the only ones.

Usually in our portfolio we give examples of repair of cars of a particular model. This time we will summarise the cases into one topic: repairing low-voltage lithium-ion batteries in hybrid cars. We have been approached by the owners of several of these vehicles with such problems

- BMW X5 (G05)

- Audi A6 C8

- Mercedes-Benz GLE-Class (W167)

The nature of the problems in all cases was approximately the same: the battery was completely discharged, but the electronics did not allow it to charge from the on-board system. The thing is, as soon as the charge level drops below normal, the BMS gives a signal to a relay that disconnects the battery circuit to avoid possible problems with lithium-ion batteries: overheating and even fire.

The manufacturer does not provide for the possibility of restoring this kind of battery, it must only be replaced. However, the cost in relation to this battery is very high. Even for a small, weighing less than 5 kg 12-volt battery LG for BMW, used, the price starts from 500 euros. However, it can be repaired by STS specialists.

This way we not only save our customers money, but also contribute to the environment, as people have not yet learnt how to recycle lithium from used batteries.

How to repair an LG 12V low-voltage battery from a BMW X5 Hybrid (G05)

First, let's talk about how low voltage batteries usually fail. Mostly it happens either due to prolonged parking, when the battery slowly loses charge and can't recover it, or due to carelessness - due to lighting, multimedia and third-party equipment plugged into the cigarette lighter socket when the engine is not running. While the engine is not running, charging of the low-voltage battery from the mains is blocked so as not to discharge the traction battery. Afterwards, there may not be enough charge.

Now, we've removed the battery from the BMW, it's a Korean LG Chem Li-Ion 10Ah 132Wh, and the voltage is 13.2V. Proof that the manufacturer considers it disposable is the non-disassembling case. Inside is its own BMS (Battery Management System), which has already de-energised the battery terminals - when connected to them, the voltmeter reads almost zero.

The battery's voltage is almost zero.

To open the circuit and deactivate the relay, we need to open the case. Carefully do it with a mini electric hacksaw, manually open the contacts and charge each battery in turn with an external device, constantly monitoring the charge level and temperature. Charged the battery, connected the relay, the voltage at the terminals is 13.32 volts. Waited to see if the system would shut down, checked the voltage again, assembled the case. The battery is ready to be installed in the car.

Repair of 48V Audi and Mercedes-Benz Li-Ion batteries

The next two batteries are the current sources in «soft» hybrids. Although often referred to as «starter» batteries, they drive the MHEV system's starter-generator and also power several other powerful consumers (such as the climate system and coolant pump). And «cold» starters and other 12 V consumers are powered by a different battery.

And the cold» starters and other 12 V consumers are powered by a different battery.

It is worth noting that, in addition to the causes characteristic of 12-volt lithium batteries, in mild-hybrid cars the cause of discharge of 48-volt batteries can be a malfunction of the starter-generator or loss of communication with it. In addition, the battery can shut down if it recognises a serious road accident.

The battery can also shut down if it recognises a serious road accident.

An unskilled intervention can also lead to blocked charging: opening and changing parameters. In this case, the converter or BMS units can record a fatal error and replace a serviceable and expensive unit.

.

But while here too the BMS blocks the ability to charge Li-Ion batteries, disassembling such batteries is easier. They don't need to be cut and then glued together, the case, the standard fixing is provided.

