GPF filter - how it works, common problems, maintenance

Just a few years ago, few people thought about particulate filters in gasoline cars. Their use seemed logical only for diesel engines, where soot was noticeable and problematic. However, with the tightening of environmental requirements and the rapid spread of direct fuel injection technology, even gasoline engines began to produce solid particles in quantities that required filtration. This forced car designers to consider a gasoline particulate filter, or GPF (Gasoline Particulate Filter). Its purpose is to reduce the amount of exhaust emissions entering the atmosphere. Initially, it was installed on select premium brand models, but today it has become standard on most modern gasoline-powered cars in Europe. How does a particulate filter in gasoline engines differ from a DPF, how does it work, and what are its weaknesses? Let's take a look in this article.

Which cars are equipped with a GPF filter?

The GPF filter is mainly used in gasoline engines with direct injection (GDI), which is explained by the peculiarities of fuel combustion in them.

In classic gasoline engines, fuel is atomized in the intake manifold, where it has time to mix with air and partially evaporate before entering the combustion chamber. This ensures more complete combustion of the mixture and, consequently, less soot.

In contrast, in direct injection engines operating at pressures of up to 200–350 bar, fuel is injected directly into the combustion chamber. As a result:

- Some of the droplets do not have time to evaporate

- Local fuel oversaturation occurs

- Incomplete combustion occurs

- A significant amount of soot is produced, even more than in some diesel engines.

That is why European standards (Euro 6c, 6d-TEMP and beyond) require car manufacturers to install gasoline particulate filters on models with this type of injection.

Today, GPFs can be found in the following cars:

- Mercedes-Benz (M264, M260, and other turbocharged gasoline engines)

- Audi (TSI/TFSI, mainly from 2017)

- Volkswagen (TSI, including Golf, Passat, Tiguan)

- BMW (B48/B58 series — 2.0, 3.0 gasoline)

- Peugeot / Citroën (1.2 PureTech 110/130)

- Hyundai / Kia (1.0–1.6 T‑GDi)

- Toyota (2.0 Dynamic Force, 2.4T D‑4ST, etc.)

These cars are equipped with modern turbocharged gasoline engines with direct injection, which consume less fuel but operate according to a complex scheme: fuel is supplied under high pressure directly into the cylinders. This helps to reduce consumption, improve dynamics, and meet environmental requirements. However, this technology has a side effect — the formation of solid soot particles that need to be filtered out. This is exactly what a gasoline DPF filter is for.

The difference between DPF and GPF

Although both filters are very similar in design, a GPF filter is not a DPF in gasoline; it works according to different parameters:

| Parameter | DPF (diesel) | GPF (gasoline) |

| Regeneration temperature | ≈550–600°C | ≈650°C for soot burning, withstands up to 1100°C |

| Regeneration frequency | Active/passive | Mostly passive (exclusively active) |

| Fuel type | Diesel | Gasoline (GDI) |

| Regeneration target | High amount of soot | Lower, but significant portion of soot particles |

Does GPF cause problems for drivers?

Yes, despite the fact that the particulate filter in gasoline engines usually works “invisibly,” it has a number of features:

- Does not warm up during short city trips — the burning process does not start

- Often gives errors (P0420, P244A) — due to pressure drops and lack of air/gas pressure

