Repair of DC/DC converter on Land Rover

LAND ROVER Range Rover

A typical problem with MHEV hybrids

The MHEV (mild hybrid) segment has been one of the fastest growing in Europe for several years. Such cars are actively entering the Polish market, both as new vehicles and as imports from EU countries. This is especially true for Land Rover and Range Rover brands, where 48V architecture has become standard for many diesel and gasoline versions.

In these cars, the DC/DC converter is a key link between two electrical configurations:

- 48V circuit (starter-generator, MHEV power electronics)

- classic 12V network (control units, lighting, safety and comfort systems).

This module is responsible for the stable power supply of all the car's electronics. Its failure often leads to a “chain reaction” of errors: malfunctions in control units, unstable voltage in the 12V network, messages about hybrid system malfunctions, and partial or complete loss of MHEV functionality.

Often, neither owners nor service specialists suspect problems with the DC/DC converter. Due to the similarity of symptoms—hybrid system errors, electronics malfunctions, and limited auxiliary functions—the starter-generator is most often suspected. In some hybrids, this is one of the most expensive components, so owners often agree to replace it, spending a lot of money. However, when such a replacement does not solve the problem, internal malfunctions of the DC/DC converter cause drops or instability in the 12V power supply, disrupting the energy exchange between the circuits, and the system continues to record errors even after installing a new starter-generator. As a result, the owner incurs additional costs without actually eliminating the malfunction.

The problem is exacerbated by the fact that most services in Poland and the EU do not perform component repairs of such modules, but only work according to the scheme of replacing assemblies. Given the high cost of DC/DC converters for Land Rover, this makes even a single malfunction financially very significant for the owner.

That is why accurate diagnostics of 48V systems, understanding the relationship between the starter-generator and the DC/DC module, and the ability to repair them are critically important — this is where the difference between a regular service center and a specialized workshop becomes fundamental.

Case study: Repair of a Land Rover 48V/12V DC/DC converter – description of the malfunction, diagnostics, and repair

Stage 1. Initial diagnostics on the vehicle

The Land Rover came to us with a completely inactive MHEV system. The car exhibited a number of related symptoms:

- periodic hybrid system error messages

- unstable electronics operation

- problems with the 12V power supply.

Since the car had already been diagnosed at another service center with a focus on the starter-generator (K8D2-11a240-AC), STS specialists performed a complete check of the entire 48V/12V circuit to rule out false identification of the faulty unit.

After computer diagnostics, it was determined that the source of the malfunction was the 48V/12V DC/DC converter (K8D2-14B227-AM). To confirm the hypothesis, the module was removed from the car and sent to the STS electronics workshop.

Important: in addition to those listed, Land Rover DC/DC converters may also have the following part numbers:

