Repair of PSA EB2 (1.2 PureTech) engine: a case study from STS Warsaw

PEUGEOT 308

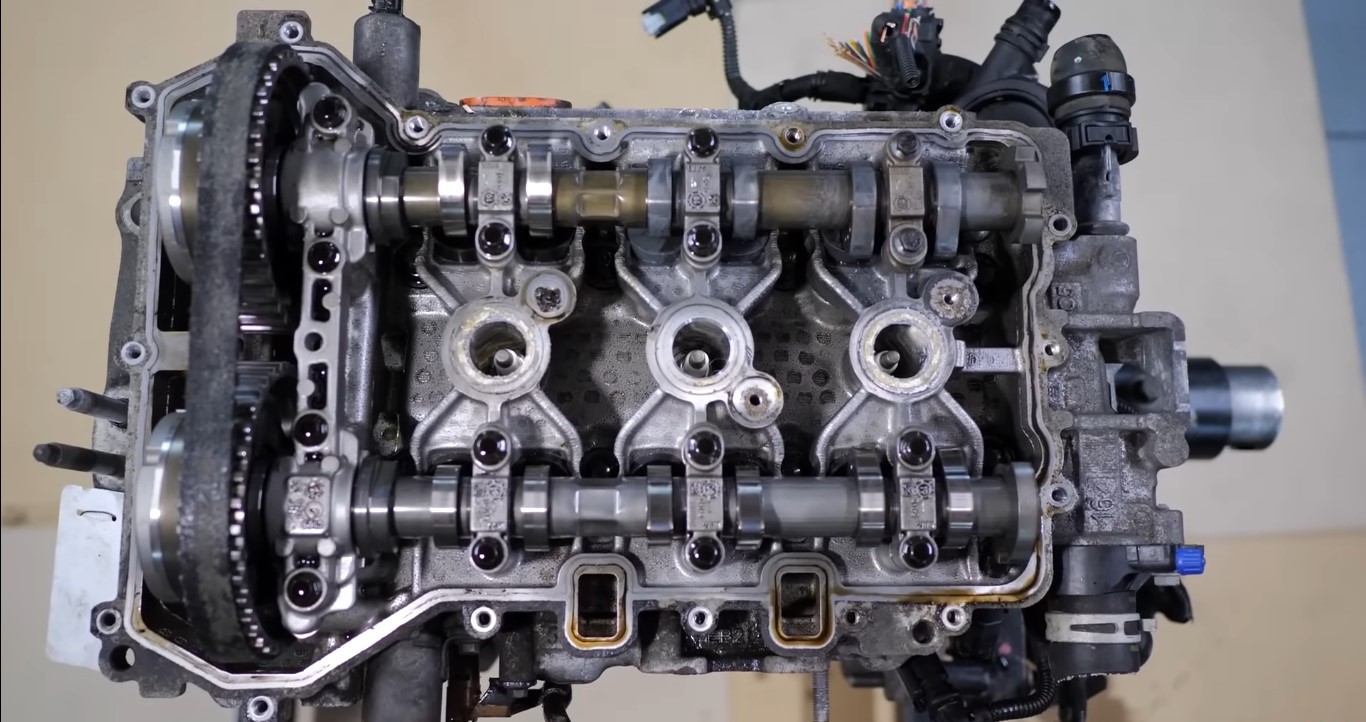

The EB2 series engines (1.2 PureTech) from PSA Group were introduced in 2012 as a modern alternative to the older TU series. On paper, it looked perfect: a compact 3-cylinder unit with low fuel consumption, turbo versions with up to 155 hp, and environmental friendliness. But in practice, PureTech engines quickly gained a reputation as the ‘weak link’ due to a number of design flaws. Most often, problems appear after 60-80 thousand kilometres of mileage, but there have been cases much earlier.