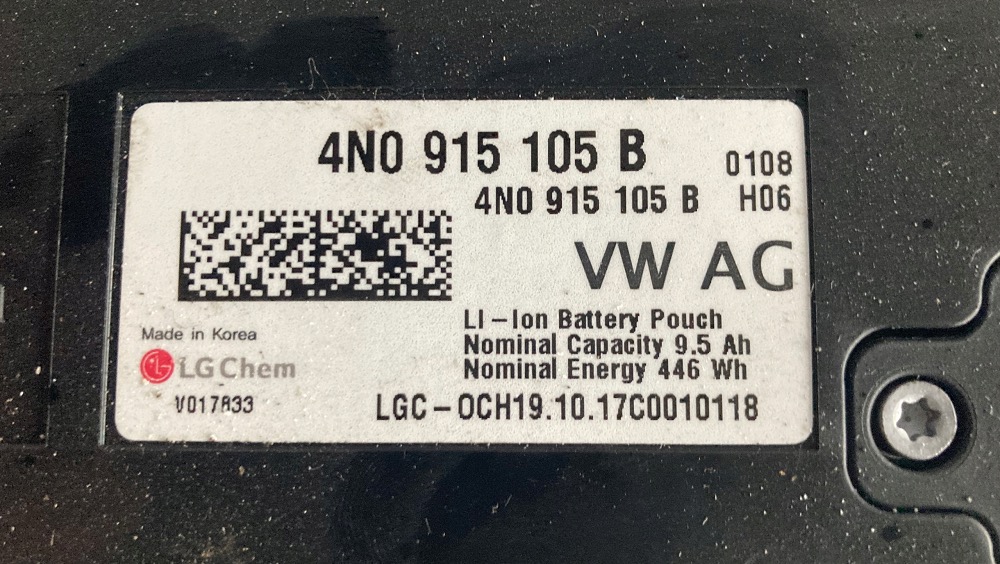

The first 9.5Ah battery used in Audi cars is made by the same LG Chem company, so the charging process is similar to the previous one: an external device and constant monitoring. At the end, the battery must be reprogrammed and fitted to the car.