- N8B2-14B227-AD

- N8B2-14B227-AA

- L8B2-14B227-AB

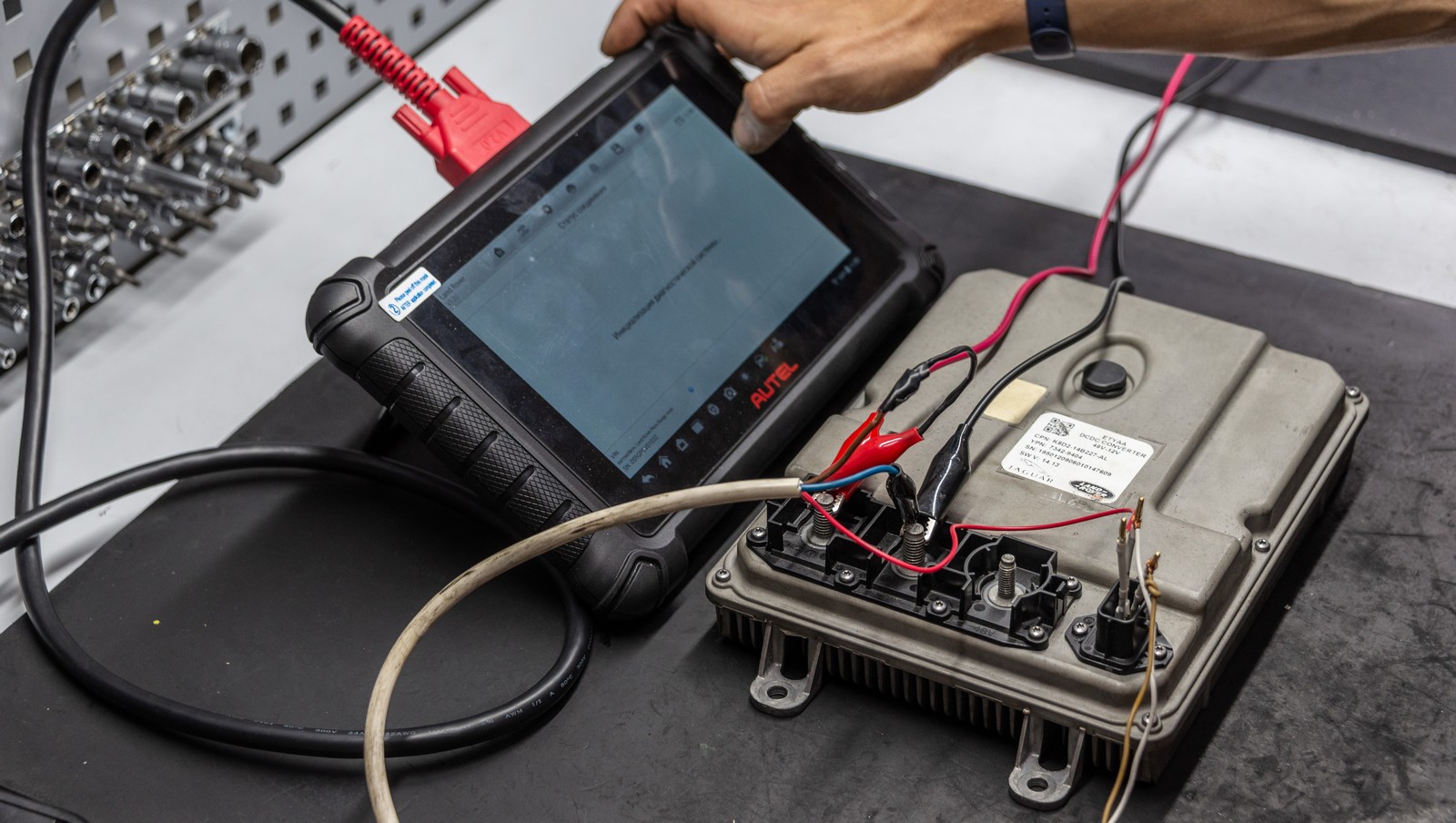

At the stand, the module was powered from a laboratory source and errors were read from the internal memory. The following characteristic codes were recorded:

- P0A94-49 – reduced efficiency or internal malfunction of the DC/DC converter (often associated with overheating or failure of the power section);

- P0D33-11 – excessive current in the output circuit, indicating overload or internal short circuit;

- U3008-13 – problems with the power supply or “ground” of the control module.

This data directly indicated that the module was no longer able to correctly provide energy exchange between the 48V and 12V circuits.

Stage 2. Disassembly and technical inspection

DC/DC converters of this type are sealed modules with a combined design:

- power section (switches, drivers, filter elements)

- control electronics

- measurement and protection systems.

After carefully opening the case, STS specialists diagnosed the boards using measuring and soldering equipment for working with power electronics. During the inspection, damaged radio elements were found in the power section of the board, which caused unstable operation of the converter and overload errors.

Such defects are not always visually apparent and often require in-depth electronic diagnostics, experience with power modules, and an understanding of the topology of a specific DC/DC node.

Stage 3. Electronics restoration

After locating the problem areas, the boards were dismantled for repair. Damaged elements were removed and replaced with components that meet the original specifications for electrical and thermal parameters.

Components for such units are not mass-produced and are not sold as standard “auto parts” — these are power electronics components supplied from European and global markets. STS has established supply channels and its own experience in selecting analogues compatible with specific modules.

After replacement, the following was performed:

- checking the integrity of tracks and connections

- checking resistance and the absence of short circuits

- analyzing signal stability in key circuits.

Stage 4. Assembly and bench testing

The refurbished module was assembled and connected to a test bench. The converter was tested in various modes, simulating operation under loads close to real-world driving conditions.

The following were monitored:

- voltage conversion stability

- response to load changes

- absence of repeated errors in internal memory.

After successfully completing the bench tests, the module was reinstalled in the vehicle and the entire system was re-diagnosed.

Stage 5. Result

After installation in the vehicle, the MHEV system resumed full operation. There were no errors in the electronic units, the 12V power supply stabilized, and the DC/DC converter performed its function correctly. The Land Rover owner received a fully functional unit without the need for an expensive replacement assembly, which significantly reduced the cost of repairs.

Conclusion

This case clearly shows that in modern hybrid systems, the problem is not always obvious. The symptoms of a DC/DC converter malfunction may look like a starter-generator failure, causing the car to undergo expensive but misguided repairs. As a result, replacing complex components does not eliminate the root cause, and the owner incurs additional costs without actually solving the problem.

The practice of STS in Warsaw is based precisely on finding the root cause of the malfunction, rather than replacing components based on symptoms. Component repair of DC/DC converters, in-depth electronic diagnostics, and mandatory bench testing allow complex modules to be restored where other services see only the option of expensive replacement. It is this approach that ensures a technically correct result and real savings for the car owner.