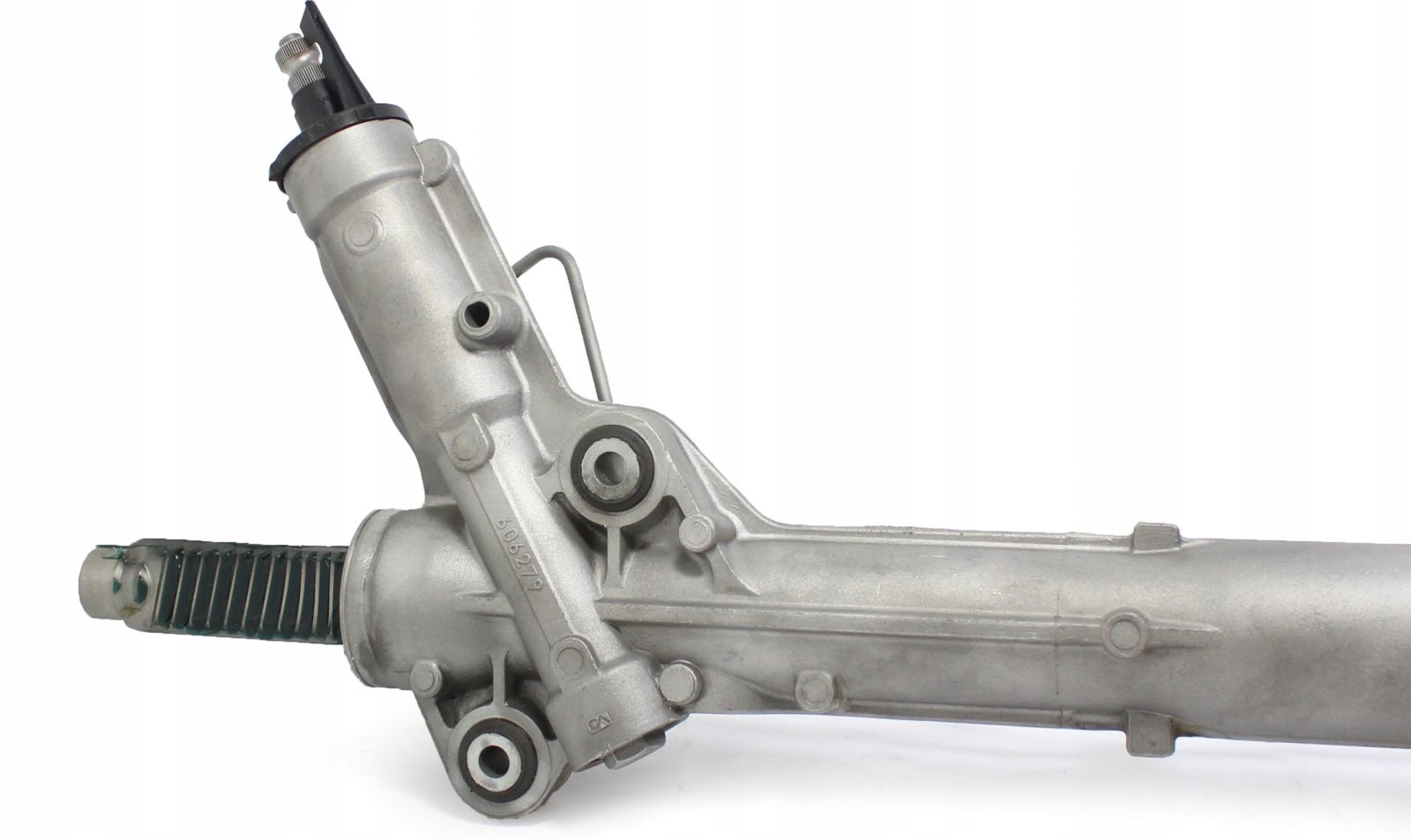

Features of Mercedes Sprinter 906 Mercedes Sprinter 906 steering rack repair

It is no secret that not only passenger cars, but also commercial vehicles need repairs. Moreover, vehicles that transport cargo and people need a more responsible approach and frequent maintenance. Especially since trucks and buses have much higher mileages than cars at the same age. These vehicles also have typical faults – for Mercedes Sprinter W906 it is, for example, breakdowns of the hydraulic steering rack. This vehicle can be repaired reliably and reliably at STS, which has many years of experience in rebuilding steering systems of all types.

