What "diseases" steering columns?

Every automotive component has its challenges and issues. We previously discussed faults in steering gears and power steering pumps, and now we will delve into steering columns with and without power assistance.

What should you know about steering columns?

The steering column of a passenger car is a mechanical or electromechanical unit that connects the steering wheel to the steering rack. Its main function is to transfer the steering force to the steering rack. Additionally, some columns provide protection to the driver in case of accidents. The column connections are at an angle of up to 15°, allowing the device to collapse and avoid hitting the driver's chest during a collision.

Generally, the unit consists of the following elements:

- Upper steering shaft: One end of this part has threads to which the steering wheel and supporting nut are attached. The other end is connected by a crosspiece to the universal joint of the steering shaft (resistant to damage). In columns with electric power assistance, a worm gear is located on the upper shaft, transferring force from the electric drive worm to the shaft.

- Crosspieces: Typically, there are two crosspieces in the columns.

- Column housing: Controls the position and protects the upper shaft, as well as the built-in unit and the assistance module (if the unit has assistance). It is attached to the body on brackets.

- Damage-resistant shaft: Connects the upper shaft to the steering rack distributor through universal joints, and in the event of impacts or accidents, it collapses like a telescope, dampening the impact to prevent the steering column from hitting the driver's chest.

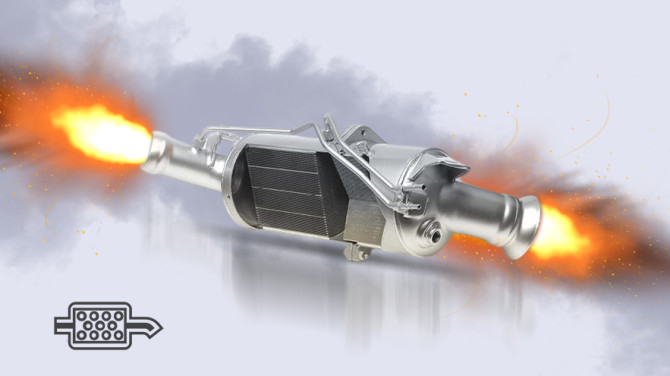

- Assistance module: In the case of electric power assistance, the electric assistance module contains a control board, a steering angle sensor, a copper-wound electric motor, a brush assembly with copper brushes, and a connector group with cables. The steering angle sensor detects the angle, direction, and angular speed of the steering wheel turn and transmits the obtained data to the board, which accelerates the electric motor to the desired speed and in the correct direction. The worm gear is attached to the rotor of the electric motor, which transfers force from the electric drive to the worm gear of the upper steering shaft. All assistance components are housed in a casing that protects them from moisture and dirt.

- Upper and lower protective covers: These elements are located below and above the steering wheel, protecting the steering column along with the built-in components.

- Turn signal and wiper switches, ignition and steering lock system, steering lock system, etc.

Construction of Electric Power Steering Column

The operation of a mechanical steering column is not overly complicated. The driver turns the steering wheel, which is connected to the upper shaft. The force from the part, through the crosspiece, is transferred to the damage-resistant shaft, which, in turn, rotates the second crosspiece and transfers force to the steering rack distributor. The subsequent actions are the same as in a mechanical column—the upper shaft moves the "screw," which shifts the pin connected through steering links and tie rods, and the car turns in the correct direction.

Operating Principles of Electric Power Steering Column

The operation of a device with electric power assistance is slightly more complex. When the driver turns the steering wheel, the steering angle sensor measures the angle, direction, and angular speed of the upper shaft's rotation. The sensor transmits this data to the electronic control board, which activates the electric motor. The "worm" winds the worm gear of the steering shaft, increasing the force.

The subsequent actions are the same as in a mechanical column—the upper shaft turns the "safety shaft," which rotates the distributor, and so on. When the driver releases the steering wheel, the electric motor returns the steering wheel to the neutral position.

Steering columns without assistance can be damaged due to mechanical faults, such as part wear, rust, or strong impacts. If a vehicle has a unit with electric assistance, the described problems are compounded by failures in the electric drive and electronic errors.

First, let's consider mechanical faults and then move on to possible electric power assistance issues.

Mechanical Faults in Steering Columns

Mechanical damage to steering columns includes:

- Thread wear on the upper shaft to which the steering wheel is attached, leading to axial play and knocking in the steering wheel.

- Rust on the spline connections of the "safety shaft," causing axial play and knocking in the steering wheel. Worn spline connections will also creak and grind when turning the steering wheel and driving on bumpy roads.

- Wear of the bearing bushing of the upper shaft, causing radial play and knocking in the steering wheel.

- Worn bearing support of the upper shaft, rust, or sagging, resulting in radial play, knocking, creaking, and grinding when turning the steering wheel and driving on bumpy roads.

- Worn mounting brackets of the housing unit, causing knocking and knocking of the unit along with the shaft.

- Rusty crosses between the shafts. In the event of such a failure, the driver will hear unpleasant creaking and grinding when turning the steering wheel, and the steering wheel may move sporadically or completely jam in one position.

- Loose covers on the column, and during movement, the elements fly and squeak.

Let's take a closer look at each of the faults.

Worn Thread on the Upper Shaft, Axial Play, and Knocking in the Steering Wheel

This issue arises from natural mechanical wear if the steering wheel is incorrectly installed on the shaft or if rust appears. If the thread is damaged, the driver may feel the steering wheel moving forward and backward, causing knocking. To resolve the problem, the worn part needs to be replaced. Careful driving and professional maintenance can help extend the life of the shaft thread.

Rusting of the splined connection of the safety shaft

Mounting of the unit rarely fails due to ordinary mechanical wear. More often, the cause of damage is rust on the spline connection, gradually destroying the teeth of the connectors.

