Electro-Hydraulic Power Steering (EHPS) System

Power steering is divided into hydraulic and electric power steering. However, there is also a hybrid - electric-hydraulic power steering. One might say, fire and flame in one device. What is the specificity of this type of power steering, and how to diagnose it correctly – that's what our article is about.

What is Electro-Hydraulic Power Steering (EHPS)?

If the operating principle of hydraulic and electric power steering is roughly clear, how does EHPS work, and what is it composed of?

Such power steering consists of:

- Electronic Parts (Control Unit)

- Power Supply Part (Electric Motor)

- Hydraulic Part (Gear Pump)

The operation of EHPS is similar to hydraulic power steering, but the driving force is not supplied from the internal combustion engine, but from an electric motor.

Since EHPS is both an electric and hydraulic amplifier, there is a double risk of failure: both electrical components (electric motor, control units) and hydraulics (pump) can malfunction.

How is the Diagnosis of EHPS Conducted?

If the driver arrives complaining about a stiff steering wheel but does not know exactly what type of power steering is in the car, the automotive mechanic must figure it out. He visually checks the car (on the lift), determines what type of power steering is in the specific vehicle.

The mechanic determines that EHPS is in front of him. Then, he checks if there is fluid in the system, i.e., oil. It happens that power steering simply turns off because there is no oil. The master checks the expansion tank.

Fact. There are tanks that are separate from the pump and tanks that are mounted with the pump - their peculiarity is that they are not very convenient: for example, in the fenders or behind the engine. It is difficult to access such a tank without disassembling it.

If the oil level is normal, the automotive mechanic checks whether power is supplied to the amplifier when it is still in the car, without disassembly. It can be visually checked whether all connectors are connected, whether all wires are connected to the pump, whether they are intact. If a torque sensor is installed in the car, the mechanic checks if it is connected. If everything is fine, he moves on to the next stage.

EHPS Pump

He checks if the fuse on the pump is blown. There is a safety block that is also separate from the pump and only relates to power steering; such a fuse can be located in a common block. If something is wrong with this fuse, an automotive electrician deals with its diagnosis and repair.

And if the automotive mechanic sees that the electrical system is okay, he removes the pump from the car. After disassembling, the pump is washed and cleaned. After cleaning, the pump goes to the workshop.

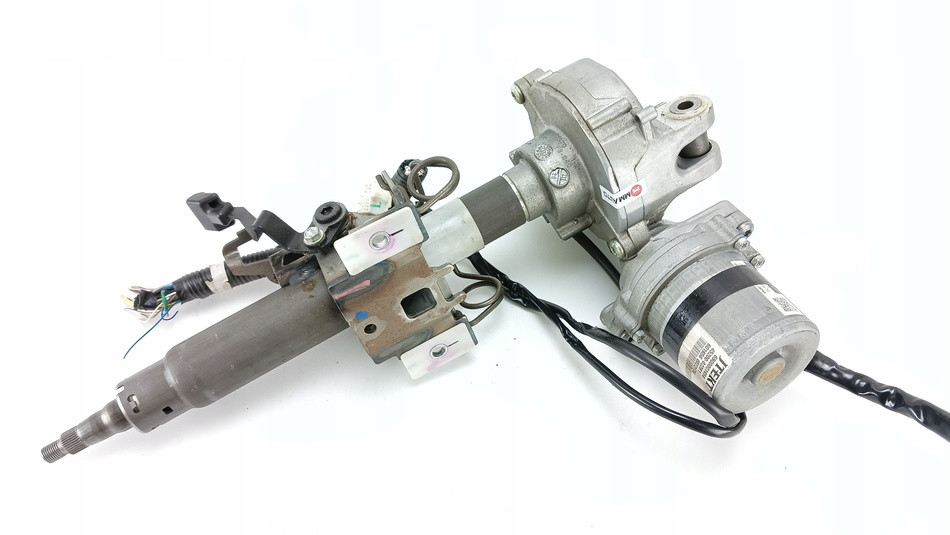

Fact. The pump usually consists of 2-3 parts; the structure resembles a layered cake: the first lower part is the electric motor, the second part is hydraulic (pumping), the third is electric (control unit), and the top is the tank.

In the workshop, the pump is started on the diagnostic stand during disassembly. The auto electrician connects the pump, supplies power (to check all wires). If the pump still does not respond, the mechanic proceeds to disassemble the pump into its components.

During disassembly, it becomes clear precisely what is not working in the pump. He prepares an estimate for repair and announces the diagnostic result, price, and repair time to the car owner.

And then? If the price and time are right for the customer, the mechanics repair the power steering pump.