Repair of Karma Revero 2018 in STS.Electro - restoration of the battery and charging module

Karma Revero

Unique masters deserve unique cars! This time, our STS.Electro workshop welcomed a true legend – the 2018 Karma Revero. It is a sports hybrid saloon, the successor to the iconic Fisker Karma, which surprised the world with its innovative approach back in 2008. Interestingly, the first Fiskers appeared even before Tesla began sales.

A bit of history

Henrik Fisker, the designer and founder of the company, bet on unusual architecture:

- two electric motors on the rear axle;

- a 20 kWh high-voltage battery;

- a GM Ecotec petrol turbo engine;

- solar panels on the roof.

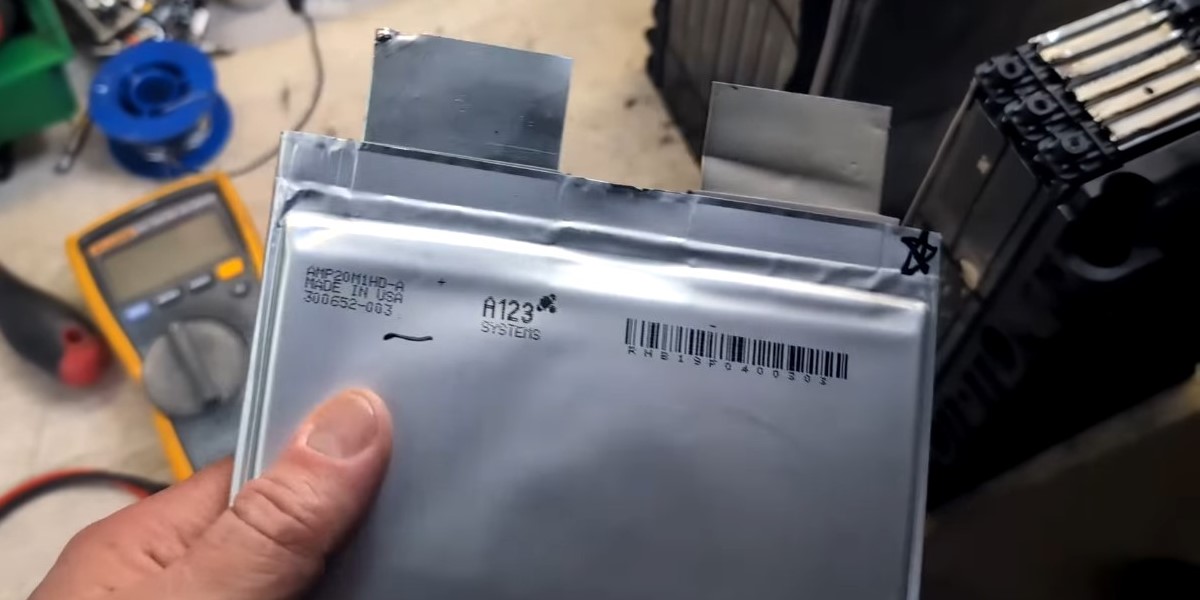

This gave the car a futuristic look and offered cutting-edge solutions. However, battery problems proved fatal: A123 Systems, the battery supplier, went bankrupt after several recalls, and production stopped in 2012. Subsequently, the Chinese corporation Wanxiang bought the assets, and in 2016, the project was revived under the Karma Automotive brand. Thus, the world received the updated Karma Revero.

Case study of the repair of a 2018 Karma Revero at STS.Electro

The Revero was brought to us on a tow truck. The car's behaviour was as follows:

- after removing/installing the terminal from the 12V battery, the car started, went into ‘Ready’ mode, but did not drive;

- The internal combustion engine started, ran for a few minutes, a sharp smell of petrol came from the exhaust, and then the engine died;

- It was only possible to restart the car after disconnecting the battery again;

- The battery charge on the display showed 11% all the time;

- The battery did not receive power from the charger;

- The car had not been driven for about eight months.

In addition, we noticed a non-functioning touchscreen and strange noises in the speakers.

Initial diagnosis

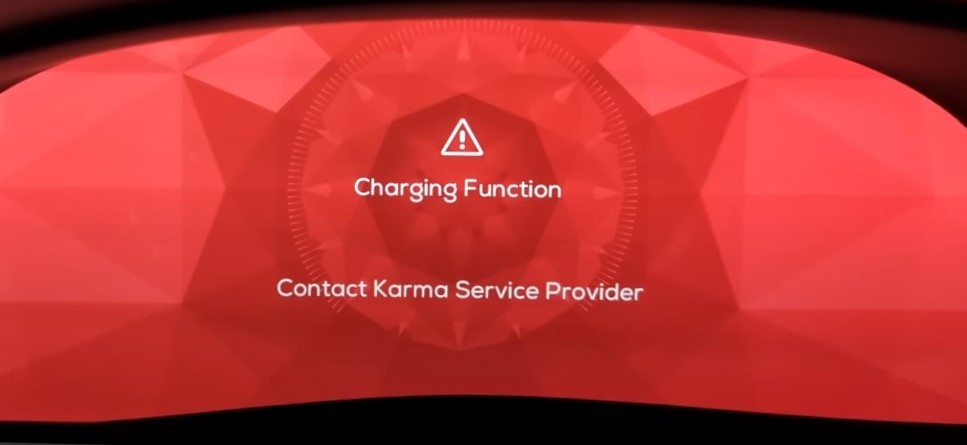

We connected the charging gun – the system recognised it, but immediately displayed the message: ‘Contact your Karma provider’. In other words, charging did not take place.

