Electric car battery: how to choose

The heart of any electric car is its battery. It determines the range, operating costs and even the safety of the vehicle. When considering which battery to choose for an electric car, many drivers are faced with a huge amount of information, which sometimes only complicates the process. In this article, we will take a detailed look at which electric car battery is best suited for different situations, what types of batteries are available, what parameters should be taken into account, and we will also provide practical advice for drivers in Poland.

Types of batteries for electric cars

Several basic high-voltage battery technologies are used in modern electric transport. Each has its own advantages, disadvantages and areas of application. Let's look at them in order of appearance, development and popularity.

Nickel-metal hydride batteries (NiMH)

One of the oldest technologies, used since the 1990s. NiMH batteries are known for their stability, relatively low cost and fairly long service life.

- Advantages: cheaper to manufacture, resistant to numerous charge/discharge cycles, safer than lithium-ion batteries.

- Disadvantages: low energy density, heavy weight, poor efficiency under high loads.

- Where they are used: mainly in first-generation hybrids (Toyota Prius, Honda Insight). Today, new hybrid models are gradually switching to lithium-ion solutions.

Lithium-ion batteries (Li-ion)

The most common type in modern electric vehicles. The principle of operation is based on the movement of lithium ions between the cathode and anode. There are several key subtypes:

NMC (nickel-cobalt-manganese)

- Advantages: high energy density, providing a long range; good performance in different modes; proven technology.

- Disadvantages: high cost; fire hazard; dependence on scarce metals (cobalt, nickel).

- Where it is used: widely used in most modern mid-range and premium electric vehicles (BMW, Volkswagen, Hyundai).

NCA (nickel-cobalt-aluminium)

- Advantages: even higher energy density compared to NMC, longer range, reduced cobalt content.

- Disadvantages: complexity of production; high fire hazard; limited number of manufacturers.

- Where it is used: in models where maximum range and power are key. The most famous example is Tesla (Model S, Model 3 in Long Range versions).

LFP (lithium iron phosphate)

- Advantages: high safety, thermal stability, long service life (up to 3,000–4,000 cycles), lower price.

- Disadvantages: lower energy density; slightly lower range.

- Where used: budget and mid-range electric vehicles, especially those manufactured in China (BYD, some versions of Tesla Model 3 and Model Y, MG).

LiPo (lithium polymer)

- Advantages: high energy density, ease of forming any form factors, flexibility of integration into the car design.

- Disadvantages: higher cost, fire hazard, complexity of production.

- Where it is used: mainly in specialised or sports electric vehicles, where compactness and lightness of the battery are critical.

Common problems with lithium-ion batteries:

- Fire hazard. In case of mechanical damage, overcharging or overheating, ‘thermal runaway’ and ignition are possible.

- Ethical issues. Cobalt mining is often associated with child labour and unsafe conditions in African countries (DR Congo). Lithium mining in South America requires huge amounts of water, which harms local communities and the environment. Another problem is the disposal of used batteries, as the toxic elements they contain can leach into the soil and water and contaminate them.

Promising technologies

Solid-state batteries

- Advantages: the use of a solid electrolyte allows for ultra-high energy density, increased safety and durability.

- Disadvantages: currently, high production costs and lack of a mass market.

- Where they are used: so far, only in research samples and premium developments (Toyota, BMW, QuantumScape).

Sodium-ion batteries

- Advantages: cheaper to produce, less dependent on scarce metals, more environmentally friendly.

- Disadvantages: lower energy density compared to lithium-ion batteries.

- Where they are used: considered as an option for budget electric vehicles and urban transport. The first serial models have already been presented by CATL.

Comparative table of battery types

| Battery type | Advantages | Disadvantages | Where they are used |

| NiMH | Cheaper, stable, durable, safe | Low energy density, heavy weight, low efficiency | Hybrids of the 1990s – 2000s (Toyota Prius, Honda Insight) |

| NMC | High energy density, long range, reliable technology | High cost, cobalt dependency, fire hazard | BMW, VW, Hyundai, etc. |

| NCA | Maximum energy density, long range, less cobalt | More expensive, fire hazard, few manufacturers | Tesla (Model S, Model 3 LR) |

| LFP | Safe, thermally stable, cheaper, durable | Lower energy density, shorter range | BYD, Tesla Model 3/Y (partially), MG |

| LiPo | Compact, lightweight, high density, flexible form factor | Expensive, fire hazard, difficult to manufacture | Sports and specialised electric cars |

| Solid-state | Ultra-high energy density, safety, durability | Very expensive, still experimental | Toyota, BMW (R&D), QuantumScape |

| Sodium-ion | Cheaper, environmentally friendly, do not require scarce metals | Lower energy density, new technology | CATL, budget electric cars (in the future) |

