High-voltage reed switch of an electric and hybrid car

In this article, we will discuss a compact yet impactful device responsible for the safety of the high-voltage circuit in cars. Understanding this component will help you make the most efficient use of your electric or hybrid vehicle while avoiding the risk of sudden stops and other critical malfunctions.

It's worth noting right away that the safety of high-voltage components in electric drive cars is ensured by numerous elements: high-voltage fuse, sealed housing, special protections, and the High-Voltage Interlock Loop (HVIL). But that's a topic for another time.

STS Electro is the specialized service center for electric cars and hybrids in Poland. We not only solve complex issues with high-voltage systems and software but also promote the culture of electromobility through educational publications like this.

Function of the High-Voltage Contactor

The high-voltage contactor is essentially a relay. It connects the 400-volt power line through an electromagnetic coil controlled by the 12-volt system from the 12V battery. In the high-voltage battery, there is a power contactor on each line (positive and negative). Both contactors engage when we turn on the ignition in the car, but not simultaneously – first positive, then negative.

The high-voltage contactor has two windings: pull-in and holding.

When the contactor is in a relaxed state, without power or open, no current flows through it. But as soon as 12V is applied to the contactor coil, it immediately closes. The metal core, under the influence of the electromagnetic field, presses the contact plate against the contact "fingers." And at the moment when the current starts to flow through the contactor, the pull-in winding is disconnected, leaving only the holding winding operational.

The pull-in winding has a much higher electromotive force (EMF) than the holding winding. Accordingly, if we constantly power the pull-in winding, the contactor will heat up significantly. As a result, it will fail.

The holding winding does not require a high EMF; it just needs to keep the metal core in the state in which it is, ensuring a reliable electrical connection between the contact plate and the contact fingers.

Types of Direct Current Contactors in Electric and Hybrid Cars

Power contactors come in two types:

- Sealed (Vacuum) Contactors: These are also called vacuum contactors because a vacuum environment (vacuum capsule) is created at the junction of the contact plate and the contact "fingers." The vacuum reduces the risk of a plasma arc occurring when the connection between the contactor plate and the power finger is broken. In other words, this is an additional safety guarantee.

- Non-Sealed Contactors: These contactors are designed for lower current. There is no vacuum environment inside. Such contactors are easier to manufacture and have a relatively low cost.

For example, hybrid cars with small high-voltage batteries typically use non-sealed high-voltage relays.

For reference, the Tesla Model S P100D is equipped with vacuum contactors that can briefly pass a current of 1500 Amperes. Hybrid cars have small high-voltage batteries and usually use non-sealed high-voltage relays.

Contactor Groups Based on the Mounting Method of the Plate on the Core Axis:

- Moveable Connection of the Contact Plate: This allows for some movement of the contact plate.

- Rigid Fixation between the Plate and the Core Axis: This provides a firm connection between the plate and the core axis.

Service Life of the High-Voltage Contactor

Every power contactor has its service life, measured in the number of switching cycles. On average, it is 25,000 times. To ensure that the contactor reaches its specified service life, the ignition should not be switched on and off under load.

For example, when the car is moving, and current is flowing from the battery to the inverter, if 12V power is not supplied to the high-voltage contactor at this moment, it breaks the connection. As a result, the power contactor's movable contact plate, under the action of the return spring, tries to detach from the contact point with the fingers – the contact point "burns," significantly reducing its service life.

What Can Happen If the Power Contactor in an Electric or Hybrid Car Is Faulty

There are several possible scenarios:

- The car signals an error in the high-voltage circuit with a warning on the dashboard: "Check Hybrid System," "Stop Safely Now," a yellow or red exclamation mark. After two or three messages, the car comes to a complete stop.

- The ignition does not turn off: The driver tries to turn off the ignition, but it does not work.

- Risk of electric shock: If the power contactor is faulty, and the contacts between the plate and the fingers are fused, the high-voltage circuit will be under constant voltage. An unqualified technician or the car owner might be at risk of electric shock if they attempt to deal with a battery problem on their own.

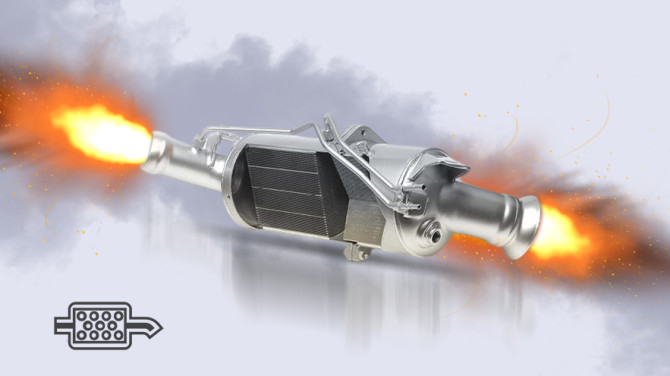

Power contactor of a Nissan Leaf in a disassembled state

Understanding the role of the high-voltage contactor in an electric or hybrid vehicle is crucial for both vehicle owners and technicians. Regular maintenance and timely replacement of faulty components contribute to the safe and efficient operation of the vehicle's high-voltage system.

