Replacement of Kia Niro EV and Hyundai Kona Electric engine and gearbox bearings

KIA Niro

HYUNDAI Kona

Replacement of Kia Niro EV and Hyundai Kona Electric engine and gearbox bearings

After repairing three identical cars with very similar malfunctions, it was possible to establish the cause and identify a typical problem for Korean electric vehicles.

Rumble while driving – who is to blame and what to do

Part 1. It could be a stub.

The first Kia Niro EV with a mileage of 77,000 km appeared at the service station. The client complained about a knock at the bottom – it was as if a gnome was sitting there with a hammer and hitting plastic with it. However, the dwarf did not always do this, mainly after an energetic ride. Then, the sound could disappear and reappear with a new sharp push on the pedal.

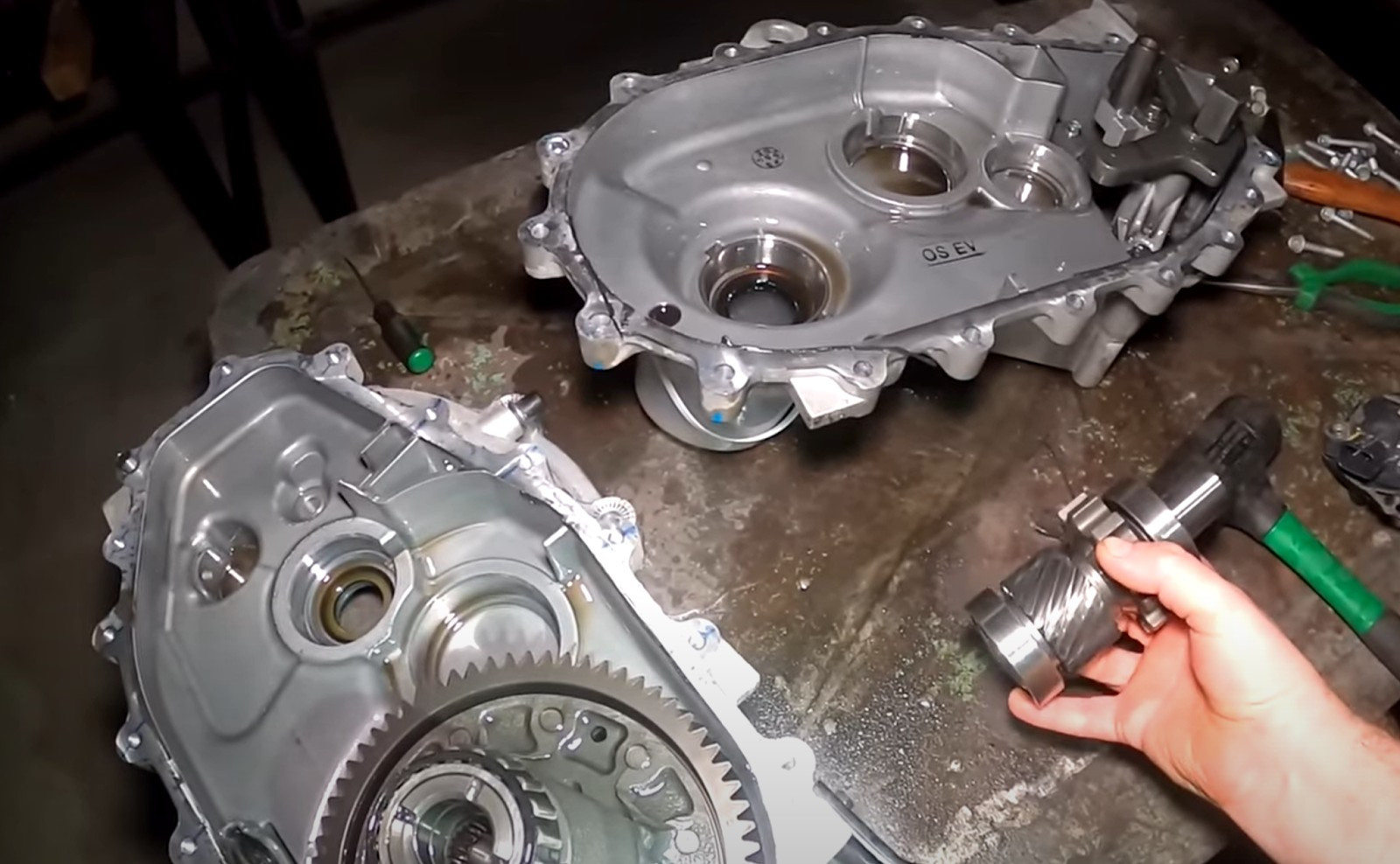

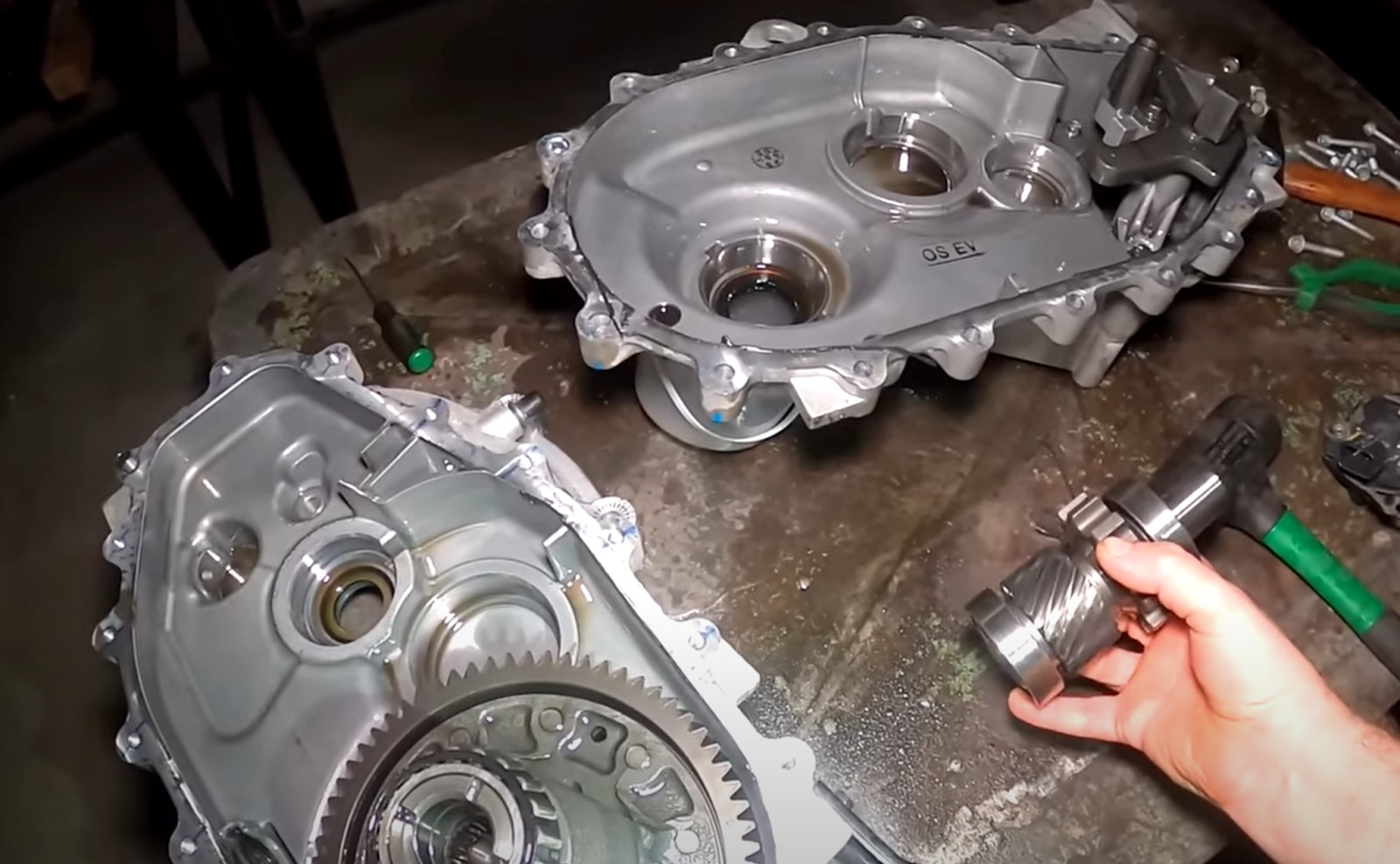

If it is normal for dwarves to be afraid of fast acceleration, then for electric cars – not so much. The knock came from the gearbox, so we started to disassemble it. The first surprise was the cap of the primary shaft, which fell right into your hands. The shaft itself under the hull had a working "walked". At the same time, the condition of the bearings did not cause any complaints: there were minor scratches, but there were no sinks or other critical moments.

The assumption about the cause of the failure was made as follows: it was a dropped plug. Meanwhile, the bearings were also changed ( everywhere, except for the differential – the necessary ones were not immediately available, and the client did not want to wait), fitted with special spacer rings, assembled the gearbox, and installed on the car. A test drive showed that the problem seems to have been resolved.

Part 2.No, it looks like chips.

Hyundai Kona Electric came second. The problem was similar, but it seemed much more serious. First, the Rumble did not disappear in any driving mode. Second, this Kona's mileage was quite small—just over 30,000 km.

They immediately disassembled the gearbox, but the plug did not fall out; it is in place. They replaced all the bearings, including the tapered ones on the differential, which were not available for the previous car, especially since this time they were scratched. We assembled the gearbox, conducted a test drive, and...