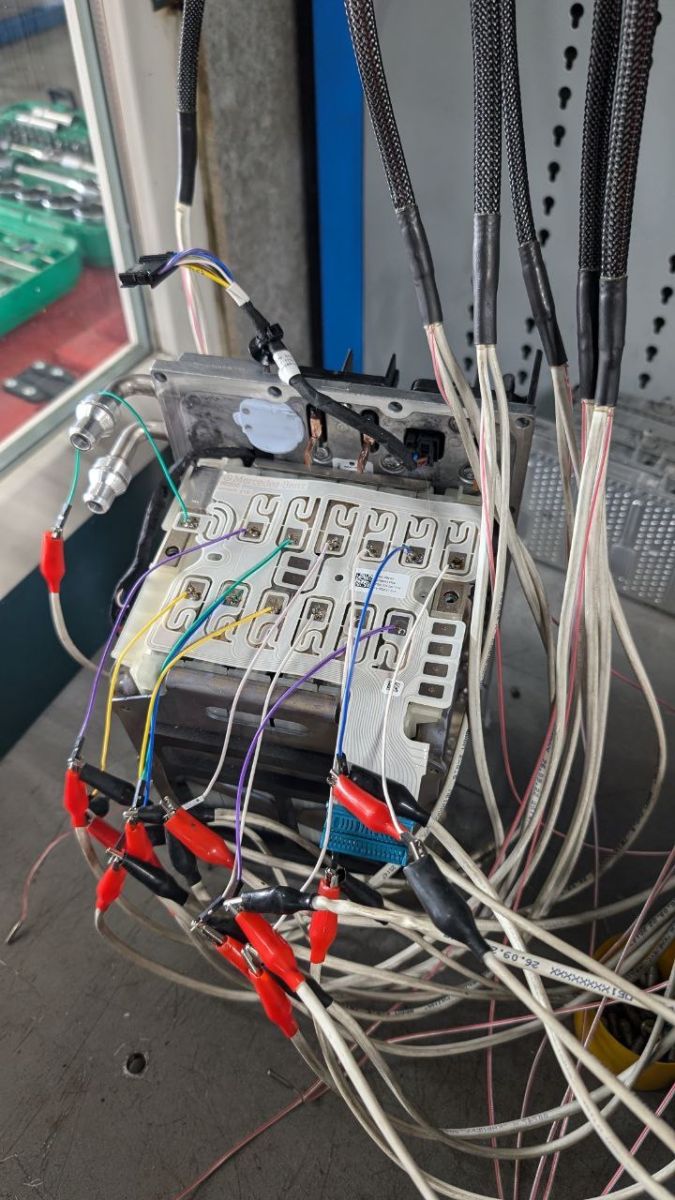

And the situation with the Mercedes-Benz battery is a bit more interesting. Here we were able to use not only the experience of STS employees, but also equipment of our own design. This battery is housed in an aluminium case, which is also easily disassembled, with a step-down converter - a DCDC block - installed at the top. Underneath are twelve batteries, each with 4V.

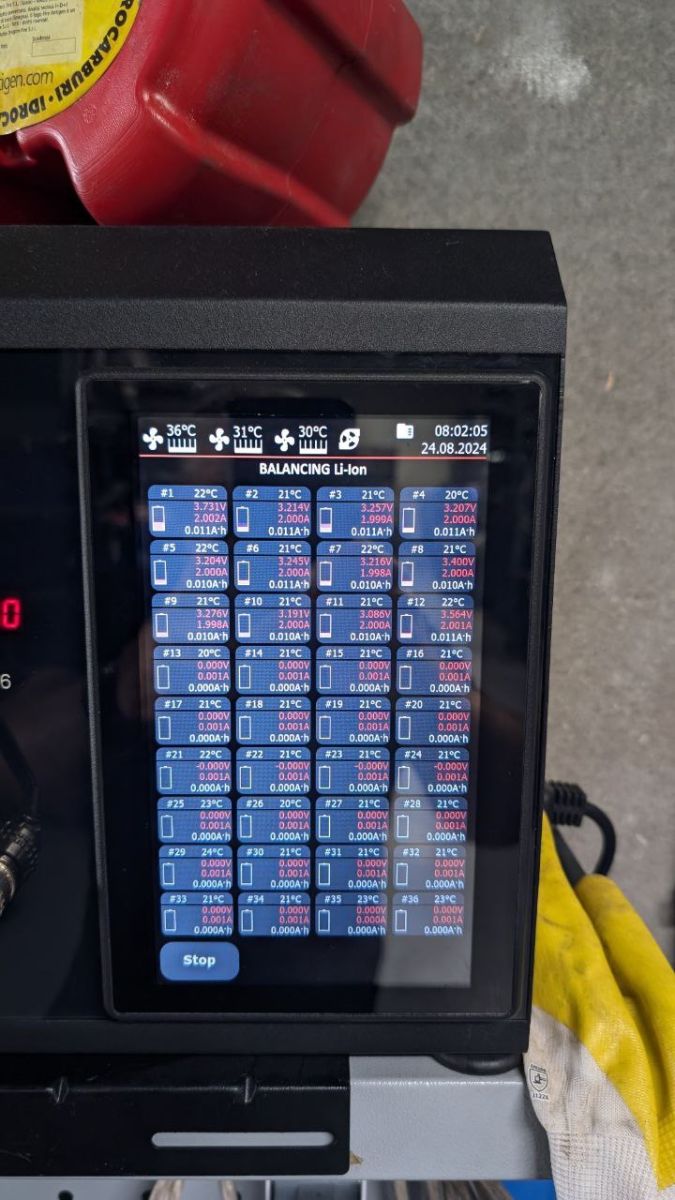

Soldering small wires to their terminals, we connected the cells to the MS800 stand, designed specifically for servicing and reconditioning Li-Ion batteries. This equipment can simultaneously work with 36 cells: charge, discharge and balance. In addition, it has temperature sensors that shut down the channel in the event of overheating, so it's very safe to use.

As in the previous cases, the battery has been fully charged and installed on the car. There should be no problems with it.

So, full discharge of low voltage hybrid batteries is not a judgement call, but just a reason to get to know the STS team of skilled technicians. We'll take a day to do any of the above work, and it'll certainly cost far less than a new battery.