How the steering rack works in a car

To understand how a steering rack works, you need to remember its main purpose. This unit is a key element of the steering system, transmitting force from the steering wheel to the wheels of the car. This allows the driver to control the direction of travel and ensure safety while driving. The mechanism plays a decisive role in the comfort and precision of vehicle control, and also directly affects its performance and durability.

Functions of the steering rack in a car

The questions “what is the steering rack for” and “what is the steering rack in a car” have a simple answer: it is a mechanism that connects the steering wheel to the wheels, ensuring their synchronous movement. Thanks to it, even the slightest turn of the steering wheel is instantly transmitted to the wheels, allowing you to maneuver the car accurately in all conditions.

The main functions of the steering rack:

- Provides a direct connection between the steering wheel and the wheels for effective turning.

- Dampens vibrations from the road, increasing driving comfort.

- Amplifies movement from the steering wheel to the wheels (in cases where a power steering system is installed).

- Promotes stability and precision of control, especially at high speeds.

Thanks to these functions, the steering rack is an element without which it is impossible to imagine a modern car. Its proper operation ensures safe and predictable maneuvers on the road.

Design of a car steering rack

To understand what a steering rack is and how it works, you need to examine it in detail. The modern design of a steering rack includes many components that work together to transfer movement from the steering wheel to the wheels with minimal loss.

The steering gear usually consists of:

