Remanufactured Spare Parts: A Good Purchase or a Bad Idea?

Many car owners in Poland are familiar with the concept of remanufacturing used parts, yet doubts persist about the viability of this procedure. Lack of trust stems from insufficient information, a situation quite different from that of Europeans who readily opt for remanufactured spare parts, especially during car repairs. Let's take a closer look.

An analysis of the total number of spare parts dismantled from cars during the repair process reveals that only 20% of components are entirely unsuitable for further use. The remaining parts can either be used under certain conditions or remanufactured.

Two crucial facts should be noted:

- Approximately 85% of spare parts, with wear on the surface up to 0.3 mm, can fully restore their performance.

- The percentage of regenerated external and internal cylindrical surfaces is around 54%, threaded surfaces 12%, toothed surfaces 11%, keyways 8%, flat surfaces 7%, and all other surfaces 8%.

Modern remanufacturing methods for assemblies and spare parts conserve resources, requiring five times fewer technological processes and saving 70% of the metal used compared to new part production.

Do these numbers not make an impression?

Why Aren't Remanufactured Spare Parts Popular in Poland?

Firstly, the quality of applied technologies is not always optimal, and the associated labor costs are high. Therefore, many manufacturers prefer to buy a Chinese alternative, which costs less than a regenerated assembly, even if it serves for a shorter period.

The second reason is manufacturers engaging in deception. Under the guise of a factory-regenerated spare part, they sometimes provide a simply repaired component, which is not the same.

The third reason is the negative stance of car manufacturers who aim to discourage the use of regenerated spare parts to avoid losing profits from selling new parts.

However, in many European countries, car owners take advantage of "Exchange" services, offering the replacement of a worn assembly with a regenerated one for a small additional fee.

From an economic and convenience perspective, this is an excellent option, minimizing the downtime of the vehicle compared to repairs. Additionally, individuals receive a regenerated original spare part with a warranty and minimal extra cost.

International Marking of Regenerated Spare Parts

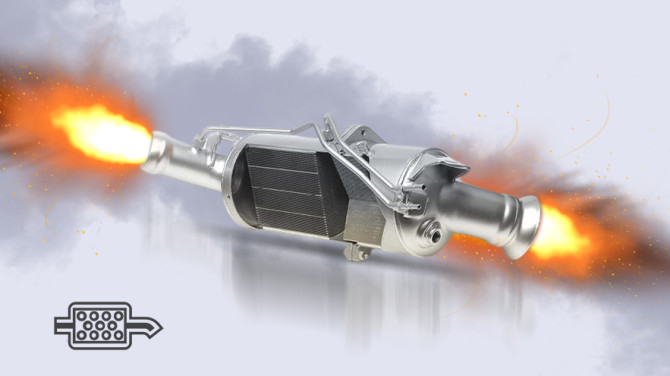

Remanufactured: Assemblies regenerated by factory manufacturers. Only the housing, free of mechanical damage, undergoes reuse. After cleaning and polishing, new "filling" is inserted, and the assembly is placed in the original packaging with assembly instructions.

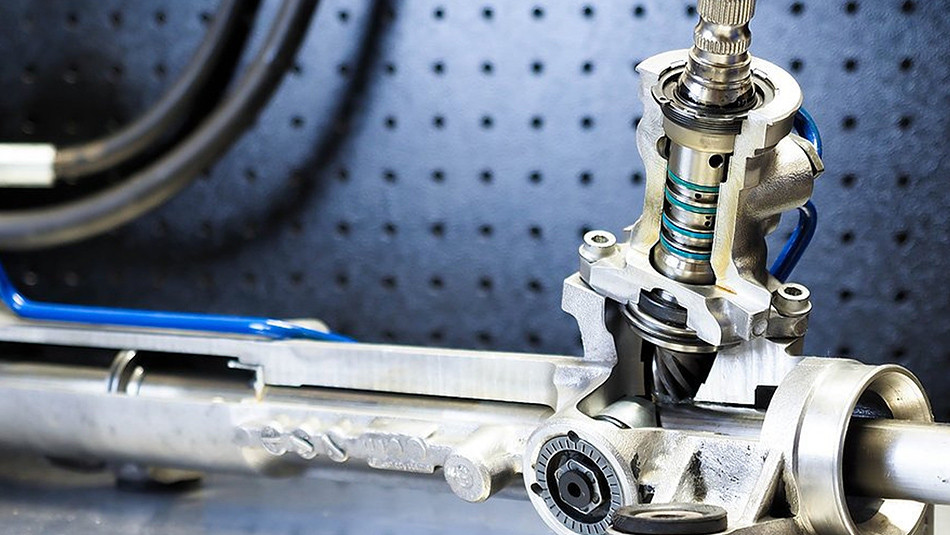

Rebuilt: The most common method for regenerating complex and expensive vehicle mechanisms. The assembly is disassembled, the housing is cleaned of deposits and rust using sandblasting, then thoroughly washed. A protective coating is applied chemically. Only non-worn nodes and the housing are reused, while the remaining components are replaced with new ones. After assembly, the unit undergoes testing on a diagnostic stand and is then placed in the original packaging with instructions and a warranty card.

Reconditioned: This process is less complex, requiring lower-tech equipment. The housing of the repaired assembly is manually cleaned with a wire brush, degreased, and painted silver, even in areas where paint is not strictly necessary. Instead of damaged parts, new, non-original replacement parts are used. Seals, sealing rings, bearings, brushes, bushings, and other quickly wearing elements are also replaced. Typically sold without instructions and original packaging, they are not tested on stands and come with a minimal warranty - usually one month.

Repaired: This method involves "reworking" the assembly and using repaired components from analogous units. In other words, two to three damaged mechanisms are taken, and one working unit is assembled. A written warranty cannot be guaranteed. Purchasing an assembly "guarantees" its performance only through the seller's verbal assurances.

Used: Used spare parts from dismantled cars with defects, often from wrecked vehicles. In this case, you are buying a "pig in a poke." If you're lucky, the part will work for a few months.

Shedding Light on Regenerated Assemblies Through Remanufactured and Rebuilt Schemes

Better to Buy a Chinese Replacement: Chinese goods can vary in quality. If you purchase a non-original spare part produced at a factory with well-known trademarks, you may save some money, neglecting the purchase of original spare parts. However, the cost of a regenerated original spare part equals the price of a new Chinese part of good quality. A cheap, unbranded counterfeit product may not only quickly fail during operation but also damage vital vehicle components.

Regenerated Assemblies are Inferior to New Ones: Concerns about the quality of regeneration in factory conditions are unfounded. Moreover, you will save significantly, as a new original spare part costs much more.

Repairing an Assembly Will Be Cheaper Than a Regenerated Spare Part: Perhaps this is true. However, it is unknown how responsibly workshop professionals approach their work and how long a repaired assembly will last. Additionally, more time will be spent on workshop services.

As seen, there are numerous advantages to buying regenerated assemblies. The key is to pay attention to the marking, verify the credibility of the seller, and consider the opinions of other buyers.

You can purchase regenerated spare parts on our website under the "MSG Rebuilding" trademark. These parts are regenerated according to the Rebuilt technology, confirmed with a warranty card, and packaged in the original packaging.