Main problems with PureTech

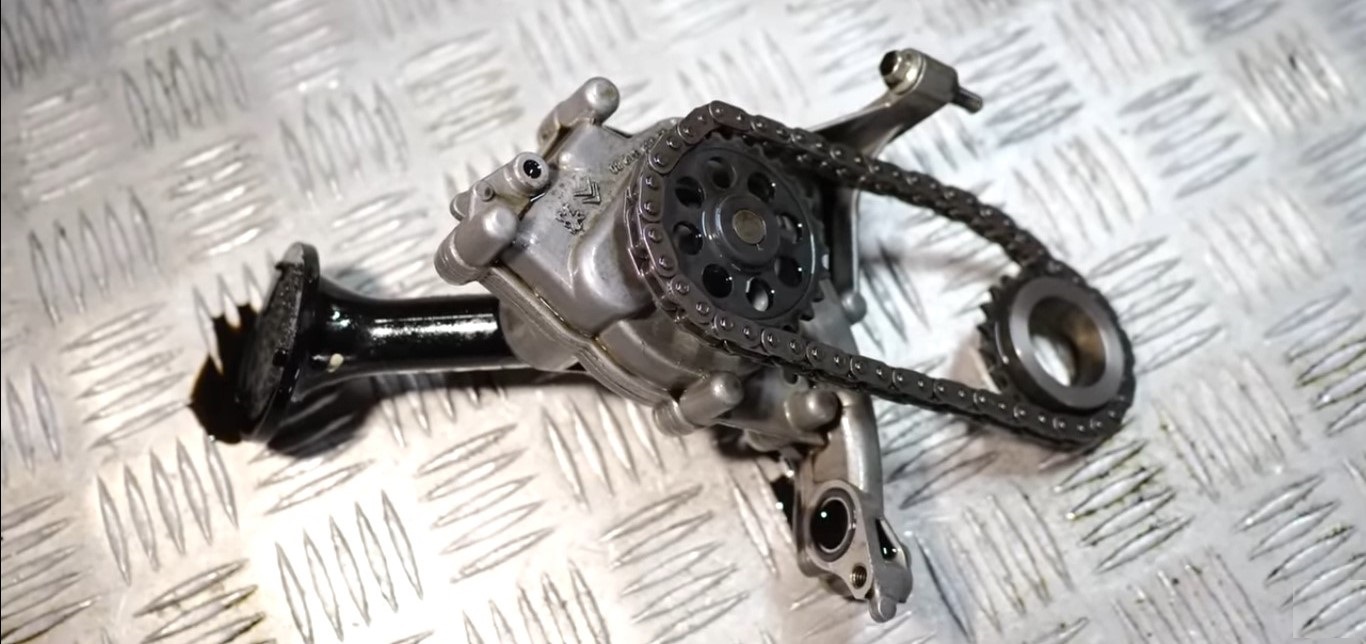

- Timing belt in an oil bath. Unlike the classic dry design, here the belt is in constant contact with engine oil. The manufacturer explained this by reduced friction and better fuel economy. In addition, the condition of the belt can be monitored through the oil filler neck.

However, in practice, the belt begins to delaminate, crumble and produce dust that clogs the oil channels. As a result, the oil and vacuum pumps operate in critical mode. This can lead to a drop in oil pressure, brake system failure and major breakdowns.