The scanner showed a number of critical errors:

- connection to the drive motor control module lost;

- hybrid transmission and battery control module errors;

- low voltage in the ignition circuit;

- request to turn on the malfunction indicator.

The difficulty was that the original Karma software is not available, so diagnostics are only possible through GM production units similar to those found on the Chevrolet Volt.

Working with the battery

The errors indicated problems with measuring the voltage in the cells. So the next step was to remove the high-voltage battery. It is installed in the central tunnel at the bottom of the body, so the car was lifted on a hoist.

After disassembly, we found that the battery still contained A123 Systems components. Externally, it looked high-quality: cooling radiators, compact modules. But testing revealed a serious problem – one module was ‘dead’, with a voltage of only 0.24 V instead of 3.2 V. Inside, there was oxidation and traces of leakage.

Battery repair

We removed the faulty module, ordered new elements and replaced them. Next:

- we secured the modules with the original tape;

- we applied thermal pads;

- we assembled the battery;

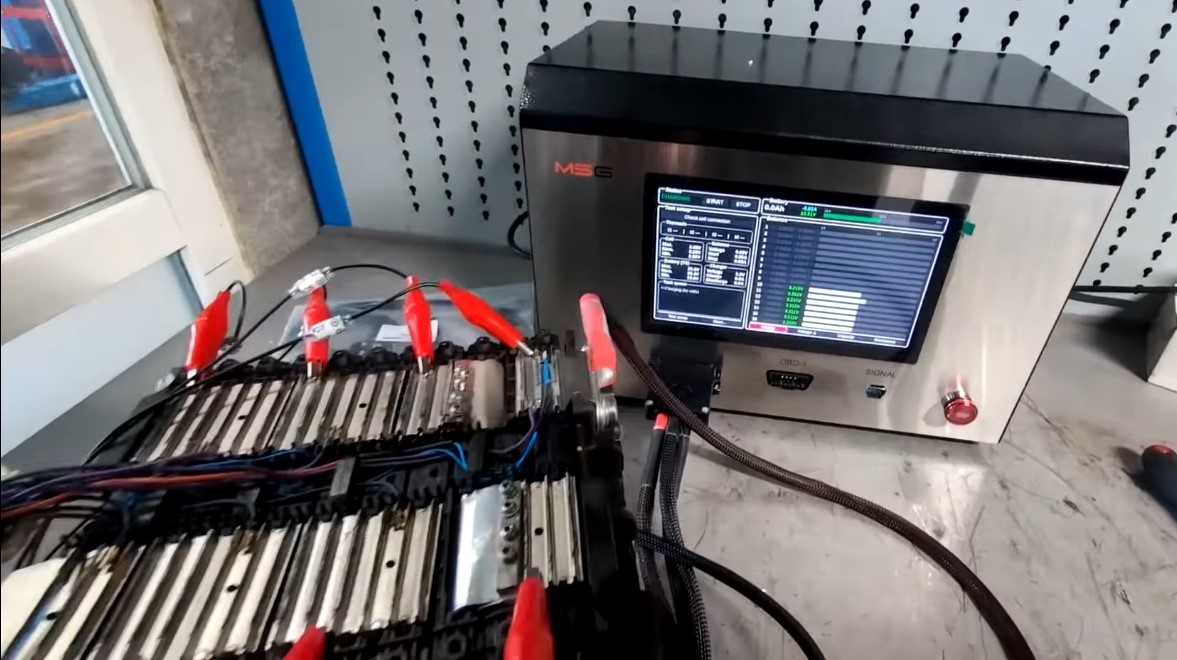

- charged and balanced it on the MS 801 stand (more modern than the MS 800, with the ability to charge with up to 60 A), manufactured by our own brand MSG.

It was this equipment that allowed us to quickly and efficiently restore the battery's performance. According to our technicians, the cause of the failure was a manufacturing defect: during the welding of the casing, scale could have fallen off, causing microdamage and subsequent leakage.

Second stage of repair: charger

We ordered new components, and when they arrived, we started assembling the battery.

After installing the battery, the car started and drove off. Even the recuperation was working, but charging from the mains still had not been restored. An additional check revealed a problem with the charger connectors. Because the unit is located very low and has virtually no protection, it was damaged by moisture and mechanical impact.

Unfortunately, the original charger cannot be repaired, and the Chevrolet Volt analogue is not suitable – Karma uses a CAN bus, while Volt works with an analogue signal.

We solved the problem in a different way: we printed a new connector on a 3D printer. The first version made of filament proved to be unreliable, but the second, made of resin, withstood installation and became a full-fledged replacement.

The result of the Karma repair

After completing all procedures, our hybrid car:

- starts without any problems;

- runs in normal mode;

- charges both from recuperation and from a charging station.

There are still some minor issues with the multimedia and audio system, but that's another story.

Conclusion

The repair of the Karma Revero showed two things at once:

- Even rare and complex cars with high-voltage battery problems can be repaired if approached systematically.

- Our technicians are able to find solutions even when original parts or software are not available.

STS.Electro in Warsaw is a place where cars get a second life. And Karma Revero is a vivid confirmation of this.