What is a repair kit and how to choose one for your steering rack

The steering rack is an important part of a car's steering system, responsible for transferring force from the steering wheel to the wheels. During operation, this part is subjected to significant loads, which can lead to wear and malfunction. A steering rack repair kit is often used to fix problems. In this article, we will look at what it is, what components it consists of, and how to choose the right one.

When is a repair kit needed?

A repair kit, or repair kit for short, is a set of parts needed to repair a specific unit or assembly. Its purpose is usually to restore functionality and performance – to eliminate play, knocking, misalignment, or fluid leaks. It is usually a set of plastic, metal, and rubber parts used for minor or partial repairs during maintenance.

A repair kit is needed in cases of steering rack malfunction, such as:

- Fluid leakage – if oil stains appear under the car in the area of the rack;

- Steering play – with increased play and a noticeable loss of steering precision;

- Extraneous noises – knocking or grinding when turning the steering wheel may indicate wear of the rack parts;

- Heavy steering – if increased effort is required to turn the steering wheel while driving;

- Wear of dust covers – damage or rupture of dust covers can lead to dirt and moisture entering the mechanism.

It should be noted that not all faults can be repaired with a steering rack repair kit. In complex cases, such as tooth wear or corrosion, the damaged shaft or rod will also have to be replaced.

Types of steering rack repair kits

The composition and contents of the kit primarily depend on the type and model of the rack that needs to be repaired. Repair kits can be divided into four groups:

- Kits for mechanical racks;

- Kits for units with hydraulic boosters.

- Spare parts for gearboxes with and without hydraulic boosters.

- Repair kits for power steering pumps.

The simplest kit is for repairing a rack without a booster. It consists only of rubber rings and a support bushing (steering rack silent block).

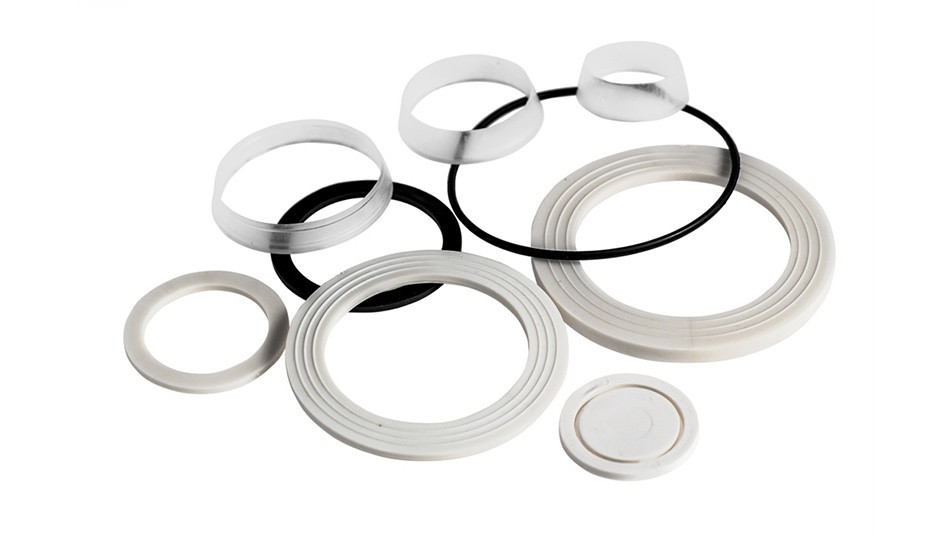

A standard repair kit for a steering rack with power steering contains the following parts:

- two high-pressure power seals that withstand the oil pressure in the system;

- support bushings that hold the steering shaft (usually plastic);

- rubber rings on the shaft bushing;

- Teflon rings that are installed on the piston;

- bearings (included in the extended version).

A repair kit for a power steering gearbox usually includes:

- a set of balls for the worm gear;

- seals;

- Teflon rings;

- rubber rings;

- gaskets.

The steering power steering pump kit contains:

- seals;

- gaskets;

- rubber rings;

- a bushing.

Additional elements are often added to the repair kit, the necessity of which is determined by the specific features of a particular car model. For example, in the steering rack of Mercedes-Benz Sprinter 2-t, 3-t and 4-t cars (2000-2006 model years), two types of spools are available: wide or narrow. Therefore, a comprehensive repair kit for the steering rack of these cars contains sets of Teflon and rubber rings for each type of spool. Meanwhile, the repair kit for Nissan Almera II and Primera (2003-2017) contains only one set of 5 Teflon rings – four for the distributor and one for the hydraulic cylinder piston.

Most often, repair kits include housing bushings (for example, in the repair kit for the electric power steering), additional Teflon and rubber rings for the bushings, side pressure pistons and bypass tubes, foil inserts, washers for the side pressure pistons, dust seals, and other components.

Purpose of steering mechanism repair kit components

Now that we know what repair kits are for, let's take a look at what each part in the kit is responsible for.

Rack seals are the main rubber sealing parts that seal the rack components. There are two types of seals: standard and heavy-duty.

The first type is responsible for sealing the joints of rotating or moving parts, preventing oil, grease, or other fluids from leaking, and protecting components from dust and dirt.

The second type, power seals, are special seals used in conditions of high loads, pressure, temperature, or aggressive environments. They differ from standard seals in their reinforced design and durability. In the manufacture of these products, additional stiffening ribs or reinforcement, a reinforced metal frame, double or triple sealing edges, as well as special materials such as fluororubber, polyurethane or special composites are used.

