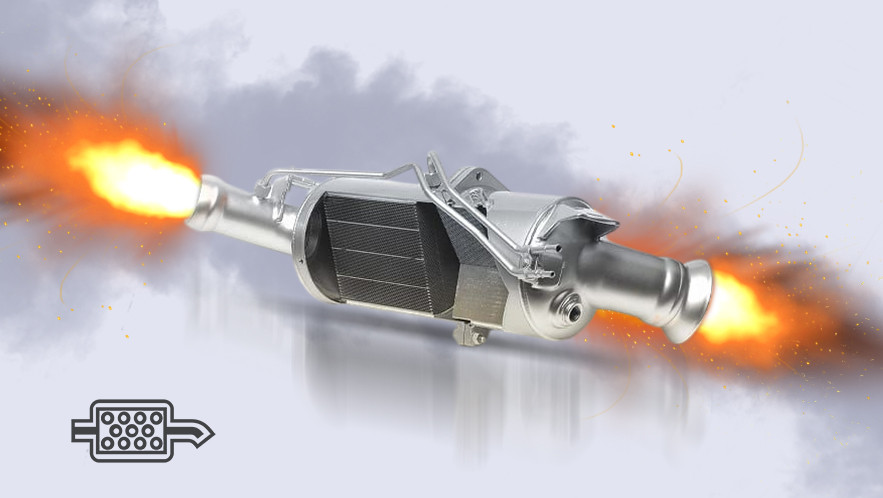

How to burn out a diesel particulate filter (DPF)

The diesel particulate filter (DPF) is an important part of the exhaust system of a modern diesel car. Its main task is to trap soot and solid particles formed during fuel combustion in a diesel engine. That is why timely DPF regeneration is critical to maintaining the effective operation of the cleaning system.

Many diesel car owners are interested in how to regenerate the DPF filter correctly and safely. This process involves heating the filter to a high temperature at which the soot is completely burned off and the filter regains its throughput capacity. DPF technology emerged in the early 2000s in response to strict environmental requirements for exhaust gases in order to reduce harmful emissions into the environment.

The purpose of regenerating a particulate filter

The main purpose of DPF regeneration is to restore its efficiency and reduce exhaust gas flow resistance. Without this procedure, the engine loses power and fuel consumption increases.

Regeneration is necessary to:

- maintain stable engine power;

- prevent excessive pressure in the exhaust system;

- avoid errors and the DPF indicator on the instrument panel;

- ensure regular soot burning;

- extend the service life of the filter.

When is DPF burning or regeneration necessary?

Below are the main situations when the particulate filter burning procedure is mandatory:

| Symptom | Possible cause | Required action |

| The DPF indicator (service message) has appeared on the dashboard | The soot filter is full | Perform DPF regeneration while stationary or driving |

| Reduced engine power | Excessive pressure in the exhaust system | Initiate regeneration or contact a service centre |

| Increased fuel consumption | Unsuccessful or incomplete regeneration | Have the filter cleaned at a workshop |

| Difficult engine start-up | DPF clogged with ash | Diagnostic inspection and filter flushing |

| Regeneration starts too often | Incorrect operation of the car or short trips | Drive on the motorway to complete the cycle or contact STS specialists |

How to force DPF regeneration

The cleaning process can be performed in three ways: automatically while driving, forcibly while parked, or at a service centre.

DPF regeneration while parked

If the DPF indicator is already lit, you can initiate forced regeneration in stationary mode. To do this, place the car on a level surface, warm up the engine, and then start the burning process using a diagnostic scanner. At this time, the computer supplies an additional dose of fuel to raise the temperature to 600–650 °C. The soot begins to burn, and the DPF burnout filter automatically completes after cleaning the cells.

DPF burnout while driving

The most common option is DPF burnout while driving, which occurs without driver intervention. For a successful cycle, the car must move at a constant engine speed (usually over 2000 rpm) for 15-30 minutes. The best option is to drive on a motorway, where the exhaust gas flow is stable and the required temperature for effective soot combustion is achieved.