Causes of High-Voltage Contactor Malfunction

Several key points can lead to the malfunction of the high-voltage contactor:

- Weak 12V Battery: A worn-out 12V battery may not provide sufficient voltage to the pull-in winding for the contactor to close without the occurrence of a plasma arc. Prolonged use of a weak battery can result in the burning of the power contactor.

- Driving Style of the Electric or Hybrid Vehicle: For instance, sudden acceleration from a standstill. This causes a brief but high electricity draw, potentially pushing the contactor's capacity to its limit.

Other Internal Failures: For example, if some cells in the electric or hybrid vehicle's battery are unbalanced (with low capacity), the Battery Management System (BMS) evaluates this situation and takes emergency action to remove the 12-volt power from the high-voltage relay. The contactor then forcefully breaks the battery connection to prevent damage to the entire power source.

Prevention of Contactor Malfunction

Monitor the Condition of the 12V Battery: Regularly check the state of the 12-volt battery. Scheduled replacement of the battery every three years, regardless of mileage, is recommended to avoid contactor issues.

Behavior During Short Stops of the Electric or Hybrid Vehicle: Leave the ignition on and shift the car into the parking mode during short stops. In this case, the DC/DC converter operates, supporting the 12-volt battery.

Replacement of the Power Contactor in an Electric or Hybrid Vehicle

How Many Contactors Need to Be Replaced

Typically, both contactors (on the positive and negative bus) in the battery need to be replaced simultaneously. While replacing one contactor may seem theoretically correct, in practice, it's a temporary solution. When one contactor burns, the quality of the connection of the second one deteriorates over time, eventually requiring its replacement. This leads to additional costs for removing, opening, and installing the battery.

Determining the Condition of the Contactor

Each contactor has its state, and it cannot be distinguished externally, whether it is a used component or a new one. The status of the device can be checked by measuring the resistance when applying 12 volts to it.

If the contactor is in good condition, the resistance will be the same in ten out of ten cases. However, if the resistance is lower or higher than the specified limits at least once in ten measurements, the unit is considered worn, and replacement is necessary.

Safety Measures

Replacing a fused (closed) contactor is a hazardous operation due to the high-voltage circuit. There is a high risk of electric shock. Therefore, servicing power contactors should be entrusted only to specialized service centers where technicians and electricians are certified to work with high voltage.

Never attempt to independently study the high-voltage battery's structure!

Technicians and engineers at STS have undergone special training for working with high-voltage equipment. The team is equipped with dielectric gear, specialized instruments, and other protective means.

There is a strict algorithm for dismantling power contactors:

- Use dielectric boots and gloves.

- Perform all manipulations with one hand.

- Avoid touching the battery casing.

- When dismantling the battery, disconnect the 12-volt battery.

- Disconnect the high-voltage fuse.

- Disconnect the high-voltage connector.

- Shield the battery casing from any external interference.

STS Electro Case Studies

Issue: The owner of a Nissan Leaf approached STS Electro with the problem that the ignition in his electric vehicle could not be turned off, and the current continuously flowed to the inverter, the electrical circuit did not break.

Solution: During computer diagnostics, a malfunction in the high-voltage contactor was identified. Both contactors were replaced, addressing the customer's request.

Toyota RAV4 EV

Issue: The car did not start. The owner brought it to STS on a tow truck.

Solution: During diagnostics, a malfunction in the power contactors was identified. The internal resistance of the contactors was checked, and three times out of ten, the values deviated from the specified parameters. Both contactors were replaced, and the car was back on the road.

Ford Focus Electric

Issue: The electric car did not start. Before this, the car's system had warned the owner several times about a high-voltage circuit problem, after which the car refused to drive.

Note: In this brand of electric cars, a power contactor malfunction is a common situation due to two factors. First: a weak 45-ampere-hour 12V battery. Second: two high-voltage batteries = four contactors. Initially, the low-power battery is subjected to overload.

Solution: The 12-volt battery and contactors were replaced, addressing the malfunction.

If you don't have time to figure it out, but want to check the status of high-voltage contactors, call STS, the first specialized service center for hybrids and electric vehicles.