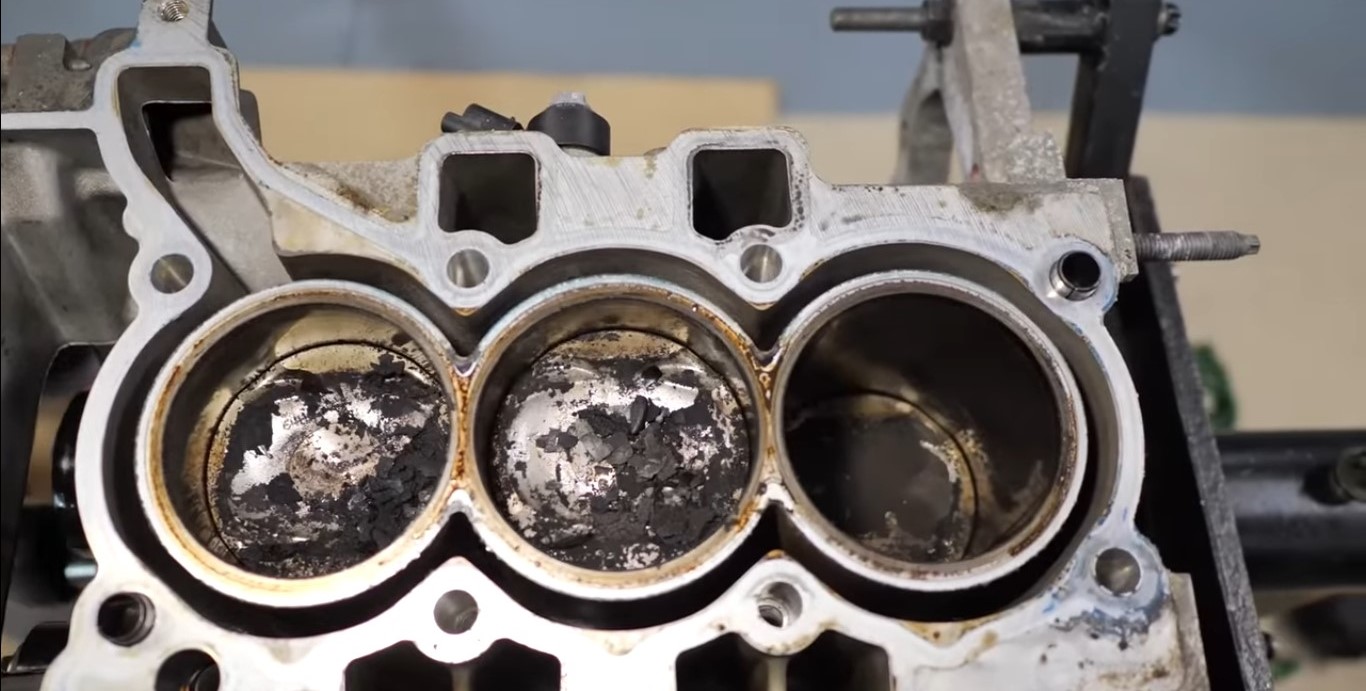

- Oil consumption. Consumption can reach 1 litre per 1000 km — a critical indicator for a modern engine. The main reason is piston ring sticking due to oil degradation and high operating temperatures. Drivers are forced to constantly monitor the level and top up the oil, otherwise they risk ‘seizing’ the engine after a few thousand kilometres. Weak crankshaft half-rings. They cannot withstand the loads and cause axial play. If it exceeds 0.5 mm, the engine is no longer safe to operate. The belt may slip off the gears, the valves will collide with the pistons, resulting in complete destruction of the cylinder head. The worst thing is that the half-rings are not sold separately: you have to replace the block or the entire engine.

- Absence of hydraulic compensators. The valves are adjusted using ‘cups’ (calibrated tappets). With wear, they lose their accuracy, and the adjustment has to be done manually. For owners, this means additional costs and complicated maintenance. If the car is equipped with LPG, the thermal load on the valves is higher, so adjustment may be necessary after 30-40 thousand kilometres.

- Thin sleeves in the aluminium block. PSA made thin-walled cast iron sleeves for lightness and compactness. They wear out much faster, and repair sizes are not provided. In essence, the engine is ‘disposable’: in case of critical wear, the only option is replacement.

- Integrated exhaust manifold in the cylinder head. This solution speeds up engine warm-up for the sake of the environment, but makes repairs much more difficult. If damaged, the entire cylinder head has to be replaced, which is very expensive for the owner.

Engine repair case from STS Warsaw

Our STS workshop in Warsaw received a 2018 Peugeot 308 with a 1.2 PureTech (EB2) engine. Symptom: the oil pressure warning light was constantly on.

- First, the pressure sensor was replaced, but the problem remained.

- We connected a pressure gauge and confirmed that the oil pressure was significantly lower than normal.

- It was decided to disassemble the engine.

The cause of the problem: clogging of the oil pump intake screen with debris from the timing belt. Rubber crumbs almost completely blocked the oil supply.

The owner was lucky — he contacted our service in time. In such cases, the following often happens:

- Wear of camshafts and their necks. Oil starvation quickly ‘kills’ the upper part of the engine.

- Wear of main bearings and crankshaft. Even a few hundred kilometres without pressure can result in serious repairs.

- Carbon deposits on pistons and destruction of the factory cylinder honing. This worsens sealing and further increases oil consumption.

- Clogging of the vacuum pump. This directly affects the braking system, lengthening the braking distance and creating a risk of an accident.

Work performed

- Replacement of the timing belt. Elimination of the main source of the problem and prevention of further damage.

- Replacement of the oil pressure sensor. To eliminate false readings.

- Turbine diagnostics. Checking for signs of oil starvation.

- Replacement of engine oil and filter. Only with the correct PSA B71 2312 approval.

- Removal/installation of the sump and oil pump. This allowed us to identify the real cause of the pressure drop.

- Replacement of phase control valves (2 pcs.). Restoration of stable gas distribution.

- Replacement of the drive belt. Comprehensive prevention.

- Removal/installation of the vacuum pump. A critical component for safety.

- Engine washing and computer diagnostics. For final control.

Special tools at work

STS specialists used specialised tools for PSA:

- Camshaft and tensioner locks. Ensure accurate phase adjustment when replacing the belt.

- Flywheel pin. Allows the crankshaft to be locked in the desired position.

- Fuel system pressure relief kit. Required for safe removal. Plug set. Used to block channels and prevent dirt from entering. In addition, there are special devices for checking the condition of the timing belt, which allow you to check its residual geometric dimensions.

Advice for owners of cars with PureTech engines

- Change the oil every 8,000–10,000 km. Use only PSA B71 2312 certified oil. Other oils lead to accelerated belt wear.

- Check the oil level regularly. Preferably every day, as the total volume is only 3.25 litres.

- Change the timing belt at least once every 60–80 thousand km. Do not rely on the official intervals of 100–180 thousand km.

- Keep an eye on the pumps. At the slightest sign of pressure drop or brake problems, immediately take the car for diagnostics.

- Monitor the valve clearances. Especially if you use LPG.

Conclusion

The 1.2 PureTech EB2 engine is a striking example of modern ‘environmentally friendly’ engine design: economical, compact, but with low strength reserves. Design issues make it vulnerable in long-term operation.

However, timely maintenance, high-quality materials and professional service — as in the case of our customer — can save the engine from serious consequences and extend its life.

STS Warsaw — we professionally repair modern engines of any complexity.