The main causes of seal wear are:

- Natural wear – rubber or polymer materials lose their elasticity over time under the influence of temperatures and lubricants.

- Dirt and dust – particles getting inside cause abrasive wear of the sealing edge.

- Mechanical damage – incorrect installation, impacts or misalignment during installation can damage the seal before it is even put into operation.

- Exposure to aggressive liquids – poor quality or unsuitable lubricants can corrode the rubber or polymers of the seal.

- High pressure in the system – if the system operates at a higher pressure than the seal is designed for, it may deform or even “push out” of its seat.

- Worn shafts and seats – if the shaft or housing where the seal is installed is worn or damaged, the seal will not be tight and lubricant will start to leak.

Rack support bushing – a part that supports the rod and prevents the rack shaft from moving. Support bushings come in different types – bronze (often used on power steering systems), steel, plastic, and rubber.

The most common causes of bushing failure are:

- mechanical wear;

- incorrect repair.

Steering rack bearings (ball bearings) ensure the axial rotation of the distributor shaft. Bearings, like seals, wear out mechanically.

Rubber rings create a tight seal between the rack connections. They are resistant to chemical wear, but not to mechanical wear. They also wear out over time due to temperature changes.

Teflon rings, like rubber ones, are only tougher due to their polymer composition – they provide not only tightness, but also resistance to high temperatures. Their Achilles' heel is mechanical wear.

Gaskets. They are used in rails and hydraulic booster reducers, in pumps, i.e., where working fluids and lubricants are present. Gaskets are responsible for the tightness of the entire assembly. They suffer from chemical and mechanical influences.

Spheres, also known as steel balls, are used in ball-type recirculation mechanisms. Although they are more durable and resistant to shock loads than toothed steering mechanisms, balls can still fail: they can start to crumble or flatten. The reasons for this are loads and impacts, misalignment in the gearbox, dirty or insufficient lubricant, corrosion, or exceeding the service life.

How to choose a repair kit for a steering rack

There are two ways to select a repair kit for a car:

- find and select it yourself by brand, model, and modification or by the car's VIN code, product number, or supplier number;

- seek help from professional consultants at companies that sell auto parts and repair kits.

The first option should only be used if the customer knows the exact information about the car modification, the product code of the repair kit, or the supplier code. The difficulty of searching on your own lies in the fact that most online stores do not have convenient search tools on their websites, which makes finding the right repair kit for a specific steering rack more time-consuming.

The best solution is to seek help from professionals, such as STS PARTS. Our experienced consultants will select the right repair kit for your car model and the nature of the repair, as well as answer any related questions, such as which lubricant or oil to choose for the rack. This will save you a lot of time and guarantee a correct and trouble-free repair, ensuring the reliability and long service life of the component in the future.

How to replace a repair kit

It should be noted right away: repairing such an important and responsible unit as a steering rack can only be done if you have mechanical skills and some experience in performing similar work. In addition, you need to have the necessary tools: not only general ones, but also special ones: so-called “crimpers,” mandrels, seal and bushing removers.

In the case of racks with power steering, repair is complicated by the need to intervene in the car's electronic systems. Therefore, we strongly recommend that all work on them be entrusted to professional workshops. However, units with power steering can be serviced in a garage if all the rules are followed. We will tell you how to do this correctly.

The first step is to remove the steering rack from the car, remove the dust covers, and disconnect the tie rods from it.

The next step is to disassemble the unit. We start with the distributor part:

- remove the distributor dust cover and retaining ring;

- remove the plug and nut from the bottom of the distributor;

- unscrew the adjusting nut, remove the rubber sealing ring, and then CAREFULLY knock out the side lock;

- carefully knock out the distributor, remove the oil seal and bearing, and check their condition.

Now move on to the rod part:

- Remove the support bushing.

- Pressing from the side of the distributor, squeeze the rod with the oil seal out of the housing.

- Remove the rod.

Before replacing the repair kit, check the condition of the rod and housing (including the distributor part) — there should be no wear or rust.

Now you can proceed to the replacement of the repair kit.

- Lubricate the inside of the rack housing, lubricate the seating surface for the new bushing and the new bushing itself.

- Replace the distributor repair kit: install new Teflon rings.

- It should be noted that Teflon seals stretch slightly when installed, so they will need to be compressed.

The work with the distributor is now complete, so we can move on to the rail.

- Press in the lower seal.

- Fit the new power seal into the rail housing.

- Put the rod into the housing, seat the second new seal on the rod, and put the bushing with new sealing rings in place.

- Put the distributor back in place. The rod should be turned with the teeth toward the worm gear. Lubricate the worm gear and carefully insert it into its seat.

- Put the bearing, upper seal, retaining ring, and dust cover in place—replace with new ones if necessary.

- Secure the rack rod and turn it over in a vise to install the side lock.

- Tighten the lower nut.

After completing the overhaul, be sure to adjust the rack.

Tips for mechanics installing the repair kit

When installing the seals, it is important to position them evenly and not damage their inner parts, otherwise they will not be able to function properly: for example, they will not be able to seal the power cylinder.

During the installation and removal of kit parts, it is important not to scratch or damage the surface of the rod or rail housing in any other way. This can lead to their failure and, as a result, additional repair procedures.

If, during the repair process, you realize that your qualifications are insufficient to perform the repair properly, do not hesitate to contact professionals immediately. Alternatively, you can contact us at STS PARTS. Our company has many years of experience in performing all possible work related to steering mechanisms and can fix any situation, no matter how complex.