Charging a Fiat 500 high-voltage battery that has discharged to a critical level

FIAT 500

Unlike many other electrical appliances, an electric vehicle does not like to see its battery discharged below a certain critical level - which is usually well above zero. This causes a whole range of problems, from accelerating the degradation of high-voltage batteries to problems with the electric vehicle's controllers and software. Let's talk about a typical case of an electric Fiat 500.

Returning a Fiat electric vehicle with a critically discharged high-voltage battery to life

We received an electric car with very low traction batteries. It was brought in by tow truck, as it had certainly lost its ability to move independently. The problem is typical for the Fiat 500 and many other EVs of this class: the car had been left in the car park for about two weeks with a partially charged battery. During the downtime, the batteries discharged below the permissible level, and the car's electric motor stopped starting.

Usually, in this case, there are still problems with the BMS (Battery Management System), it goes into protection. Even if the battery is fully charged, the car cannot be started in normal mode, you will have to go to the diagnostic menu, remove the lock by flashing the software.

Thus, the high-voltage battery was already so discharged that specific indicators could not be viewed through the diagnostic system. Notably, the indicator on the dashboard showed 37% charge. This is a typical undocumented error typical of Fiat - for some unknown reason, it cannot show values close to zero. Do not believe it, if the engine does not start, you should immediately seek help from qualified specialists.

In this situation, the only way out was to remove the battery and charge it with an external charger. To do this, we raised the car on a lift and removed the high-voltage battery pack using a hydraulic pole. It should be noted that this requires dismantling the rear beam of the Fiat 500 with the disconnection of the brake pipes.

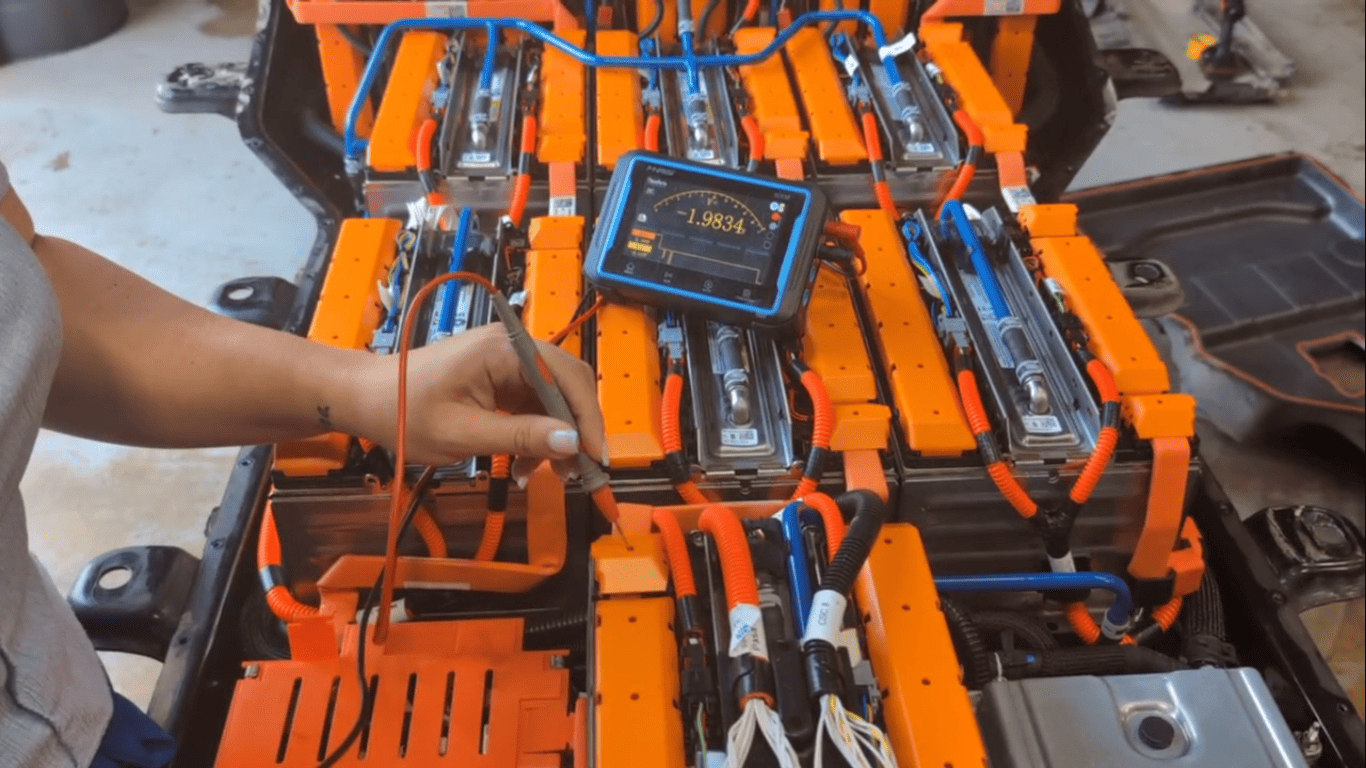

On the dismantled battery, each battery module was tested with a multimeter. The situation was disappointing: on average, the voltage at the contacts of each cell did not exceed 2V (despite the fact that this is less than the rated voltage of one battery). All the modules were approximately equal, except for one - it had even lower values. So, we need not only to charge but also to balance the high-voltage battery.

Since it is not possible to charge the car's batteries with a standard charger in such an emergency situation, as the BMS will not allow it, we used an external 400 V high-voltage power supply for charging. The charging current was low to minimise the risk of battery damage.

When the batteries were about 14% charged, the modules were measured again. The multimeter was already showing 22 volts, so we were on the right track. In total, the process of charging and restoring the high-voltage battery took about two days. After that, it was assembled and installed on the car.

After installing the rear beam and connecting its brake pipes, it was necessary to pump the brakes. It should be noted that this is not as easy as on cars with internal combustion engines. Like almost all other procedures, it also requires a connection to the car's diagnostic system.

And finally, how to avoid such a situation. Which does not have the best effect on the health of the high-voltage battery. In order to prevent the car's batteries from discharging below a critical level, if the electric car needs to be left for a long time, the gun must be left on in the charging port. In fact, this is written in the instructions for many cars, including the Fiat 500. And if trouble with the car does happen, feel free to contact us at STS.Electro. We will help in any, even the most difficult and non-standard situation.