Regeneration at a service centre

If the filter is too dirty or the DPF burning procedure does not help, professional cleaning is performed. In this case, specialists carry out DPF burning or washing on a special stand. This is safer than trying to burn the residues yourself, as excessive temperatures can damage the ceramic filter housing.

How long does the burning process take?

The duration of the procedure depends on the regeneration method, the level of clogging and the car model. Below are approximate figures:

| Regeneration method | Approximate duration | Note |

| DPF burning during driving | 15–30 minutes | Requires driving at a steady speed |

| DPF burning while stationary | 20–40 minutes | Depends on engine temperature and software mode |

| Cleaning at a service station | 1–2 hours | Complete flushing or regeneration under the supervision of specialists |

How often does DPF regeneration occur?

Under normal conditions, regular regeneration occurs automatically every 300–800 km. The frequency depends on the type of operation, fuel quality and engine condition. If the car is used mainly in urban conditions and does not accelerate to high temperatures, soot accumulates faster. Therefore, it is recommended to drive on the motorway from time to time to burn the DPF filter naturally.

Possible consequences of regeneration failure

If DPF burning is interrupted or does not start, the consequences can be serious:

- Decrease in engine power;

- Increased pressure in the exhaust system;

- Damage to the turbine or EGR valves;

- Active accumulation of ash;

- Increased fuel consumption and emissions;

- Failure of the filter itself.

What happens if the regeneration process is stopped

If the driver turns off the engine during an active cycle or reduces the revs, the DPF filter will not be fully cleaned. The system will attempt to resume the process later, but each interruption worsens the cleaning process, and eventually the filter will become completely clogged. In this case, only professional flushing will help.

Expert advice on avoiding problems

To ensure that the particulate filter burns without failure, STS experts recommend the following:

- Use high-quality diesel fuel;

- Do not interrupt the DPF burnout procedure after starting;

- Regularly drive on the motorway to complete the cycle;

- Monitor the DPF indicator and do not ignore warnings;

- Do not operate the car only for short distances;

- Perform diagnostic checks of the system during maintenance;

- Do not attempt to burn/clean the DPF yourself without experience or equipment.

How STS (Warsaw) solves the problem

At STS, DPF regeneration is carried out using high-tech bench equipment of our own production. This is a unique method that does not use aggressive reagents or acids.

Filter cleaning is carried out exclusively with water and compressed air pulses, which wash out soot and ash residues from the filter cells under high pressure. The method allows the filter's permeability to be fully restored without overheating and without the risk of damaging the ceramic.

During cleaning, the filter is constantly monitored on a special stand equipped with a flow rate sensor. The system tracks parameters before, during and after the procedure, recording changes in pressure and exhaust gas flow rate in real time. The entire process is controlled by an operator who can assess the effectiveness of cleaning at any time. If necessary, the test results can be printed or saved on a flash drive — this confirms the quality of the work performed and the complete restoration of the filter to working condition.

Why you should turn to professionals

Before attempting to burn out a particulate filter yourself, remember that such attempts often lead to overheating or destruction of ceramic elements. The professional DPF cleaning procedure at STS is a controlled and safe process that guarantees the complete restoration of the filter's service life.

The company has extensive experience working with diesel and petrol systems, its own technological base and certified specialists. STS uses diagnostic equipment that allows it to accurately determine the degree of contamination, initiate regeneration or perform cleaning with maximum effect.

Conclusion

Burning out the DPF filter is an integral part of maintaining the efficiency of a diesel car. And although the system is capable of self-recovery, sometimes you can't do without the help of specialists.

STS (Warsaw) is a workshop that not only performs DPF burning, but also deeply understands the nature of the process, offers safe hydrogen cleaning without chemicals, control of each stage and a professional approach. By turning to STS, the owner can be confident that their diesel engine will run cleanly, economically and at full power.