Sprinter 906 steering rack faults

Mercedes-Benz W906 — the second generation of the popular German truck Mercedes-Benz Sprinter. Sales started in 2006 in parallel with another best-seller in this class Volkswagen Crafter, and not for nothing: the cars are unified in many ways, including similar steering mechanisms. So all the information below will be relevant for Crafter as well.

The steering rack of these cars was developed for commercial vehicles, taking into account the heavy loads (payload of Sprinter in maximum configurations reaches 5.5 tonnes) and intensive operation. However, due to the conditions in which the vehicles have to work, the unit requires regular maintenance, the use of quality hydraulic fluid and timely replacement of worn parts.

This car uses power steering driven by the pulley of the internal combustion engine (without electric drive), so the problems associated with the steering rack are similar to those that occur in the hydraulic systems of other cars. As there is no electronic control unit that can transmit steering faults, the driver will recognise breakdowns by symptoms such as:

The steering rack is not equipped with an electronic control unit that can transmit steering faults.

- red oil stains under the car;

- disappearance of force on the steering wheel when the engine is not warmed up (or vice versa when it is very warmed up);

- steering wheel play in the centre position;

- knock and vibration in the steering wheel on uneven roads;

- jamming and crunching in the steering rack;

- darkening of the operating fluid in the power steering reservoir;

- permanent decrease of its level;

Faults are also typical for other power steering rack. They can be grouped into the following groups:

- Fluid leakage associated with the violation of tightness of seals (rod and distributor glands).

- Corrosion of the stem.

- Corrosion of gear teeth.

- Wear in the seating areas of glands and bearings.

- Distributor bearing failure.

- Ring development (wear) on the distributor housing.

- Wear and tear on the rack components: torsion, spool, pinion.

- Mechanical damage to components: steering rack housing, rod, torsion.

How we rebuild power steering racks

StS Steering rack repair follows the following algorithm:

- Primary diagnosis of the malfunction. Specialists determine the symptoms and causes of breakdowns.

- Dismantling. The rack is disconnected from the steering column, hydraulic line and all fasteners and transferred to the repair shop.

- Disassembly. All internal components of the steering rack are removed from the housing: the rod, distributor, dust covers and sealing rings, bearings, bushings, glands, etc. Check the condition of the gears, worm pair and gear part of the rack for wear or damage.

- Deciding on the nature of the repair. In case the restoration of the steering rack is recognised as inexpedient, the client is offered two options: installation of a brand new unit, or a steering rack from the exchange fund, fully restored by us on our own equipment in compliance with all technologies.

- Restoration of the steering rack using new parts. If the main elements are subject to restoration, a set of repair works is carried out. It may include: grinding the rod, bushing seating holes of the body of the steering rack, replacement of other elements – bearings, glands, bushings, seals.

- Assembly and inspection of the steering rack. At the end of the repair of the rack necessarily check on the stand, simulating the modes of operation of the car. Under pressure are checked indicators of steering torque gain, as well as tightness of seals.

- Installation of the rack on the car and test drive. The final stage – complete assembly of the car and driving tests. It is necessary to know that the removal and installation of the steering rack involves the procedure for setting the angles of the wheels – camber.

Special features of repair of racks with «triangular» rod

Steering rack repair Mercedes-Benz Sprinter 906 is not fundamentally very different from the repair of similar units of other cars, but has some peculiarities. They are conditioned by the design of the node: it has the so-called «triangular» stem. At the edges it is round, as in other cars, but its toothed part, entering into meshing with the gear of the steering shaft, has a ribbed shape with three angles. Racks of this configuration are used on other Mercedes-Benz models (such as the GL-Class X164) and some other vehicles.

Drivers don't notice the differences in this design when operating, but when repairing, the difference is very significant. The outer gland with a sleeve on such rails can be changed without special problems. But to replace the internal seals it is necessary to cut the piston on the rod, otherwise it will not be possible to install new oil seals. In this case, the piston must be installed new, and it is very important not to confuse the direction of installation. Incorrect installation will not only damage the new piston (which is pressed onto the rod), but also risk tearing the oil seals.

These, as well as other nuances, can only fully know the experts who are professionally engaged in service and repair of steering racks. Such as the qualified staff of the company STS. Our customers are always confident that they will receive a repaired steering rack, which is not inferior to the factory part, but at a much lower price. We are fully confident in the quality of all components, so we give a six-month warranty on the unit itself, as well as all components and work performed.