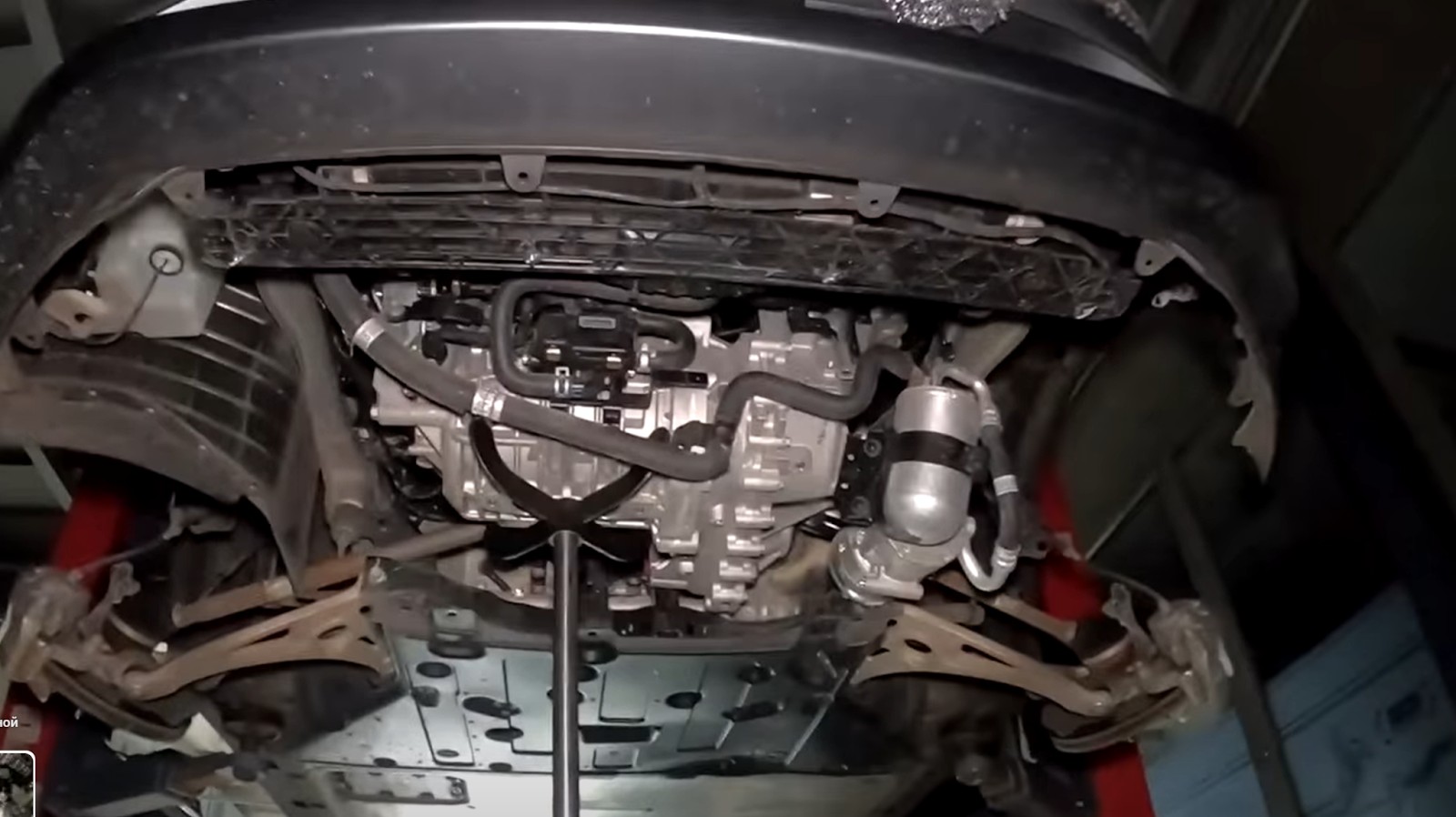

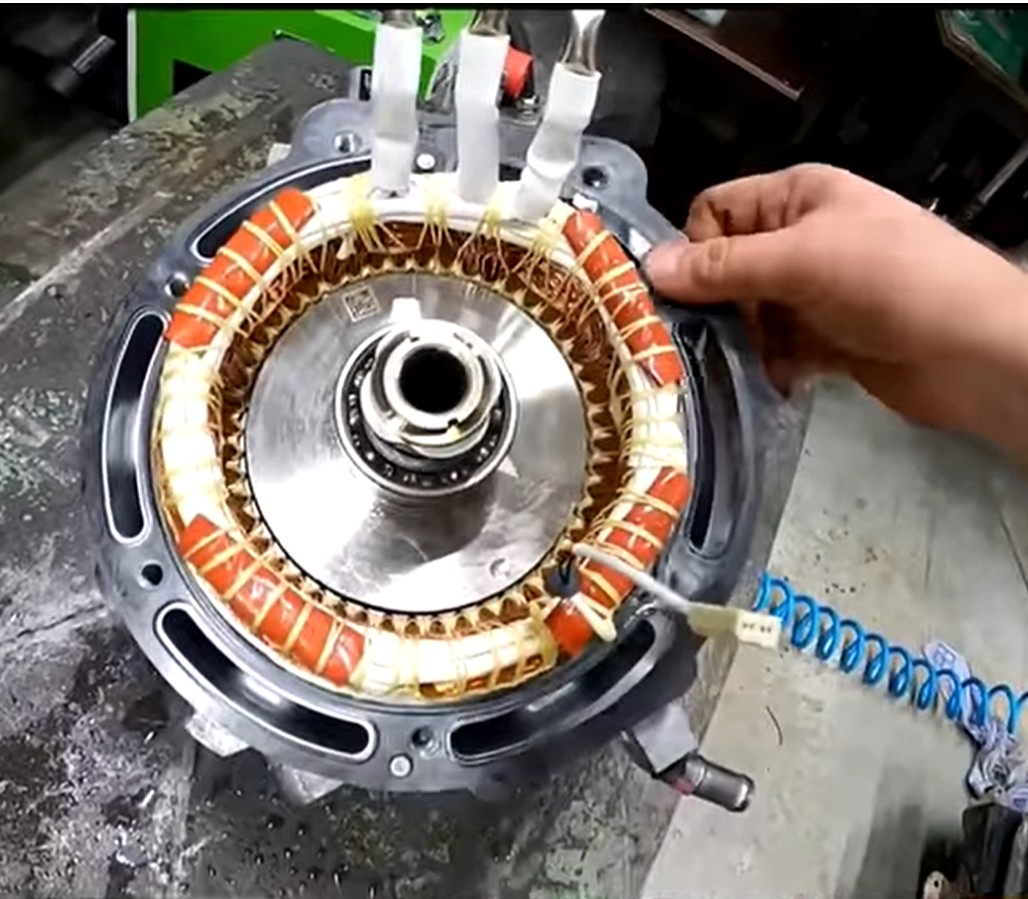

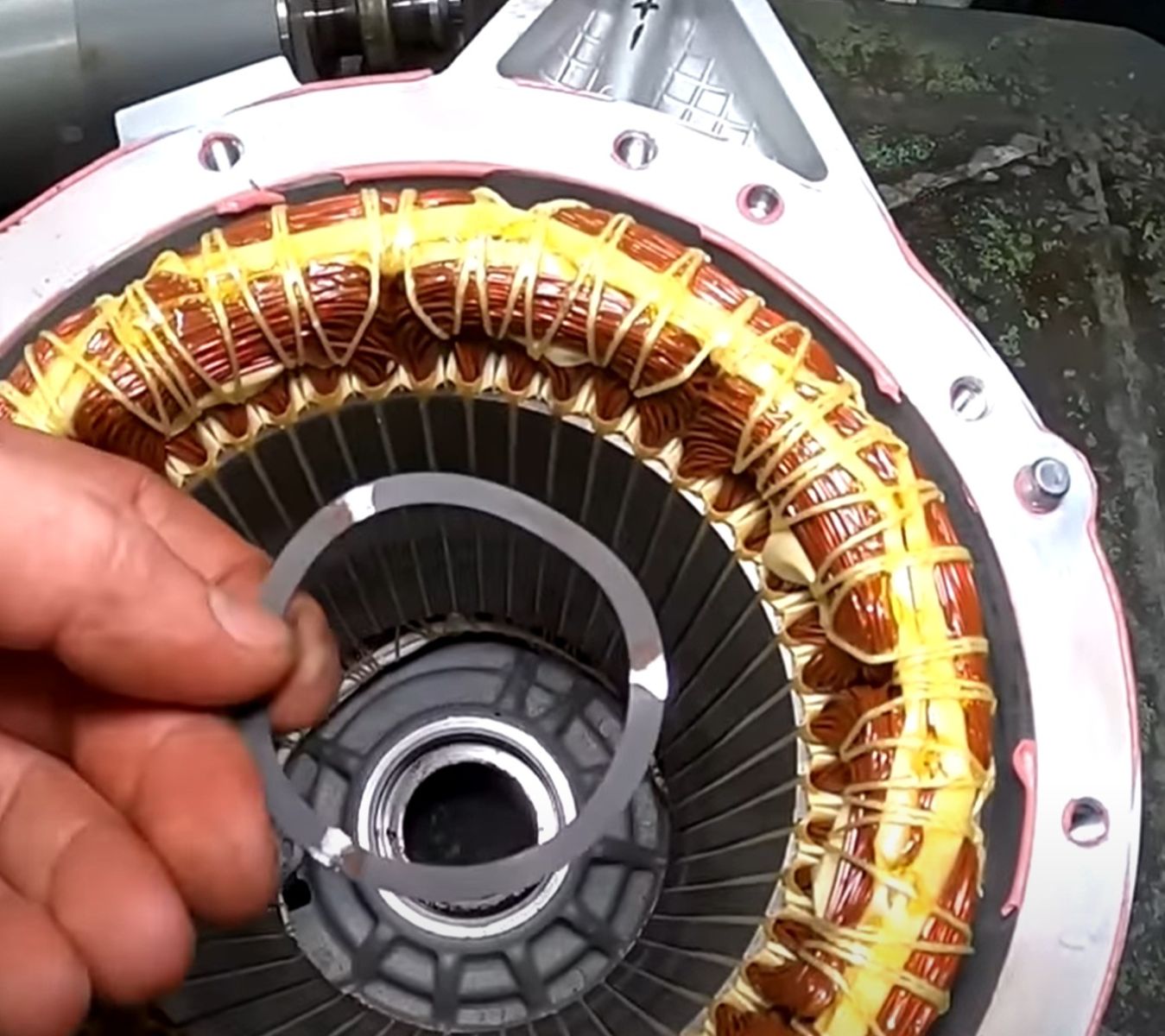

And they found that the noise became quieter, but did not disappear at all. If during the initial diagnosis the noise was clearly coming from the primary shaft, now it was heard from the other side, from under the cover. So, now you need to disassemble the engine itself. They decided to shoot it without a gearbox. This is also possible, especially since the node has already been sorted out.