Where does rust come from? Often, drivers are to blame, especially in winter when they don't shake off snow from their shoes. Snow in the cabin melts, and moisture gets under the pedals, where the steering column drive shaft is located. It's simple—under the influence of moisture, the part gradually rusts, corrosion enters the spline connection, and over time, it destroys it.

How to understand that the spline connection of the steering column drive shaft is rusty:

- When turning the steering wheel, the driver hears crunching, knocking, and grinding in the pedal area.

- The steering wheel sticks or sometimes locks.

If there is rust on the spline connection.

- The steering wheel locks, the car becomes uncontrollable and unpredictable.

- Other elements of the steering system rust.

- Power assistance resets or disappears entirely (if available).

- In the case of deep corrosion and if the driver does not fix the fault for a long time, the assembly parts do not make contact, and the car completely loses control. In this case, there will be axial play on the steering wheel.

In the case of deep corrosion during an accident, the cross may not be fully assembled, leading to serious column damage and potential harm to the driver.

Found one of these signs? Sign up for a diagnosis at a car service specializing in steering system repairs. The assembly with mild corrosion can be repaired, while a severely damaged assembly needs replacement.

To prevent such problems, make sure moisture does not accumulate under the mat near the pedals and do not forget about routine and seasonal maintenance. And, of course, you can check the condition of the steering column components yourself.

Worn Bushing of the Upper Shaft

The upper shaft is located in the housing tube, which controls the position of the part. To prevent the shaft from flying, there is a supporting bushing in the tube. The wear of this bushing results from mechanical friction and rust on the shaft—it is a common problem for many steering columns.

A shaft with a worn bushing will knock and fly radially, making the fault quickly noticeable. The only way to solve the problem is to replace the bushing with a new one.

Worn Bearing Support of the Upper Shaft, Damage, or Rust

The bearing supports the position of the upper shaft and provides its axial movement. The fault arises due to rust on the part, strong impacts, or collisions with obstacles, as well as natural mechanical wear.

Signs of a fault include radial play, crunching, knocking, and grinding when turning the steering wheel and driving on bumpy roads. Damage can only be fixed by replacing the bearing with a new one.

Worn Mounts of the Housing, Play, and Knocking of the Housing with the Upper Shaft

The column housing is securely attached to the car body. If the mounts of the housing wear out or loosen, the housing with the shaft becomes loose and knocks. If you often drive on rough roads and like aggressive driving, don't be surprised if a few months after purchasing the car, the steering wheel starts to loosen and knock on every turn.

To solve the problem, tighten the loose mounting screws. If the screws are rusty or the thread is torn, seek help from a workshop. To prevent mounting problems, be cautious and attentive on the road, and also perform inspections on time.

Rusty and Oxidized Crosspieces Between the Shafts

Crosspieces transfer force between the shafts of the column and further to the steering gear. Crosspieces also provide the necessary angle between the shafts, increasing the safety of the column and reducing the risk of serious driver injury during a collision.

Crosspieces rust for the same reasons as the spline connection of the steering column drive shaft. Most often, the lower crosspiece rusts, which connects the column to the steering rack and is located in the lower part of the car close to the road surface. This means that moisture and dirt first reach the lower crosspiece, and the upper part is relatively safe.

Rusty crosspieces creak and rattle when turning the steering wheel and driving on bumpy roads; the steering wheel may lock in one position, and the car may become uncontrollable at any time. If rust appears on the crosspieces, the elements must be replaced because they cannot be repaired. To get such a service, contact a workshop, as you probably won't be able to replace the crosspieces in garage conditions.

How to protect steering column parts from rust? It's simple—regularly visit a workshop for routine and seasonal maintenance, and don't forget to regularly check the condition of the steering gear. Found signs of a fault? Immediately contact a specialized car service for steering system repair. This will help prevent serious faults and eliminate defects and rust in a timely manner.

Flying and Knocking Covers

On the one hand, it's challenging to call it a fault; it's more of an annoying problem that is irritating and interferes with concentration. On the other hand, covers protect electronics and wires under the steering wheel, and sometimes the entire loose filling of the device can simply fall into the driver's lap.

If the cover fastenings are intact, simply put the elements back in place. But if the fastenings break or are seriously damaged, you need to buy new ones.

Faults and Errors in Electric Power Assistance

Electric power assistance steering columns may differ in construction, but the operating principle and characteristic faults are the same.

A yellow icon indicates a power assistance failure, while red indicates that the assistance is completely disabled.

- What problems can occur with electric power assistance:

- Drive or worm gear mechanism components are rusty, clogged, or worn out.

- Worn bearing support of the electric drive worm shaft.

- Moisture and/or dirt have entered the unit, causing the electronics to hang and short circuit.

- Soot or scale has appeared on the copper elements of the drive, disrupting the amplifier's operation.

- The steering angle sensor is worn, causing assistance failure.

- Malfunctions in the Control Unit, leading to errors in the operation of the assistance.

Signs of a fault: Heavy steering; intermittent steering wheel turns; knocking that occurs only when the engine is running; warning signals on the dashboard indicating assistance malfunctions.

The most important thing to remember is not to try to repair the electric power assistance steering column yourself, even if you've watched a hundred instructional videos on the subject. Also, don't trust the repair of assistance to non-specialized workshops and garage-type car workshops—employees of such services likely lack the experience and equipment to repair electric columns.

If you notice signs of a fault in the power assistance steering column, contact a specialized steering system repair station that has an electrical department. To check and repair steering columns, you need experienced and qualified specialists, as well as specialized and modern equipment and tools.

As for preventing faults in steering columns, it's simple—conduct inspections and service on time, be careful and attentive on the road, and use the services of only trusted and specialized workshops. This will significantly increase the lifespan not only of the column and assistance but also of other control units.