- Sensitive to the condition of the pressure drop sensor

- Fuel consumption may increase due to incorrect regeneration

- Engine power drops when clogged

- Diagnostics with specialized equipment is required

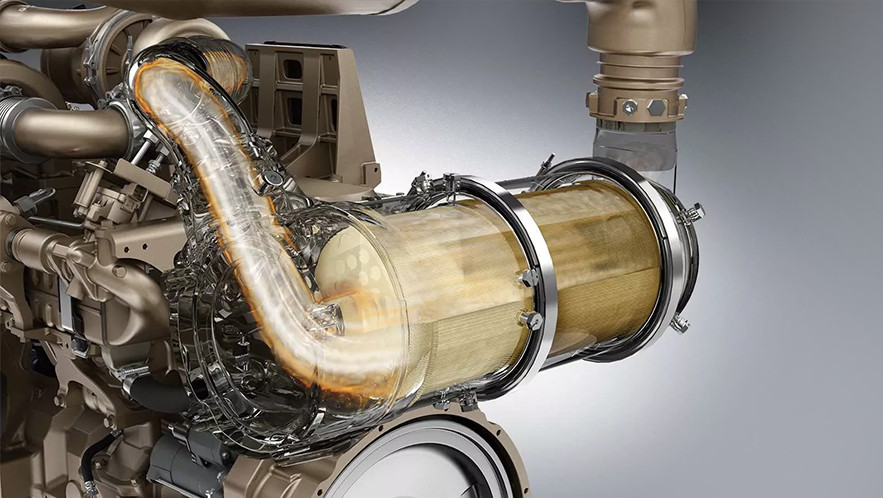

What is GPF regeneration?

GPF burning is the process of burning accumulated soot at high temperatures without driver intervention:

- Passive burning is activated at temperatures ≥600–650°C during acceleration or when driving without fuel injection into the exhaust (deceleration).

- Soot is converted into CO₂ and H₂O, cleaning the gasoline particulate filter channel

- Active regeneration (on gasoline) — rare due to the risk of increased NOₓ

- The system monitors the need for regeneration via a pressure drop sensor

GPF maintenance: tips

To take care of your GPF and prevent problems:

- Take regular highway trips (at least 20 minutes at speeds >3000 rpm)

- Refuel at high-quality gas stations

- Monitor the condition of the exhaust system and pressure drop sensor

- Identify the Check Engine error code as soon as possible

- Check the exhaust during diagnostics

- Use only manufacturer-recommended oils

- Use an OBD2 scanner to check the regeneration status and sensors

Common problems and solutions

| Problem | Cause | Solution |

| GPF clogging | Frequent short trips | Burn it out, drive on the highway for ≥20 minutes |

| Errors P0420/P244A | Poor performance of the pressure sensor | Diagnosis, replacement of the sensor |

| Increased fuel consumption | Incorrect combustion of soot | Check the injection and regeneration system |

| Loss of power | Increased pressure in the exhaust system | Clean or replace the filter |

| Constant CheckEngine | Regeneration or balancing error | Controller software check, reflashing, sensor repair |

When should you deactivate the GPF?

If the filter causes constant problems — errors pop up every time, the car shuts down, power loss occurs — you should consider deactivating the GPF.

Why is it not recommended to wash the GPF like the DPF?

In many cases, DPF or FAP can be effectively restored using hydropneumatic stands such as the MS 900, which combine water and compressed air to clean the filter channels. This approach works well with diesel particulate filters because they have stronger and thicker honeycomb structures made of cordierite or silicon carbide, designed for high loads and flows. In the case of a GPF filter, the situation is different:

- GPF has much thinner and more delicate channels than DPF – gasoline requires more thorough cleaning

- The honeycombs are made of materials adapted to higher combustion temperatures, but are not designed for contact with pressurized liquids

- Water and air delivered in powerful pulses can damage or destroy the ceramic structure.

- Even if visually intact after flushing, the filter may lose its flow capacity or develop microcracks, leading to invisible malfunctions.

Instead of flushing the GPF, in case of serious clogging, it is more advisable to:

- Burn off the soot, if the degree of accumulation allows it

- Or — remove the filter and reprogram it, provided that this is permissible in the region in terms of emission standards

Why choose STS?

STS specializes in the maintenance and repair of high-tech automotive systems, in particular the diagnosis and decontamination of modern exhaust gas cleaning systems. Our advantages:

- Use of certified software

- Our own electronic laboratory

- Warranty on work performed

- Service for both passenger cars and trucks

Service cost

Prices may vary depending on the car model and complexity, but are currently approximately as follows:

| Service | Approximate cost |

| GPF filter diagnostics | from 100 zł |

| Burning or regeneration | from 250 zł |

| Physical removal of the GPF filter | 600–800 zł |

| Control unit reflashing after removal | 500–700 zł |

| Complete deactivation of the GPF control system | 1000–1300 zł |

The GPF filter effectively reduces soot emissions, but requires active maintenance: regeneration, diagnostics, and is sensitive to the condition of pressure sensors. Its temperature can actually reach over 1100°C at peak loads. If the system fails, professional decontamination from STS in Warsaw comes to the rescue.