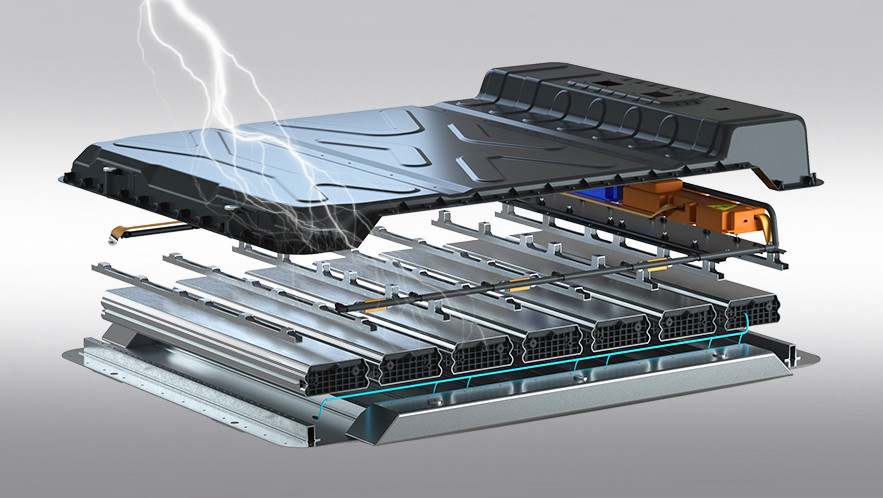

Key parameters and properties of batteries

| Parameter | Description | Value for the user |

| Battery capacity (kWh) | Amount of energy that the battery can store | Determines the range |

| Voltage and number of cells | Affects operating power and performance | Responsible for the car's dynamics |

| Service life | Number of charge/discharge cycles before significant degradation | Affects long-term costs |

| Charging time | Depends on the charger and technology | Important for ease of use |

| Cooling system | Protects the battery from overheating | Affects safety and durability |

| Modular design | Division into separate blocks (modules) | Facilitates repair and replacement of parts |

Are electric car batteries really environmentally friendly?

Although electric car batteries do not emit harmful gases during operation, their production and disposal remain challenging. The use of materials such as lithium, cobalt and nickel raises environmental and ethical concerns. At the same time, recycling technologies are developing rapidly, and battery reuse programmes are already being implemented in the EU.

The cost of replacing a battery in an electric car

The price of a new battery for an electric vehicle can vary from €5,000 to €20,000 depending on the brand and capacity. The cost is also determined by whether it is possible to replace individual modules or only the entire battery. In the future, prices are expected to gradually decrease due to mass production.

Leading brands of battery systems

- Panasonic

- CATL

- LG Energy Solution

- Samsung SDI

- BYD

- SK Innovation

- Northvolt

Criteria for choosing a car battery

To choose the right high-voltage battery for an electric or hybrid vehicle, there are several key factors to consider. Here are the main criteria to pay attention to:

- Battery capacity (kWh) and expected range.

- Chemistry type (NMC, LFP, LiPo).

- Compatibility with the vehicle in which it will be installed.

- Compatibility with existing charging stations.

- Manufacturer's warranty and service life.

- Availability of cooling and protection systems.

- Possibility of replacing individual modules.

Battery maintenance: facts and myths

The relative novelty of the technology and the large number of false or unqualified publications about electric vehicles have led to the emergence of stereotypes in society that often have no basis in reality. Let's look at some of the most popular myths about electric car batteries.

| Statement | Fact or myth | Comment |

| Batteries should always be charged to 100% | Myth | Frequent charging to 100% damages most Li-ion batteries, with the exception of LFP batteries. |

| Batteries quickly lose capacity in winter. | Fact | Low temperatures reduce performance. |

| You cannot leave a car with a low charge for a long time. | True. | This accelerates degradation. |

| Regular software updates affect the battery. | True | Correcting charging algorithms increases efficiency |

| The battery does not require any maintenance at all | Myth | Condition and temperature monitoring is required |

Useful recommendations for Polish drivers

- Plan your charging, taking into account the development of the network of stations in Poland.

- In winter, try to charge your car in a warm room or use pre-heating.

- Only use certified chargers.

- Keep an eye on your car's software updates.

- Avoid frequent trips with a charge below 10%.

Conclusion

High-voltage batteries are the heart of modern electric and hybrid vehicles. The type of chemistry, technology and build quality determine the range, durability, safety and price of the car. Despite the development of new promising areas, lithium-ion batteries of various configurations remain the most common, providing a balance between energy capacity and resource.

At STS (Warsaw), you can always get professional service for high-voltage batteries: repair, balance restoration, replacement of individual cells. It is also possible to purchase new batteries or modules with a warranty and turnkey installation. This ensures the reliability, safety and long service life of your electric or hybrid vehicle.