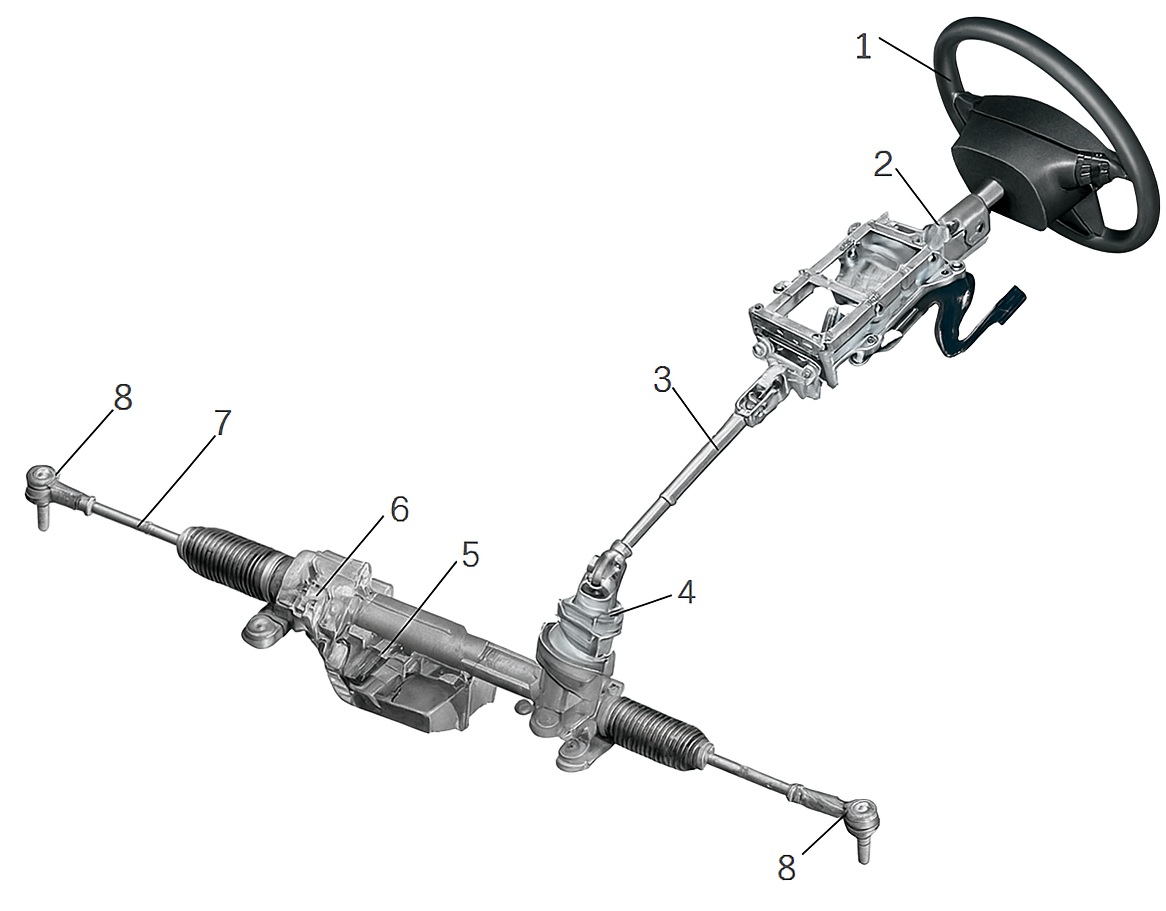

The photo below shows the most common mechanism in modern passenger cars — a steering rack with electric power steering (EPS):

- Steering wheel

- Steering column

- Cardan shaft

- Torque sensor on the steering wheel

- Electric power steering

- Steering mechanism

- Steering linkage

- Steering linkage end

Regardless of whether it is a hydraulic or electric steering rack, the principle remains the same — transferring and amplifying the force from the steering wheel to turn the wheels.

Types of steering racks

Depending on the design and method of amplification, there are several main types of steering racks. They differ in complexity, cost, and maintenance requirements.

The main types of steering racks are:

Each type has its own characteristics and maintenance requirements, but the main task for all of them is the precise and safe transmission of force from the steering wheel to the wheels.

The most common malfunctions and damage to the steering mechanism

Constant loads, road shocks, and natural aging of materials can cause the steering rack to fail over time. Such steering rack failures affect handling and overall safety.

| Symptom | Possible malfunction | Remedy |

| Knocking in the steering wheel | Wear on teeth or bushings | Repair or replacement |

| Heavy steering | Low fluid level, damage to the power steering pump or EPS motor | Add fluid, eliminate errors, regenerate the steering rack |

| Fluid leak | Damaged seals, gaskets | Replace seals or regenerate unit |

| Car pulls to one side | Worn inner tie rods or rack teeth | Repair or replacement |

| Steering wheel play | Worn steering system components | Rack repair or replacement |

Upon noticing the first symptoms of steering problems, the driver should contact a repair shop for diagnosis as soon as possible. This will prevent more serious damage and expensive repairs in the future.

Cost of purchasing a car steering rack

The price of a steering rack depends on the type of system, the model of the car, and whether it is a new part or a refurbished one. Refurbishment often allows for significant savings while maintaining full performance of the unit.

| Steering rack type | New price | Price after regeneration |

| Mechanical | from 750 PLN | from 400 PLN |

| Racks with hydraulic booster | from 800 PLN | from 500 PLN |

| Rails with electric booster | from PLN 1000 | from PLN 600 |

When choosing between regeneration and replacement with a new or refurbished unit, it is worth consulting with specialists who will advise you on the best option for your particular case, taking into account the degree of wear and specific malfunctions of the steering rack.

Important: STS.Parts always has steering racks in stock that have been professionally refurbished using high-quality original spare parts, which are almost as good as new but cost much less. This is a great opportunity not only to save on repairs but also to speed them up by handing over your faulty unit for credit.

Ways to extend the service life of the steering rack

To ensure that your steering rack meets all reliability requirements, follow these simple operating rules.

- Regularly check the level and condition of the fluid in the power steering system.

- Keep an eye on the condition of the dust covers and seals to avoid contamination of the unit.

- Have periodic preventive inspections carried out at specialized workshops.

- Carefully navigate potholes and obstacles to minimize the risk of suspension impact.

- Do not ignore unusual noises or rattling — they often signal a malfunction.

- Contact a specialist to repair or replace the steering rack at the first signs of wear.

Careful handling of the steering system, timely preventive maintenance, and visits to a professional workshop — such as STS — will help you avoid costly breakdowns and maintain maximum control and safety of your car.