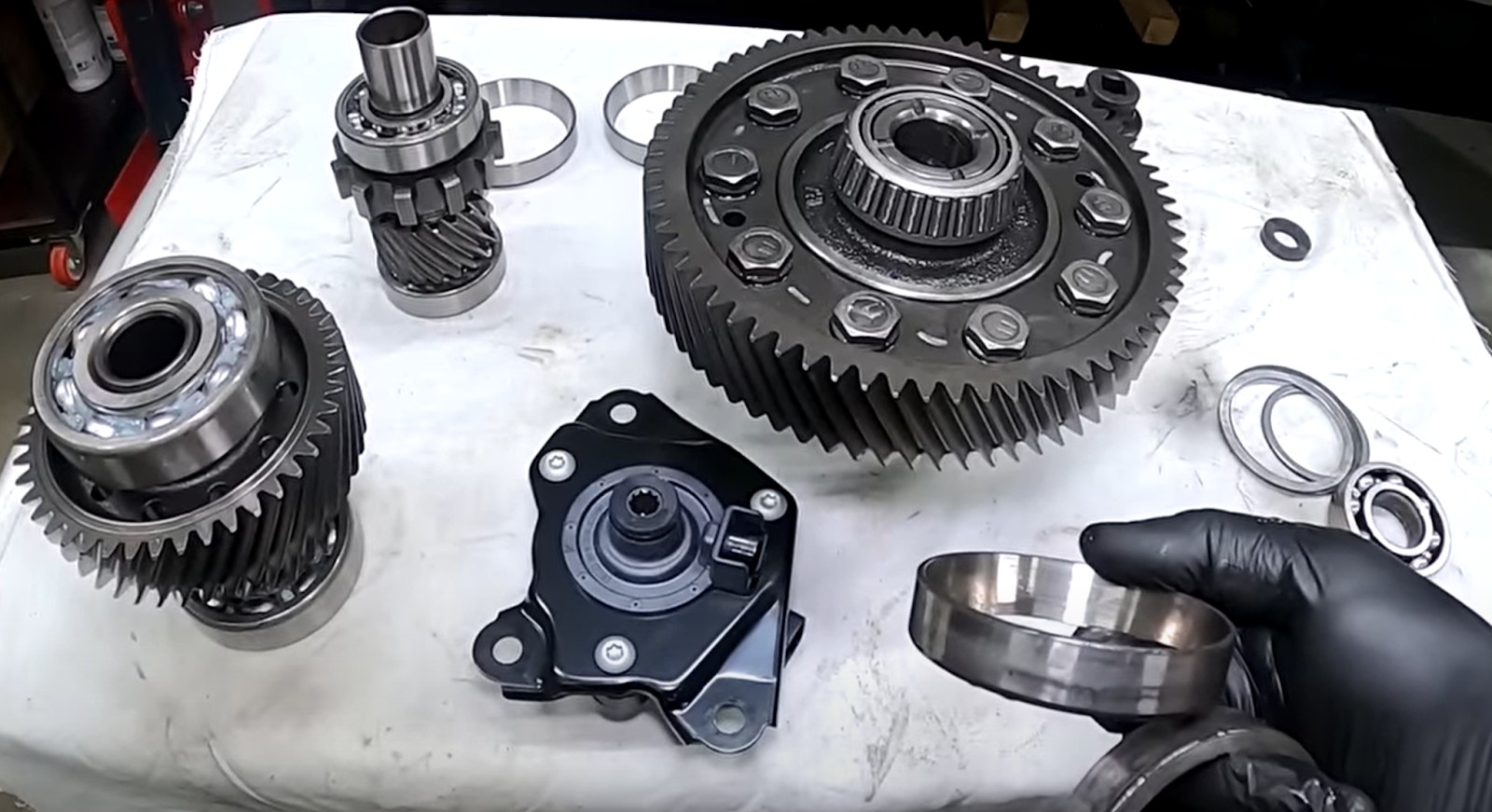

After disassembly, an interesting thing turned out: there is rust on the primary shaft bearing, but not because it is rusty. The fact is that the bearing here is made floating due to the fact that the iron rotor and aluminum motor housing have different coefficients of expansion, so a rigidly fixed bearing would necessarily wedge during heating. But the freewheel played another joke on him: the bearing began to rotate in its seat, making small shavings that turned into rusty dust.

This dust got inside the bearing through the oil seal, and although the rollers and clips, as well as the first time, remained completely intact, the Grease became dirty and too thick. Theoretically, such bearings can be reconfigured and re-installed, but it is better to change them. Which we did.

The engine was assembled and installed in place. The bearing, just in case, was additionally missed, so that if it wants to get loose again, it is no longer done on dry, but on lubrication. The car was assembled and driven. The sounds disappeared. So, is the chip problem? Maybe, but... Let's not rush it.

Part 3. final verdict.

The third car with a similar problem was again Kia Niro EV. Just as in the previous case with Kona Electric, the mileage was "children's" - 35,600 km. The characteristic noise – rumbling-was heard in all modes, especially clear at low speeds.

An autopsy of this engine did not show any rust, much less a fallen-out plug. Moreover, there is still grease on the seat of the primary shaft bearing. Even after examining its components with an electronic magnifying glass, no damage was found on the balls or clips. The only difference from the previous cases is that the most problematic, that is, the backlash, was not the gearbox bearing and not the front one in the engine, but the one that was closer to the transmission.

Otherwise, the picture coincided. After changing all the bearings, fitting them to the seats, we again achieved silence on the road.

Conclusions

On the one hand, it is impossible not to notice that the quality of Korean-made electric vehicles is steadily growing. Sometimes even quite funny things happen: in an effort to make their cars better, Kia/Hyundai, for example, does not spare the mounting material. The number of bolted connections in electric vehicles, for example, is much larger than in cars with internal combustion engines of the same manufacturer.

But, on the other hand, there are also frankly disastrous moments. And these are, in our opinion, bearings – at least in the gearbox and motor. Neither the diameter (which would be more suitable for attachments than for a power plant), nor, moreover, their quality does not correspond to the application. Perhaps the situation will change over time, but for now, unfortunately, we are confident that the handling of Hum and noise in Kia Niro EV and Hyundai Kona Electric electric vehicles will continue.