Everything About Rotary Pairs in Hydraulic Power Steering Pumps

Rotary pair, working pair of the hydraulic power steering pump, rotor and stator pair - there are many names, but the principle of operation is one. It is the heart of the pump that generates pressure and ensures the continuous circulation of oil in the hydraulic power steering system.

Main Technical Data of the Rotary Pair

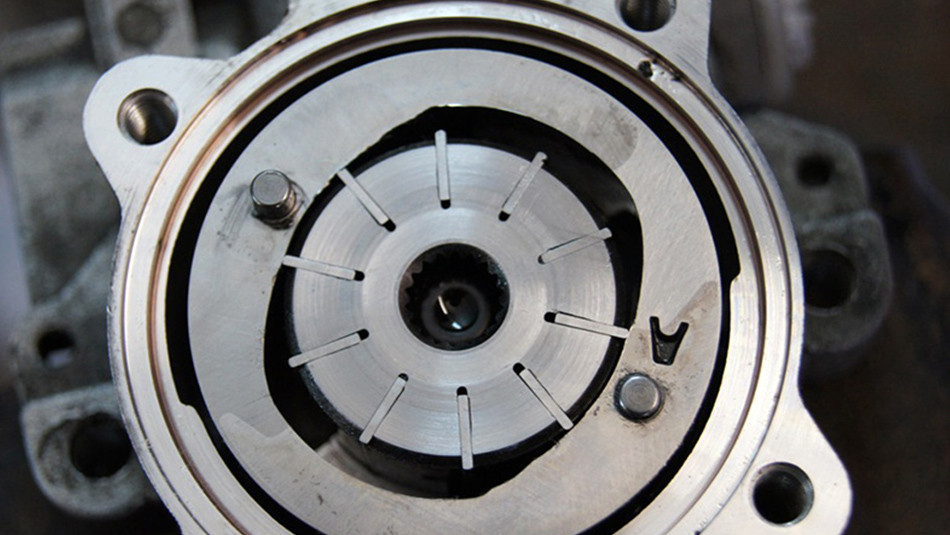

The rotary pair of the hydraulic power steering pump is located inside the device's housing and consists of three elements – the stator, rotor, and blades.

Stator: It is the stationary outer part of the rotary pair, which, along with oil inlet plates and seals, ensures the pump's tightness. In most cases, the stator is elliptical in shape - this way, the rotor is relieved under the influence of pressure forces, meaning it wears out more slowly.

Blades: They create low and high-pressure areas and ensure the flow of oil from one area to another.

The rotational speed of the rotor depends on the rotational speed of the internal combustion engine or its own electric motor (if the pump is electrically driven).

The operation of the rotary pair can be described in three stages:

- After starting the engine, oil from the tank is supplied to the pump through hoses. The oil enters the rotary pair through the openings of the distributor disks.

- During the rotation, the blades, under the action of centrifugal force, are pushed out of the grooves and press against the stator walls, then move back. The extended plates create a low-pressure area in this part of the stator where oil is drawn in through the distributor disk channels.

- When the plates approach the narrowing part of the stator, they move, the pressure increases, and oil is pushed into the pressure fitting and enters the steering rack distributor.

Now, let's move from technical functions to malfunctions and their causes.

What Breaks Down in Rotary Pairs and Why?

The rotary pair consists solely of metal parts. It may seem that they should quickly be destroyed due to continuous friction. However, the oil circulating in the system lubricates the working parts of the hydraulic power steering pump, and the design of the assembly removes additional loads from the rotor.

It is logical that most rotary pair malfunctions are directly related to the quantity and quality of hydraulic fluid: old and dirty oil is the main enemy of the hydraulic power steering system. In other cases, the working pair simply "wears out" because even metal is not eternal.

If something cracks or fails under the hood, and the steering wheel is stiff, most likely, the rotary pair is sending SOS signals – you will have to dismantle the pump and check.

Main Rotary Pair Failures:

- Blades Are Worn: If you carefully monitor the quality and quantity of oil, and the plates are worn out at the end, it means your pump is too old. The worn-out blades do not touch the stator walls, meaning they do not create low-pressure areas.

- Rotor Grooves Are Worn: This is also a problem of old devices.

- Wear of Blades and Grooves: Wear and tear are a natural process, and only parts can be replaced.

- Defects on the Inner Wall of the Stator or Outer Wall of the Rotor: This happens if old oil circulates in the system with small solid particles or metal chips. In this case, the fluid, which should prolong the life of the rotary pair, destroys it faster. As a result, micro-cavities appear between the rotor plates and the stator walls, and the pump does not generate the desired pressure. This problem is solved in a service setting - the master grinds the stator walls. How do metal chips get into the oil? Micro-metal particles appear in the system if the pump worked without oil for some time, and metal parts began to crumble. Moreover, metal chips "knock out" the sealing rings of the distributor.

- Burrs on the Blades or in the Grooves: The causes, consequences, and ways to solve this problem are the same as in the previous point.

- This leads to untimely replacement of the hydraulic power steering fluid

- Clogged Rotor Blades: The reason is impurities in the oil or old, sticky hydraulic power steering fluid that clogs the grooves and prevents the blades from moving freely. The blades extend/retract unevenly, and the required pressure is not generated. This problem can be solved by dismantling the working pair, cleaning the grooves and blades. Flushing the hydraulic power steering system and filling it with new oil is necessary.

Very rarely does it happen that the rotary pair is physically broken. This usually occurs due to the faulty operation of other pump components, such as the shaft, support bearings, pulley, or belt. Due to the improper functioning of these parts, the rotary pair is damaged, starting to knock, loosen, and, in some cases, the rotor may even crack.

Rotary Pair Can Be Repaired

Most pumps are dismantled, and most rotary pairs can be repaired. This means that any part of the hydraulic power steering pump's working pair can be repaired – the cost is much lower than the total replacement of the assembly.

But! It will be effective only with slight wear or faults in the elements. If, for example, metal chips have already dug grooves on the stator walls, there is no point in grinding it – you will have to buy a new one. This means that the longer the damaged rotary pair operates, the more difficult it will be to repair the elements.

Remember - the sooner you contact the service, the greater the chances of solving the problem through repair. If you notice heaviness in the steering wheel, noise, whistling, knocking, or grinding during pump operation, immediately contact the nearest specialized auto service – perhaps the rotary pair of the pump can still be saved.